Heavy power and free overhead conveyer

A suspension conveyor and accumulation technology, which is applied in the field of heavy accumulation suspension conveyors, can solve the problems of unsuitable conveying of heavy conveying materials, inconvenient installation and maintenance, and low bearing capacity, and achieves simple structure, low cost, and bearing capacity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

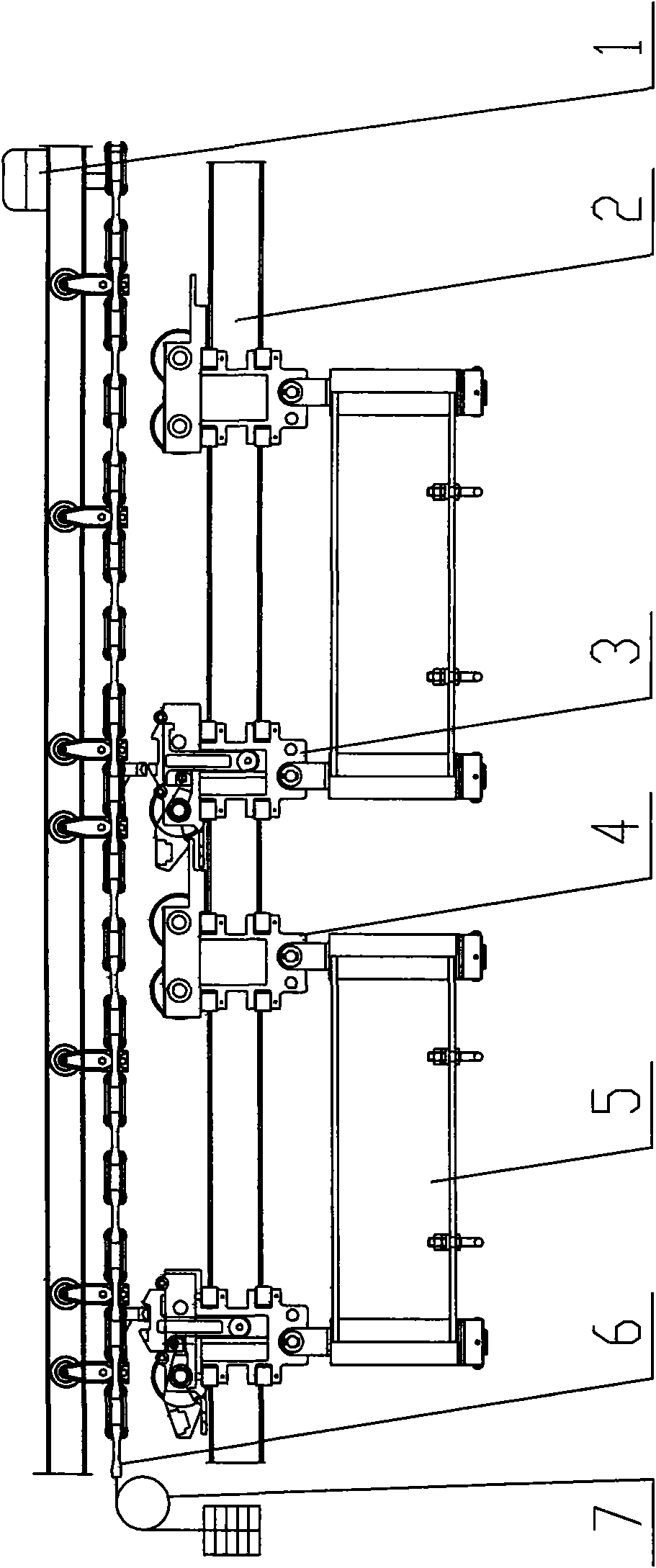

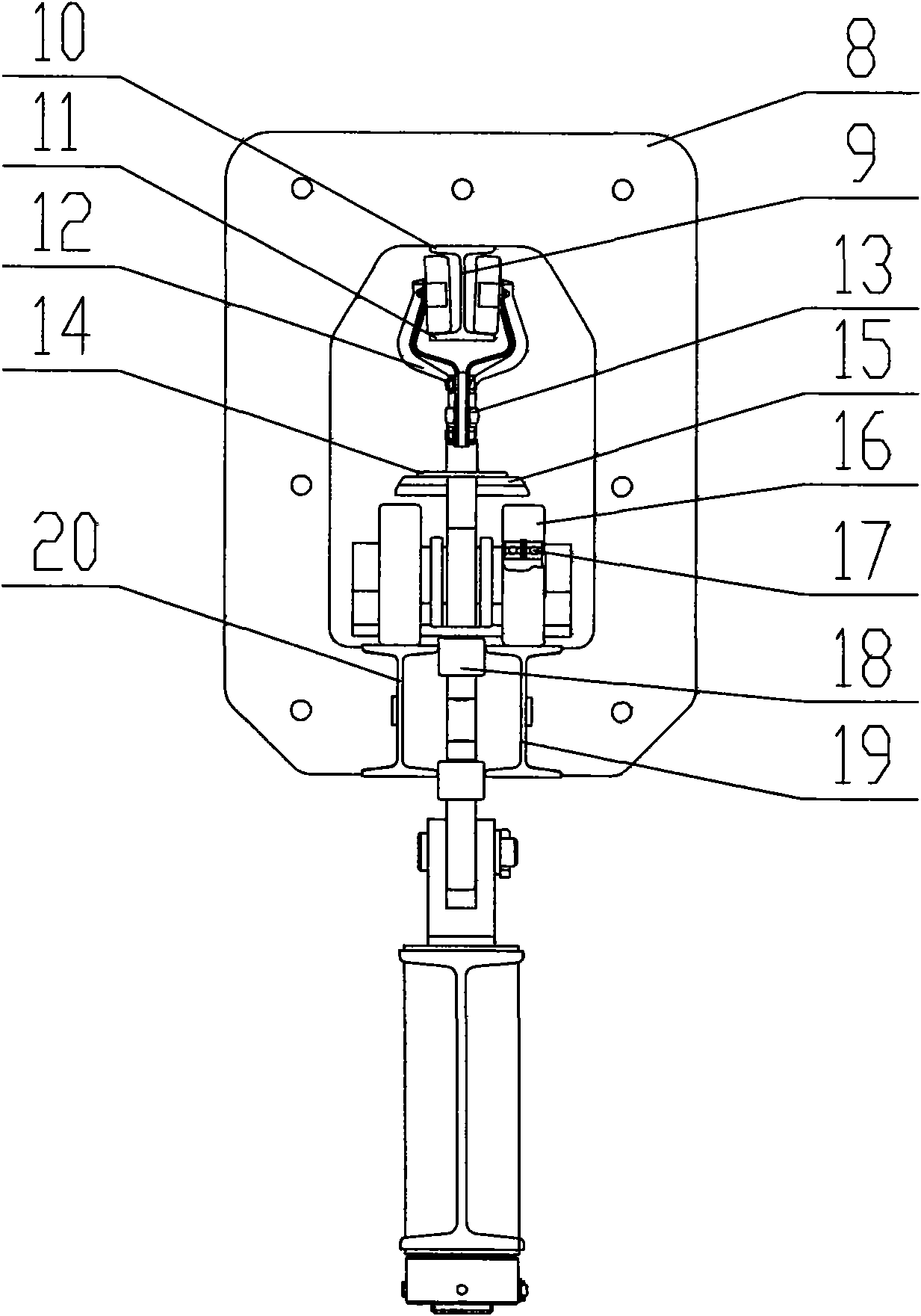

[0010] Heavy-duty accumulation and release suspension conveyor, including drive device 1, traction chain 6, tensioning device 7, track system 2, front trolley 3, rear trolley 4 and load beam 5, the track system 2 is composed of traction rails 9, first The bearing rail 19, the second bearing rail 20 and the downwardly opening C-shaped bracket are formed. The upper wing plate 10 of the I-shaped traction rail 9 is fixedly welded to the inner top surface of the C-shaped bracket, and the first I-shaped bracket is welded together. The carrying rail 19 and the I-shaped second carrying rail 20 are arranged in parallel and juxtaposed at the opening of the downwardly opening C-shaped bracket. The right open end of the bracket is fixed and welded together, the left side web of the second bearing rail 20 and the left inner sides of the upper and lower wings are fixed and welded together with the left open end of the C-shaped bracket, and the first bearing rail A car body 18 is movably arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com