Fertilizer special for multi-element tobacco and preparation method thereof

A tobacco-specific fertilizer and multi-component technology, which is applied in the field of multi-component tobacco special fertilizer and its preparation, can solve the problems of soil aggregate structure damage, crop product quality degradation, and ecological environment pollution, so as to stimulate crop growth, reduce fertilizer loss, and promote plant growth. The effect of growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

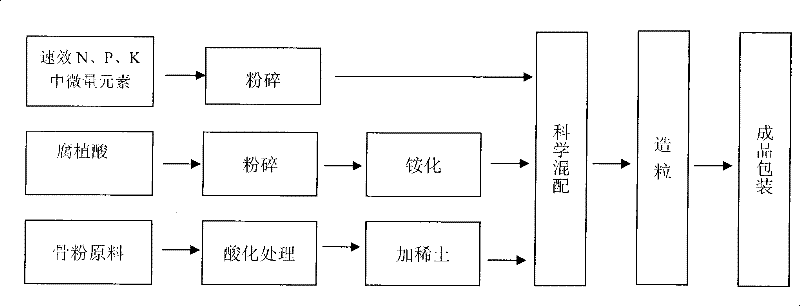

Method used

Image

Examples

Embodiment 1

[0015] Multivariate fertilizer for tobacco: by weight, 12.6 parts of urea, 9.8 parts of diamine phosphate, 39.8 parts of potassium sulfate, 18.0 parts of bone meal, 6.8 parts of humic acid, 1.8 parts of rare earth, 1.7 parts of magnesium and 1.8 parts of sulfur and trace elements The elements boron 0.2 part, iron 0.2 part, zinc 0.2 part, manganese 0.1 part, copper 0.25 part and molybdenum 0.25 part. Wherein the calcium of multivariate tobacco special fertilizer exists in bone meal, and its calcium content is usually 25-30%.

[0016] Preparation method: by weight, 12.6 parts of urea, 9.8 parts of diamine phosphate, 39.8 parts of potassium sulfate, 1.7 parts of magnesium and 1.8 parts of sulfur, 0.2 parts of boron, 0.2 parts of iron, 0.2 parts of zinc and 0.1 parts of manganese 0.25 parts of copper and 0.25 parts of molybdenum are mixed and crushed to 30 meshes, then mixed with 6.8 parts of humic acid, 8 parts of rare earths crushed to 30 meshes and 18.0 parts of acidified bone ...

Embodiment 2

[0020] The difference from Example 1 is:

[0021] Multivariate fertilizer for tobacco: by weight, 13 parts of urea, 10.2 parts of diamine phosphate, 40.2 parts of potassium sulfate, 22.0 parts of bone meal, 7.2 parts of humic acid, 2.2 parts of rare earth, 1.7 parts of magnesium and 2 parts of sulfur and trace elements The elements boron 0.1 part, iron 0.1 part, zinc 0.1 part, manganese 0.1 part, copper 0.25 part and molybdenum 0.25 part.

[0022] Preparation method: in parts by weight, 13 parts of urea, 10.2 parts of diamine phosphate, 40.2 parts of potassium sulfate, 3.7 parts of medium elements of magnesium and sulfur, and 0.9 parts of trace elements of boron, iron, zinc, manganese, copper and molybdenum After mixing, grind to 40 meshes, mix with 7.2 parts of humic acid, 2.2 parts of crushed 40 meshes of rare earth and 22 parts of acidified bone meal, and then granulate by traditional method.

[0023] The humic acid is obtained by pulverizing the lignite into 40 meshes, ad...

Embodiment 3

[0026] The difference from Example 1 is:

[0027] Multivariate fertilizer for tobacco: by weight, 12.8 parts of urea, 10 parts of diamine phosphate, 40 parts of potassium sulfate, 20 parts of bone meal, 7 parts of humic acid, 2 parts of rare earth, 2.1 parts of middle element magnesium and 1.8 parts of sulfur and Trace elements boron 0.1 part, iron 0.1 part, zinc 0.1 part, manganese 0.1 part, copper 0.2 part and molybdenum 0.2 part.

[0028] Preparation method: in parts by weight, 12.8 parts of urea, 10 parts of diamine phosphate, 40 parts of potassium sulfate, 3.9 parts of medium elements and 0.8 parts of trace elements are mixed and pulverized to 35 meshes, then mixed with 7 parts of humic acid and crushed for 35 Mix 2 parts of target rare earth with 20 parts of acidified bone powder and granulate by traditional method.

[0029] The humic acid is obtained by pulverizing lignite into 35 meshes, adding ammonium water with a mass content of 13%, and mixing them, then stacking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com