A trolley grate plate of a ring cooler

A technology of ring cooler and grate plate, applied in the field of ring cooler, can solve the problems of leakage of steel plate 4a, drop of roasted pellets, poor welding performance, etc., and achieve the effect of preventing leakage from gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention provides a trolley grate plate of an annular cooler, which is used to solve the problem of material leakage between the grate plates.

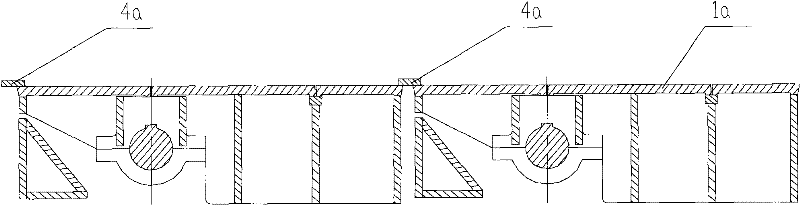

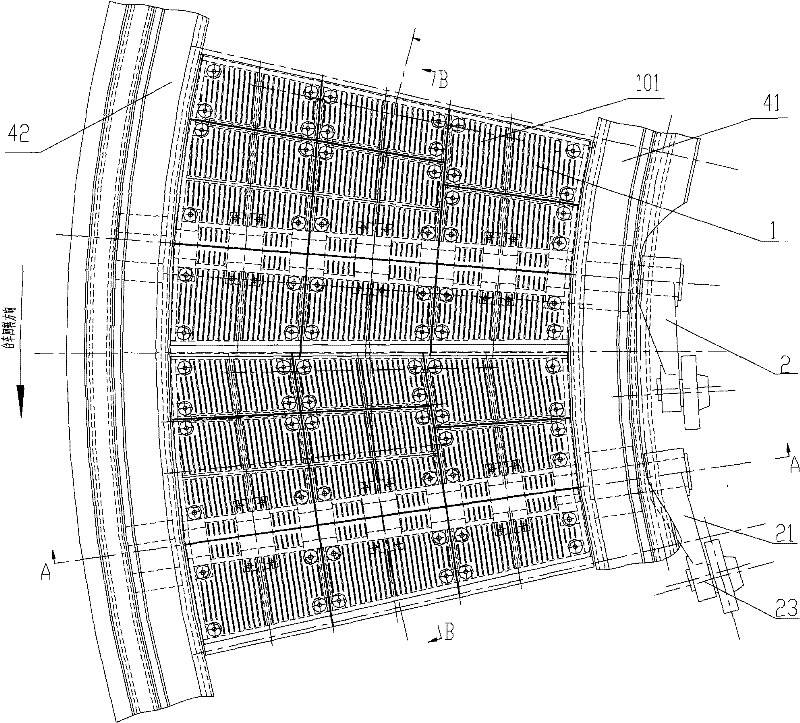

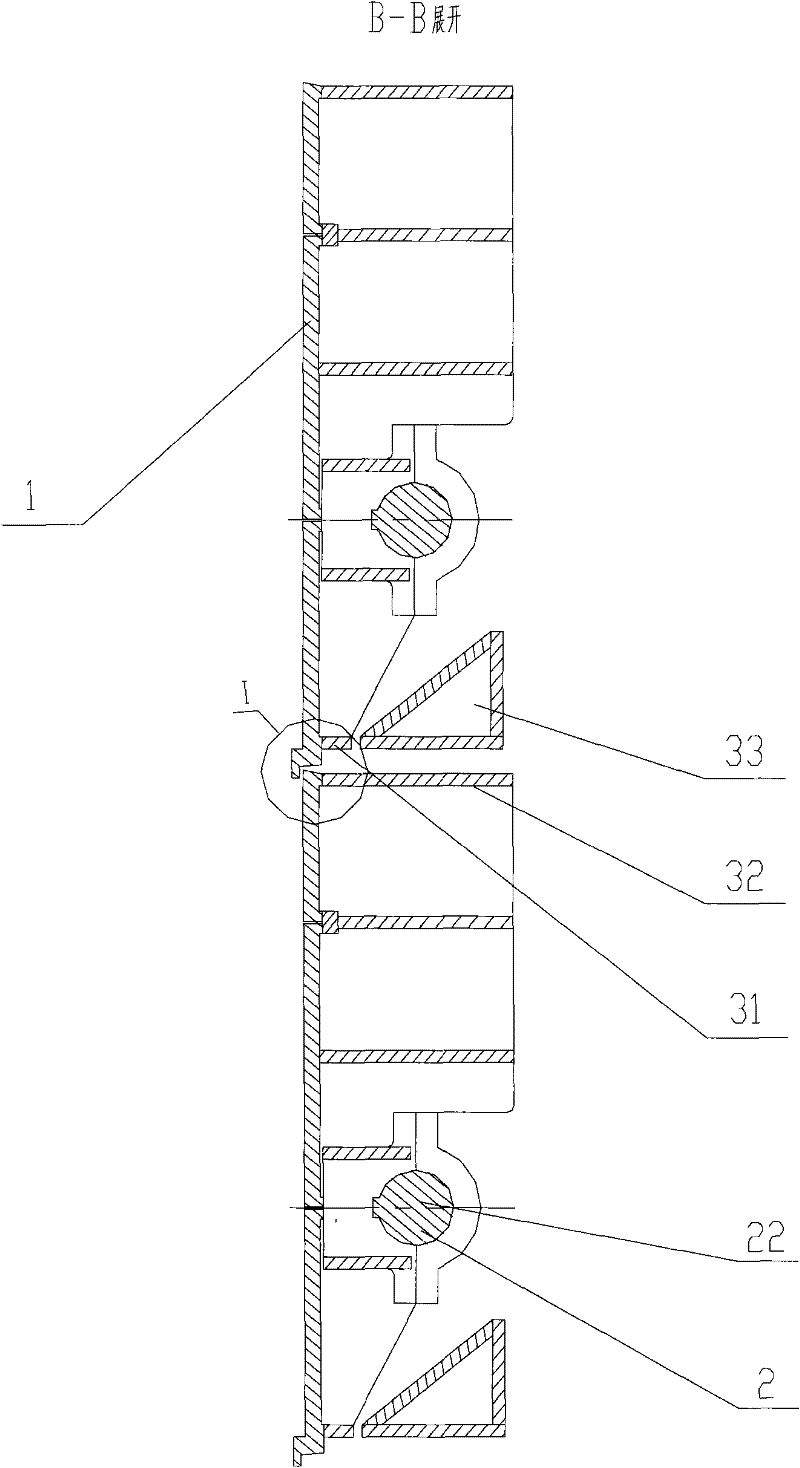

[0024] see Figure 2 to Figure 5 , figure 2 It is the front view of the trolley grate plate of the annular cooler described in the embodiment of the present invention; image 3 yes figure 1 The B-B direction sectional view shown; Figure 4 yes image 3 The enlarged view of part I shown; Figure 5 yes figure 1 Shown is the A-A sectional view.

[0025] The grate plate of the trolley of the annular cooler described in the embodiment of the present invention makes the grate plate 1 in a horizontal state through the rocker device 2 . The grate plate 1 includes a grate plate base 11 and a cover plate 12 integrally formed with the grate plate base 11 .

[0026] figure 2 The direction indicated by the arrow is the running direction of the annular cooler.

[0027] The cover plate 12 is specifically arranged at the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com