Electric fan for sewing machine

A technology of electric fan and sewing machine, applied in sewing machine components, sewing equipment, mechanical equipment, etc., can solve the problems of resource waste, high cost, stuffy workshop, etc., and achieve the effects of improving work efficiency, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

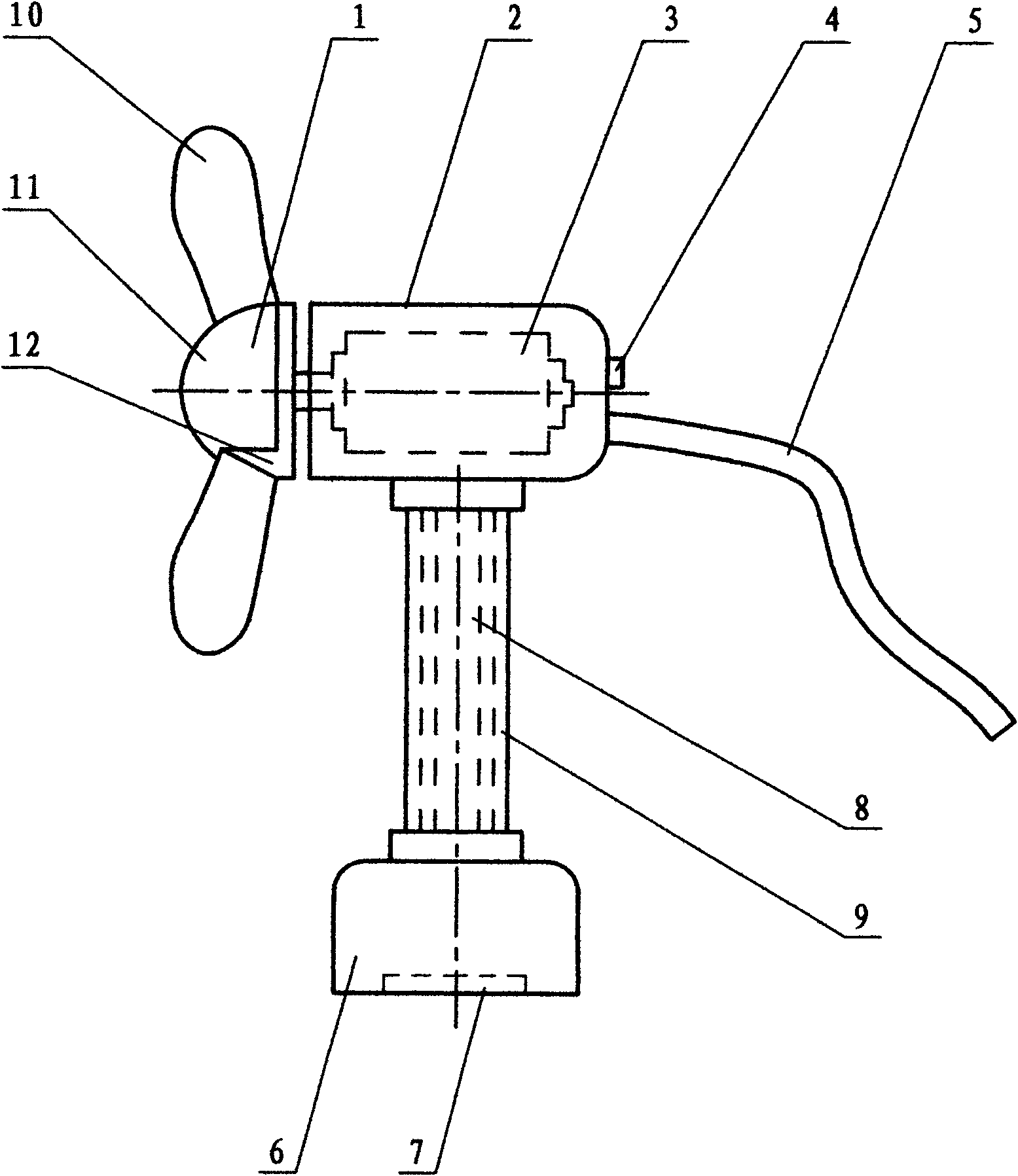

[0024] Embodiment 1: as figure 1 , an electric fan for sewing machines, comprising a fan head 1, a casing 2, a motor 3, a switch 4, a power cord 5, a base 6, and a pole 8, the motor 3 is arranged in the casing 2, and the fan head 1 is arranged on the extension of the motor 3 At the end of the output shaft, the bottom surface of the base 6 is provided with a magnet 7, and the pole 8 is connected to the shell 2 and the base 6. One end of the power cord 5 is connected to the motor 3, and the other end is directly connected to the external power supply (motor switch). The device has a simple structure. The bottom surface of base 6 is provided with magnet 7, and electric fan can be directly adsorbed on the sewing machine body, and pole 8 is a metal hose, which can be bent in any direction, so that fan head 1 is blown toward the operator, and is easy to install. A bellows 9 is established outside the pole 8, which is decorative and attractive. Switch 4 controls the motor to rotate...

Embodiment 2

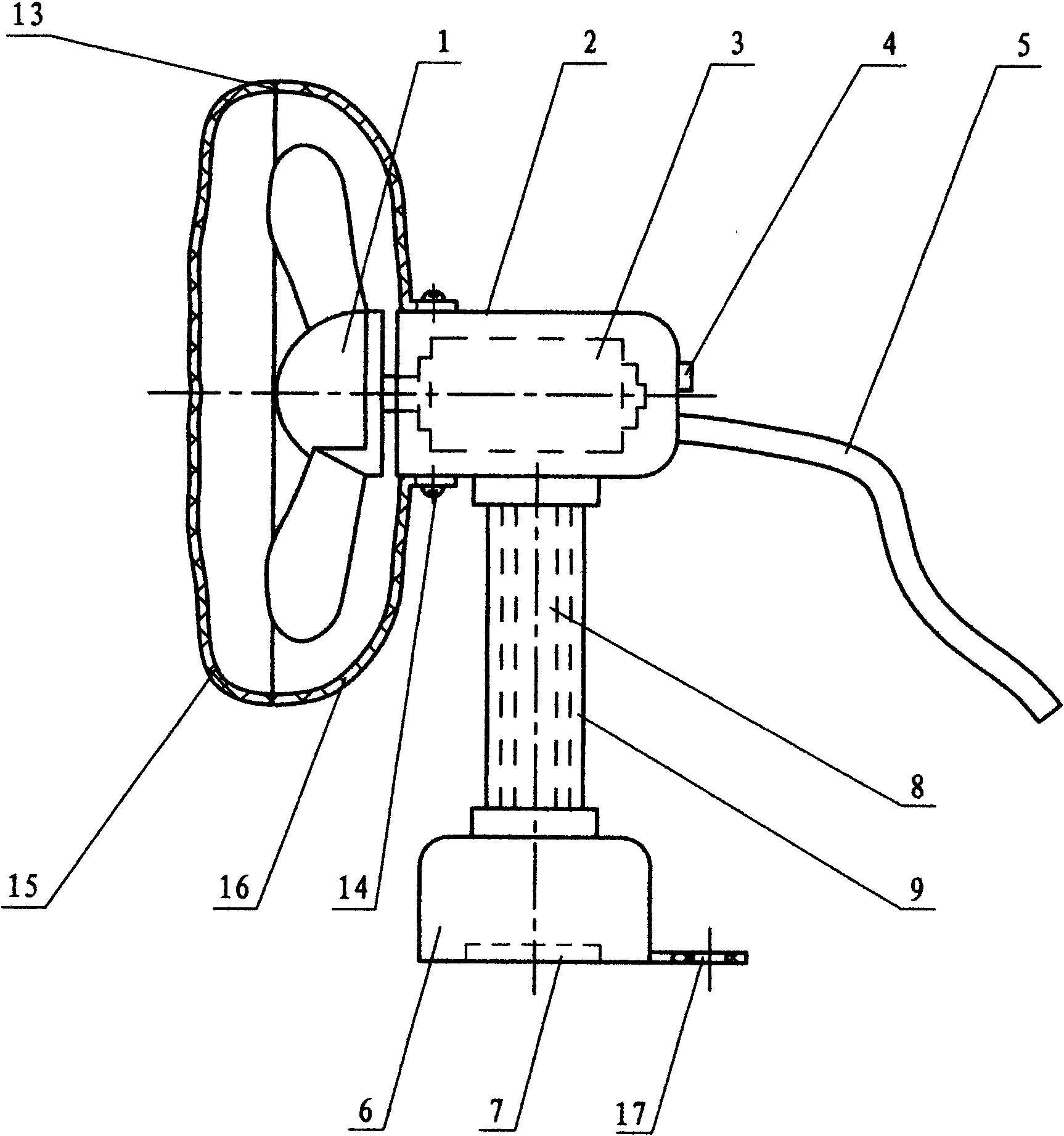

[0025] Embodiment 2: as figure 2 , an electric fan for sewing machines, when the fan head 1 is molded with integral plastic, a fan cover 13 is added on the outside so that the operator cannot touch the fan head 1, which is safer. The fan cover 13 is made up of a front cover 15 and a rear cover 16, and is locked on the casing 2 with screws 14. Fan cover 13 is net shape, and many ventilation grooves are arranged above. The bottom surface of the base 6 is provided with a mounting hole 17. When the magnet is not installed, the base 6 can be locked on the sewing machine with screws, which saves costs. Other structures are the same as in Embodiment 1, and will not be described in detail again.

Embodiment 3

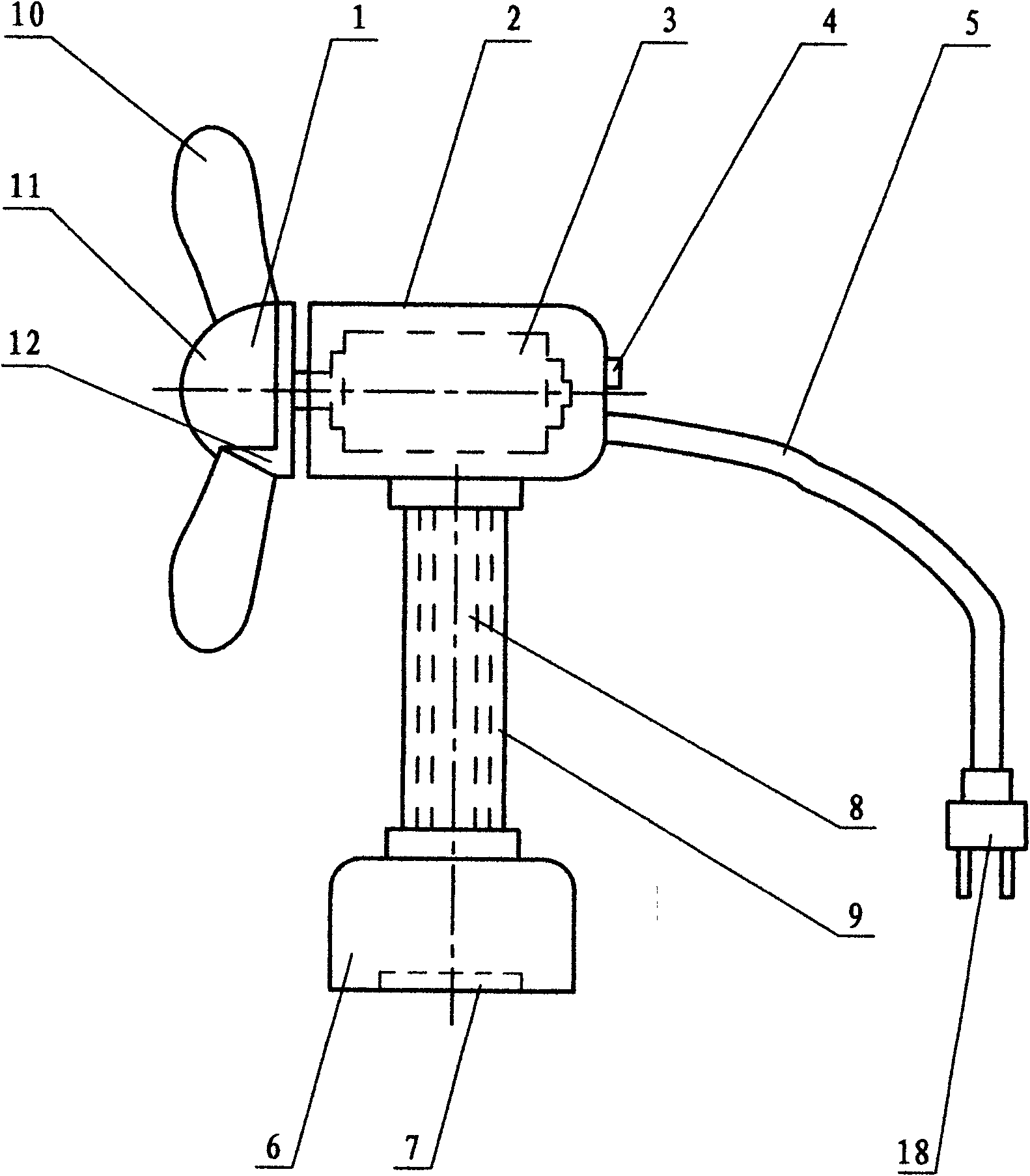

[0026] Embodiment 3: as image 3 , an electric fan for sewing machines, one end of a power cord 5 connected to an external power supply is provided with a two-pin two-pin plug 18, which can also be a three-pin plug, which is more convenient to install. Other structures are the same as in Embodiment 1, and will not be described in detail again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com