Wire feeding/drawing device and method thereof

A technology for pulling and passing wires, which is applied in the direction of conveyor objects, transportation and packaging, electrical components, etc. It can solve the problems of smoothness of image wire feeding and increase the difficulty of wire feeding, so as to solve scratches, improve efficiency, The effect of improving fluency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

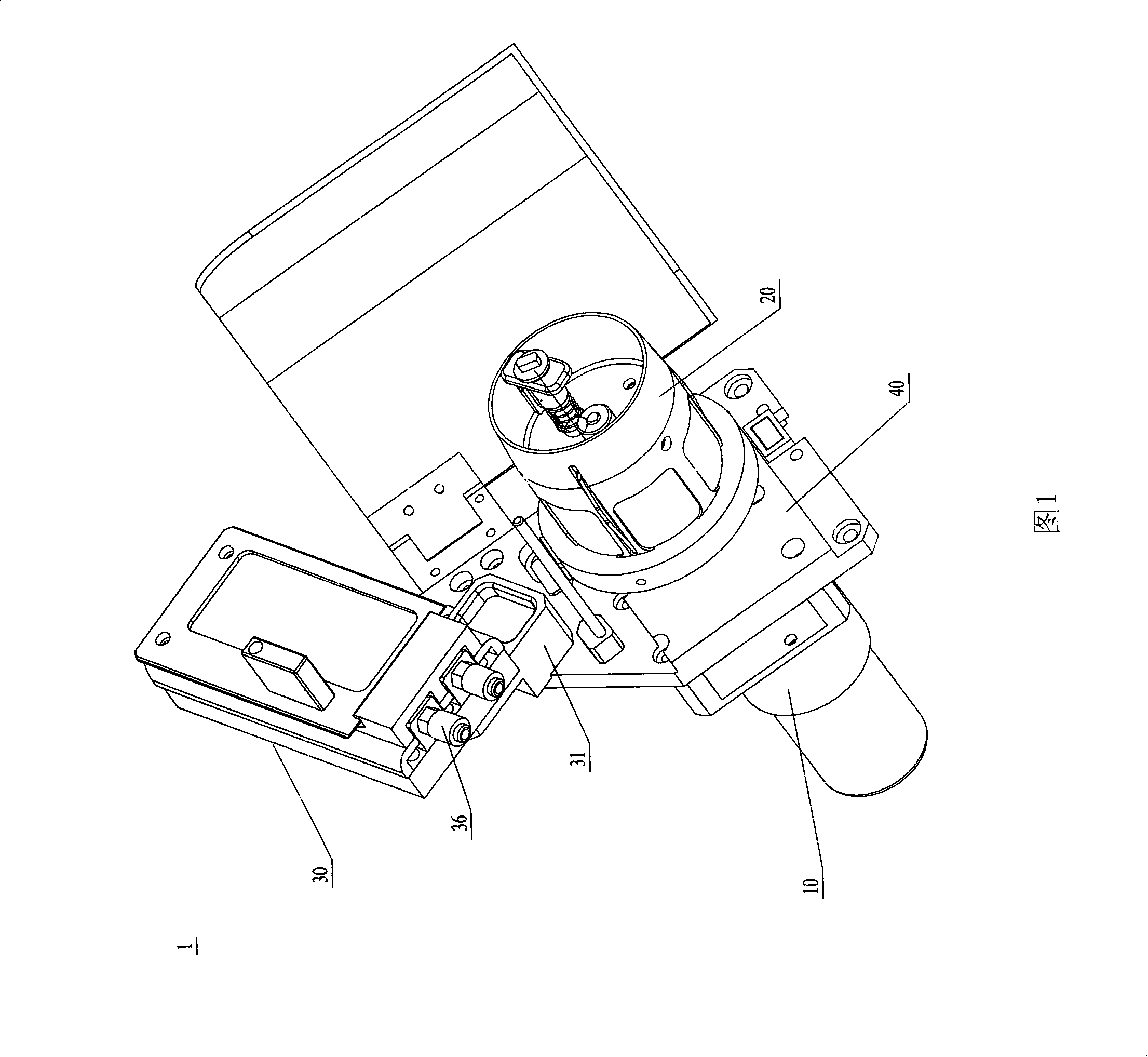

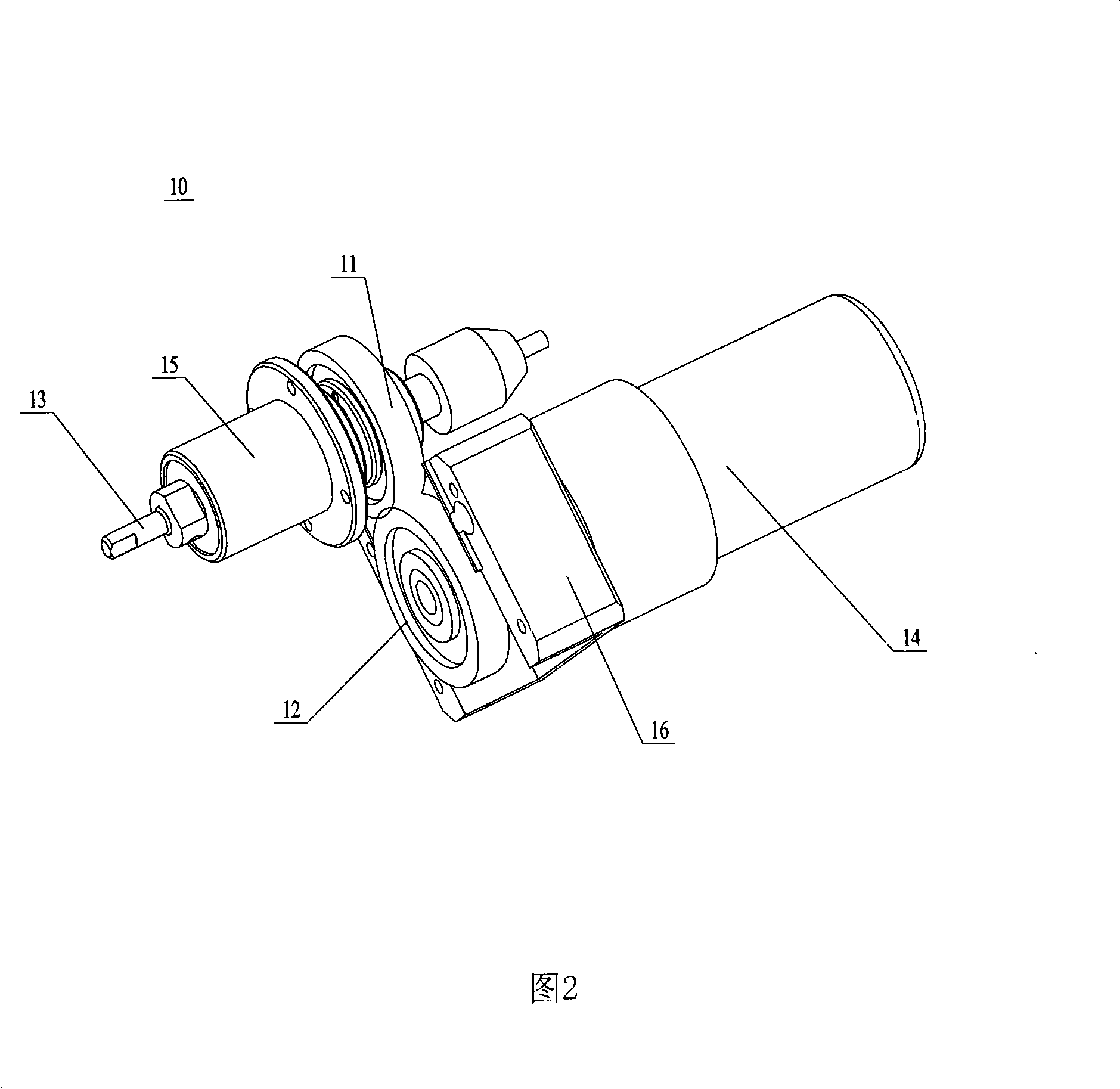

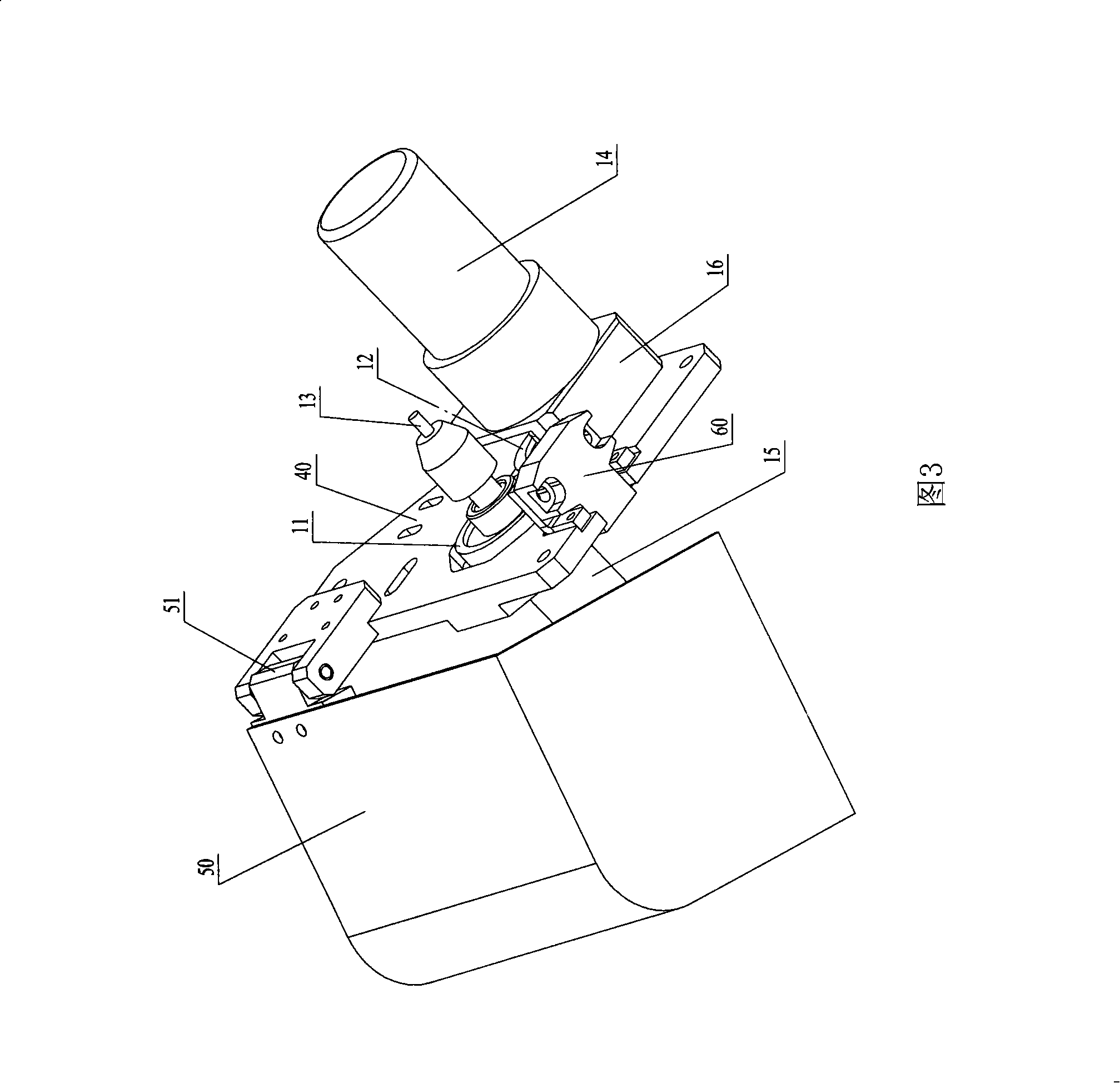

[0028] As shown in Figure 1, it is a structural schematic diagram of the wire sending and pulling device of the present invention. This wire sending and pulling device 1 is used for the gold wire delivery for bonding in the semiconductor LED full-automatic gold ball wire bonding machine, that is, for sending the gold wire to the soldering machine. A wire machine, comprising: a motor assembly 10, a bobbin assembly 20 for assembling a gold wire coil (not shown), a wire assembly 30 passing through a gold wire, and a mounting plate 40, wherein the motor assembly 10 and the bobbin assembly 20 is fixed on the mounting plate 40, the wire assembly 30 is fixed on the mounting plate 40 through an adapter plate 31, and the wire assembly 30 and the bobbin assembly 20 are located on the same side of the mounting plate 40, so as to benefit from the coil bobbi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com