Electrolytic tin plating solution and electrolytic tin plating method

A technology for electrolysis of tin and plating solution, which is applied to electrolysis components, electrolysis process, circuits, etc., can solve the problems of difficulty in treatment of plating solution wastewater and washing water, and achieve the effects of easy wastewater treatment, preventing deformation, and improving product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] The plating bath was formed using a tin plating solution having the following composition:

[0072] (A) stannous methanesulfonate (as tin ion) 12g / L

[0073] (B)(A) Methanesulfonic acid (as free acid) 50g / L

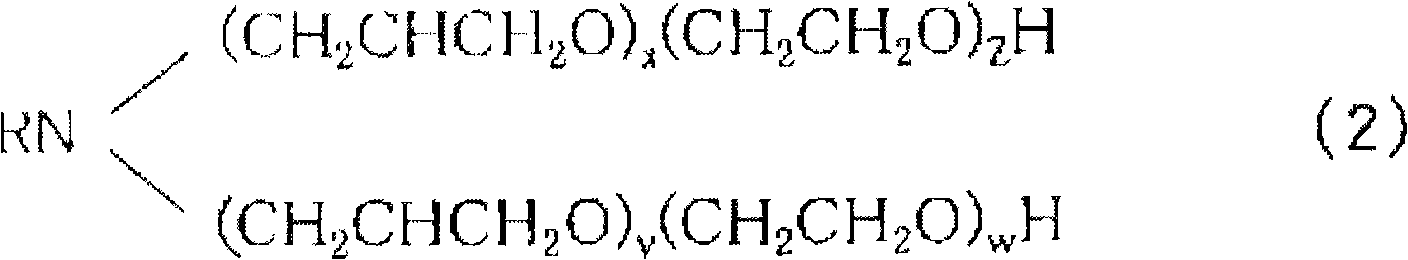

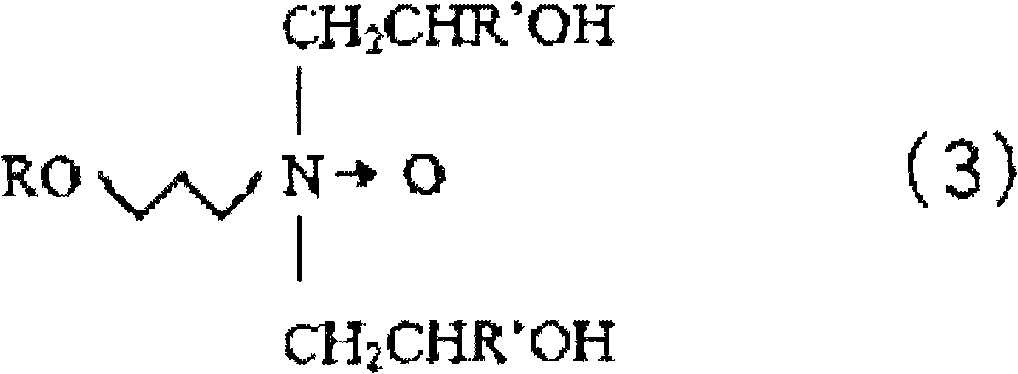

[0074] (C) Amine oxides: derived from ethylene oxide, methyl-, polymers with ethylene oxide, with 2,2'-(imino oxide)bis[ethanol](2:1)N-[3 -(C9-11-isoalkoxy)propyl] ether (oxirane, methyl-, polymerwith oxirane, ether 2, 2'-(oxidoimino)bis[ethanol](2:1)N-[3-(C9 -11-isoalkyloxy)propyl]derived) 10g / L

[0075] (D) Benzylidene acetone 0.4g / L

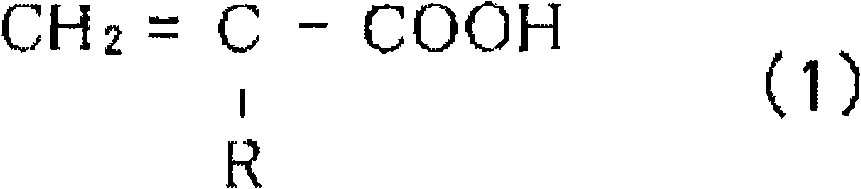

[0076] (E) Methacrylic acid 2g / L

[0077] (F) Sodium 2-naphthol-7-sulfonate 0.5g / L

[0078] (G) Potassium hydroquinone sulfonate 2g / L

[0079] (H) Distilled water balance

[0080] Under the conditions shown below, tin barrel plating was performed on nickel-plated chip resistors with 1 L of tin plating solution, and then various evaluations were performed. The results are shown in Table 1.

[0081] barrel

[0082] Platin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap