Production method of tomato sauce and production flow line system of tomato sauce

A production line and production method technology, applied in the fields of application, food preparation, food science, etc., can solve the problems such as the inability to effectively manage the equipment, the inability to summarize and feedback the operation status of the equipment, etc., to speed up the filling efficiency and facilitate the attachment Labels, effects that reduce impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

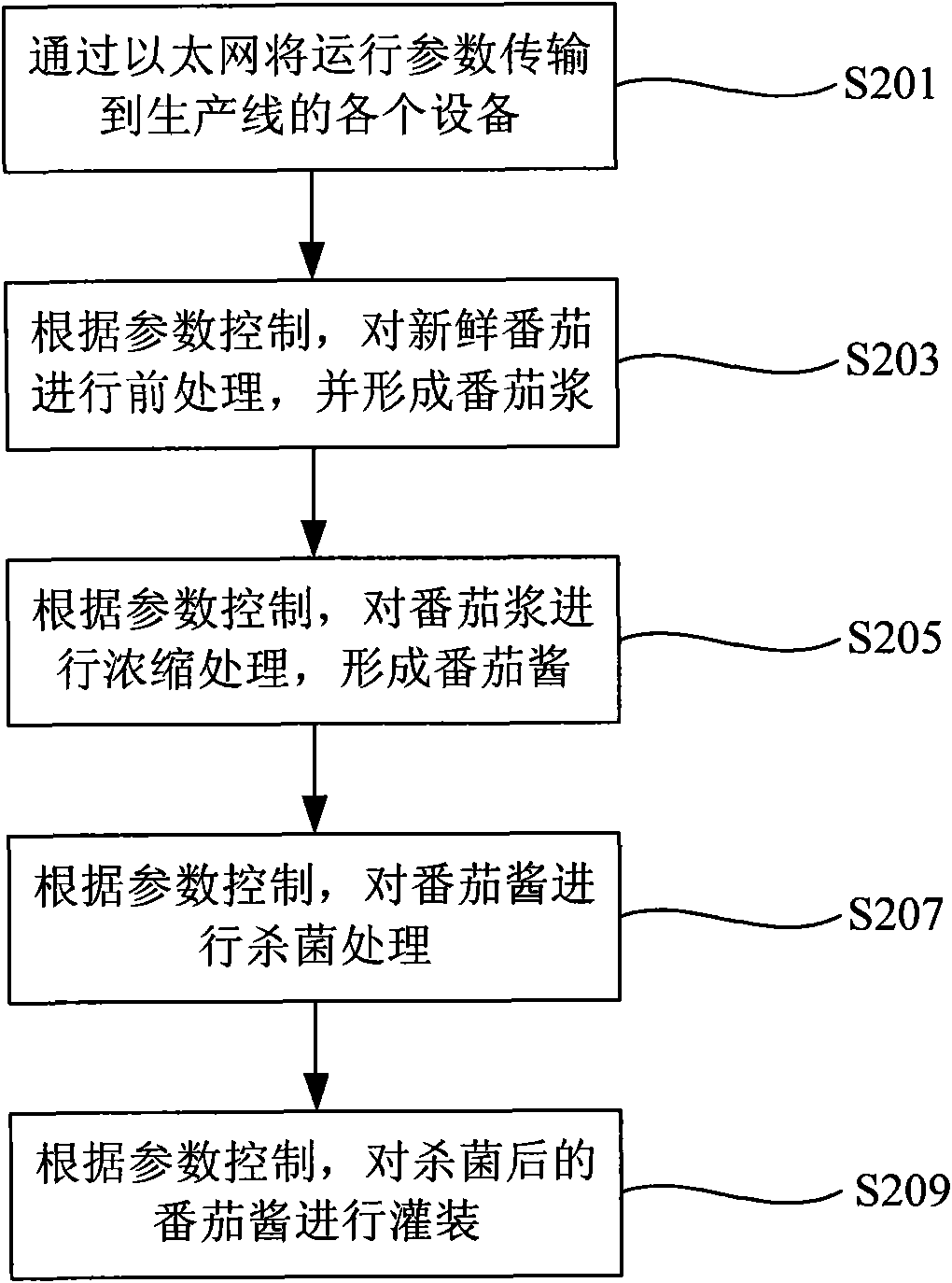

[0035] See figure 2 , which is a flow chart of a method for producing tomato paste according to the embodiment of the present invention, which comprises the following steps:

[0036] S201, transmitting the operating parameters to each device of the production line through Ethernet.

[0037] S203, according to parameter control, perform pretreatment on fresh tomatoes, and form tomato pulp.

[0038] S205. Concentrating the tomato pulp according to parameter control to form tomato paste.

[0039] S207, according to the parameter control, sterilize the tomato paste.

[0040] S209, filling the sterilized tomato paste according to parameter control.

[0041] Among them, the parameters transmitted through Ethernet are used to control the operation status of each equipment in the production line, such as the transmission speed of fresh tomatoes, the heating temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com