Method for remanufacturing photosensitive drum into another photosensitive drum

One kind of photosensitive drum and another kind of technology are applied in the fields of optics, solid waste removal, electric recording technology using charge patterns, etc., which can solve the problems of waste of resources, occupation of enterprise funds, and low demand for A-type photosensitive drums. Achieving the effect of avoiding waste and increasing production flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

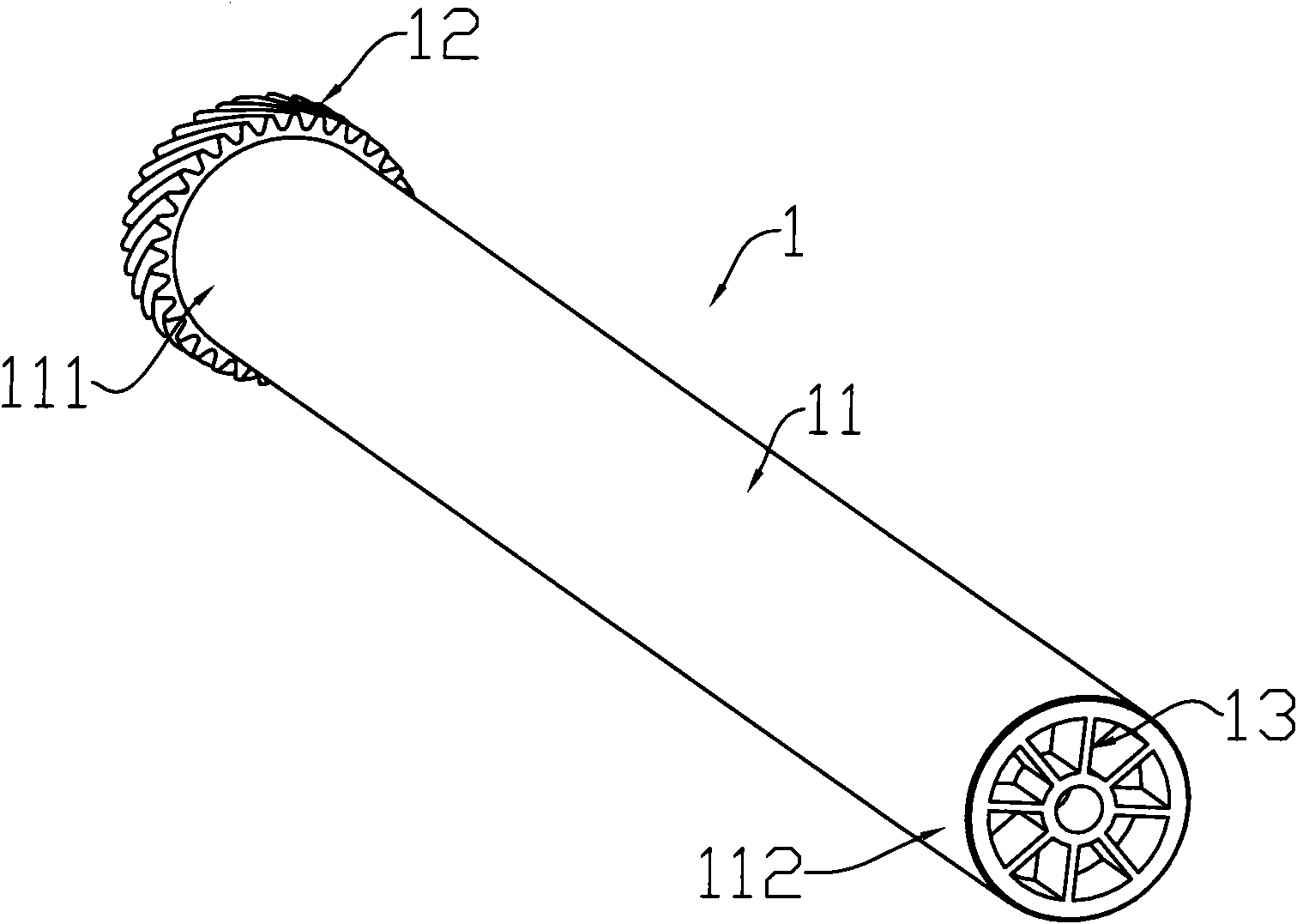

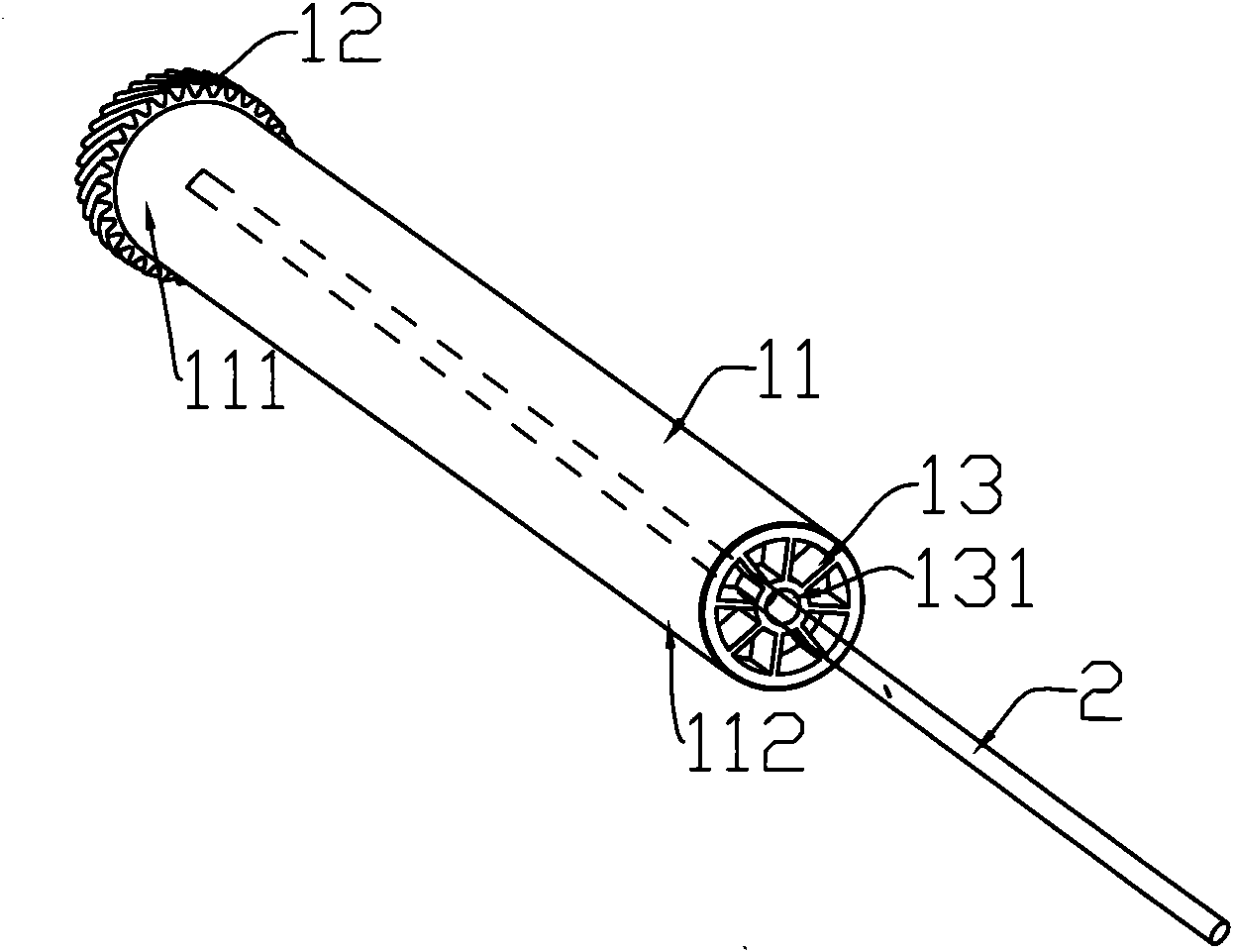

[0023] figure 1 is a structural schematic diagram of a recycled photosensitive drum, which is referred to as the first photosensitive drum 1 hereinafter. The first photosensitive drum 1 includes a drum body 11 , a drum gear 12 mounted on one end 111 of the drum body 11 and a component 13 mounted on the other end 112 of the drum body 11 . The drum body of the first type photosensitive drum 1 has the same diameter and drum surface characteristics as that of another type of photosensitive drum. For the convenience of description, the other type of photosensitive drum will be referred to as the second type photosensitive drum hereinafter. The structure of drum gear 2 and component 2 of the second photosensitive drum is different from that of the first photosensitive drum 1 .

[0024] In order to remanufacture the first type of photosensitive drum 1 into the second type of photosensitive drum, the following methods can be used:

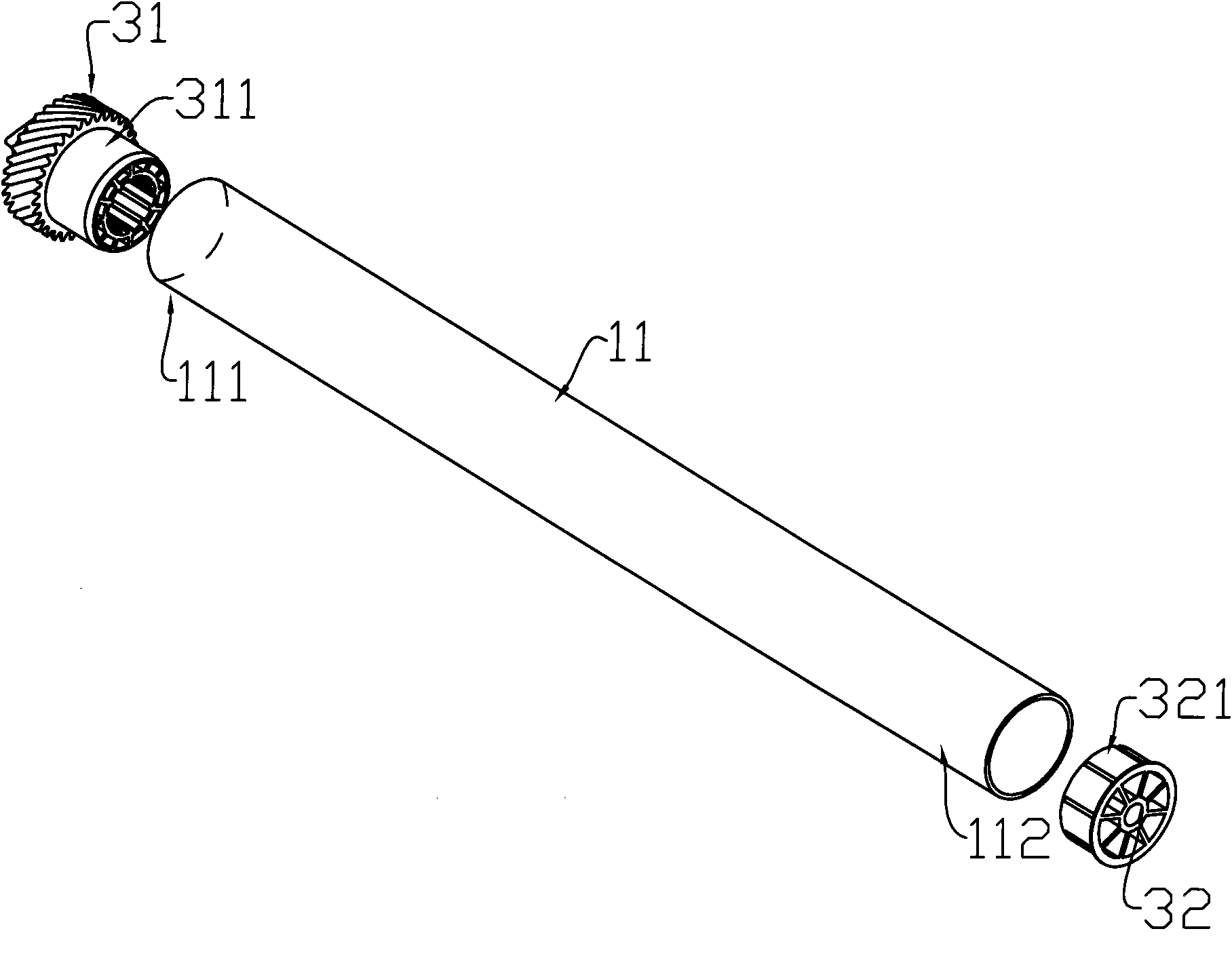

[0025] A. Disassemble the drum gear one 12 and par...

Embodiment 2

[0033] Although the drum body of the first photosensitive drum in this example is the same as the drum body diameter and drum surface characteristics of the second photosensitive drum, the lengths are different. In this case, the Figure 5 As shown, first the end 112 of the mounting part 13 of the drum body 11 of the first photosensitive drum 1 is cut off, so that the drum body 11 of the first photosensitive drum 1 has the same length as the drum body of the second photosensitive drum , and then remove the drum gear one 12 installed on the other end 111 of the drum body 11 of the first photosensitive drum 1, and then install the drum gear two and part two suitable for the second photosensitive drum on the cut-off drum body ends.

[0034] Of course, when the drum body 11 is shortened, one end 111 of the belt drum gear one 12 can also be cut off earlier, and then the part one 13 is pulled down, which has no essential difference.

[0035] Wherein, the dismantling method of drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com