Measurement method of internal stress of electrical deposition layer

An electrodeposited layer, internal stress technology, applied in measuring devices, material analysis by optical means, instruments, etc., can solve problems such as bubbles, cracks, stress corrosion, etc., and achieve the effect of simple and accurate measurement steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

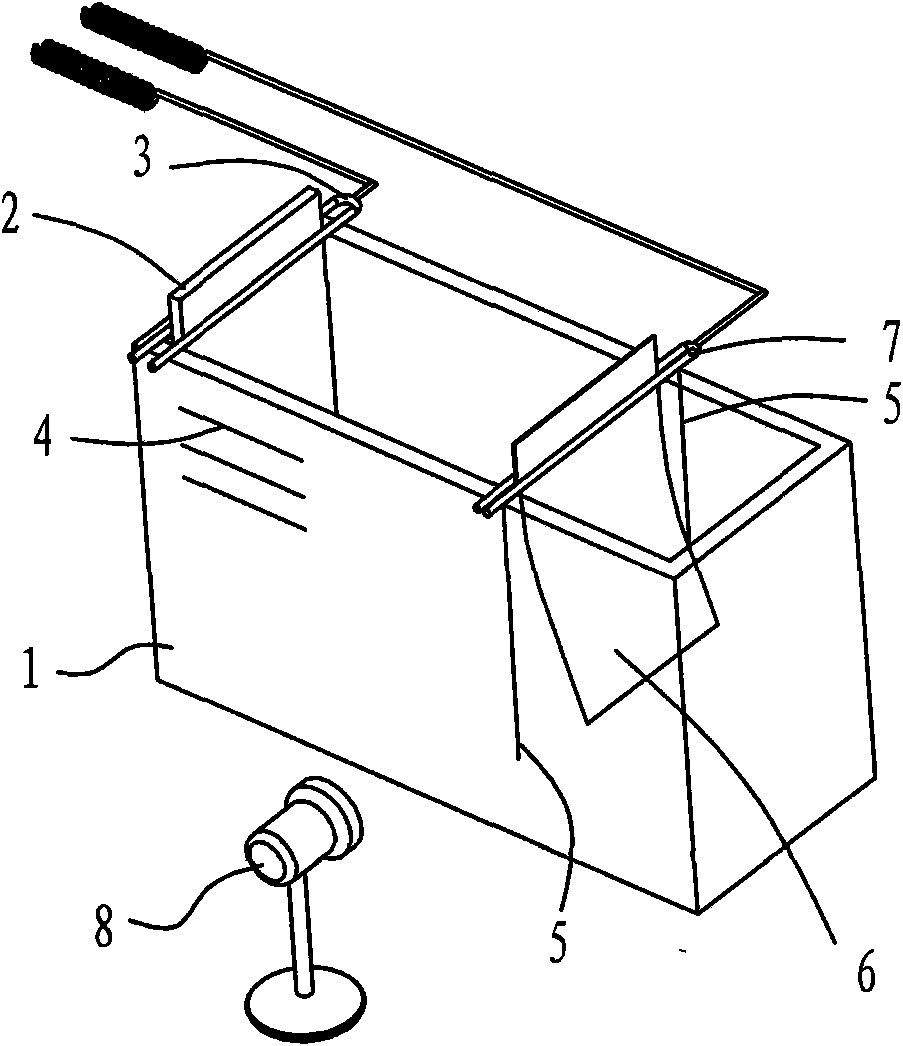

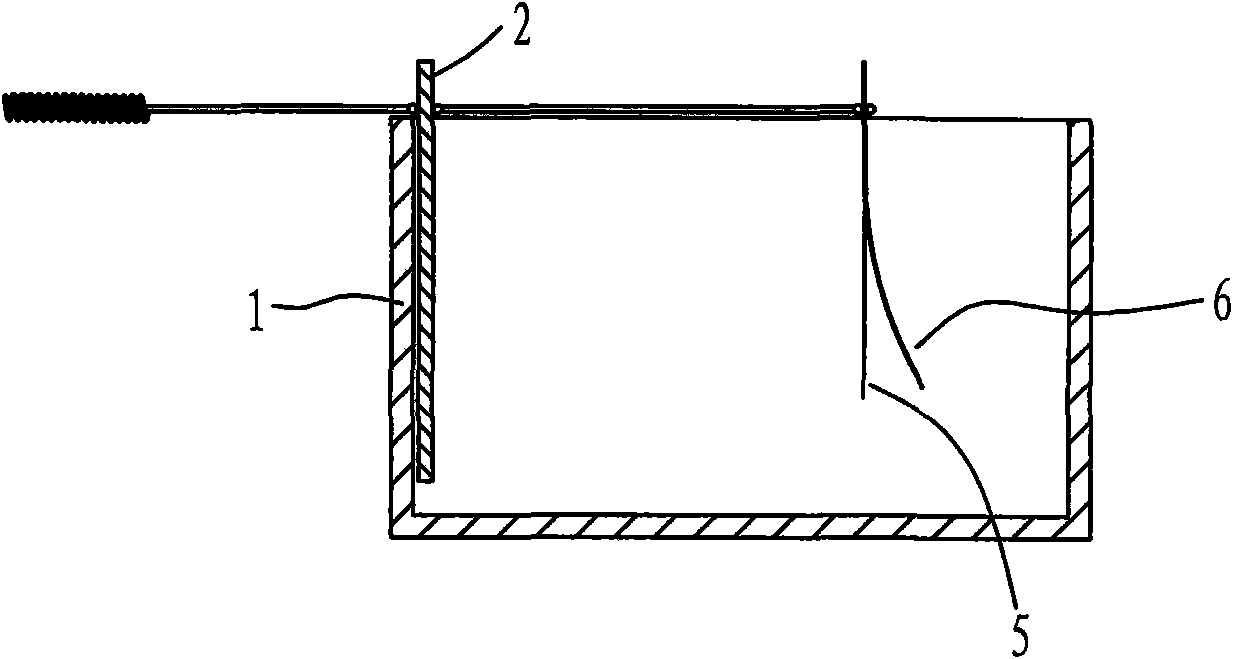

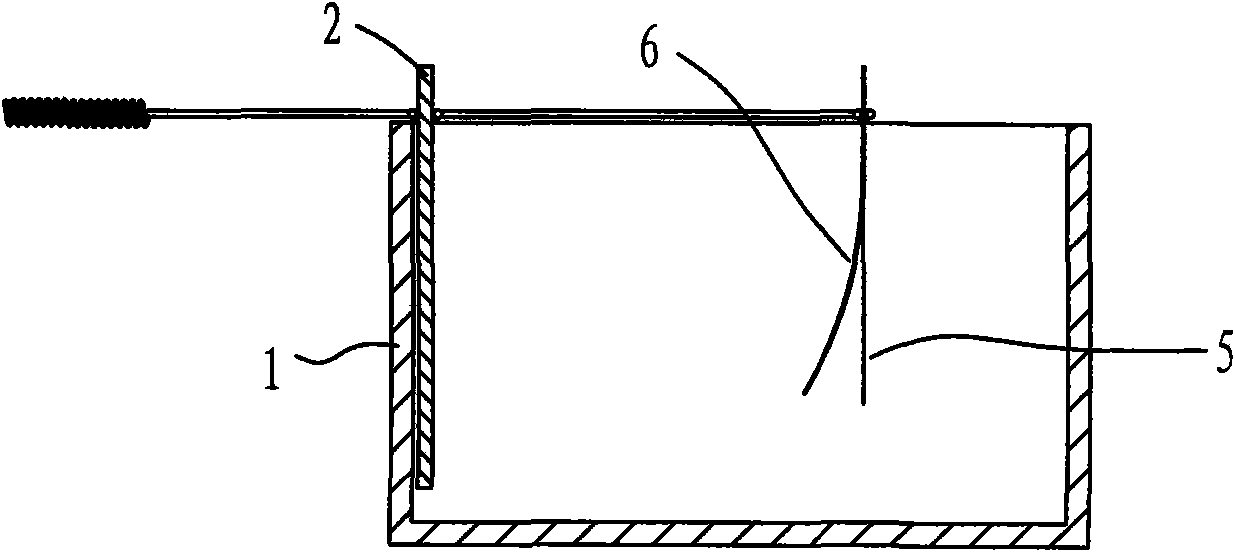

[0018] A method for measuring the internal stress of the deposited layer, a, take a transparent organic glass electroplating tank 1 with an internal size of 200mmX150mmX10mm, and install an electroplating solution inside, immerse the anode test piece 2 in the electroplating tank, the top of the anode test piece is provided with a conductive clip 3, and the electroplating tank The tank wall is provided with a horizontal scale line 4 indicating the depth of the electroplating solution in the tank, and the electroplating tank wall is also provided with a scale positioning line 5, which is perpendicular to the horizontal scale line 4 of the plating solution depth.

[0019] b. Take the 120mmX8mm cathode test piece 6, the cathode test piece 6 is a copper piece, and anneal the copper piece at 600-800°C for 40 minutes before the test to eliminate the residual stress, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com