Electron beam sterilizer

A technology of electron beam and sterilization device, applied in irradiation device, packaging sterilization, nuclear engineering, etc., can solve the problem of no sterilization effect and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

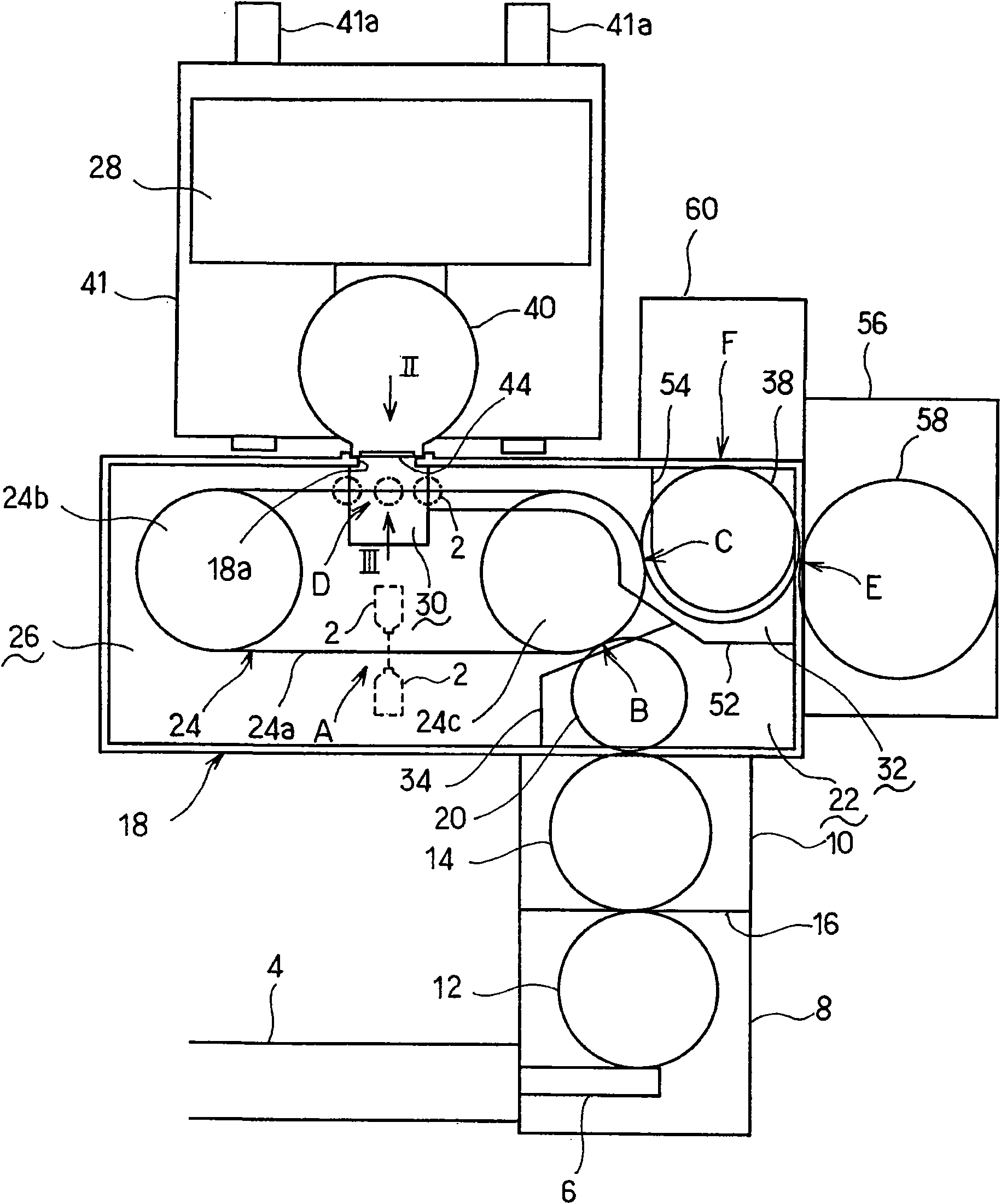

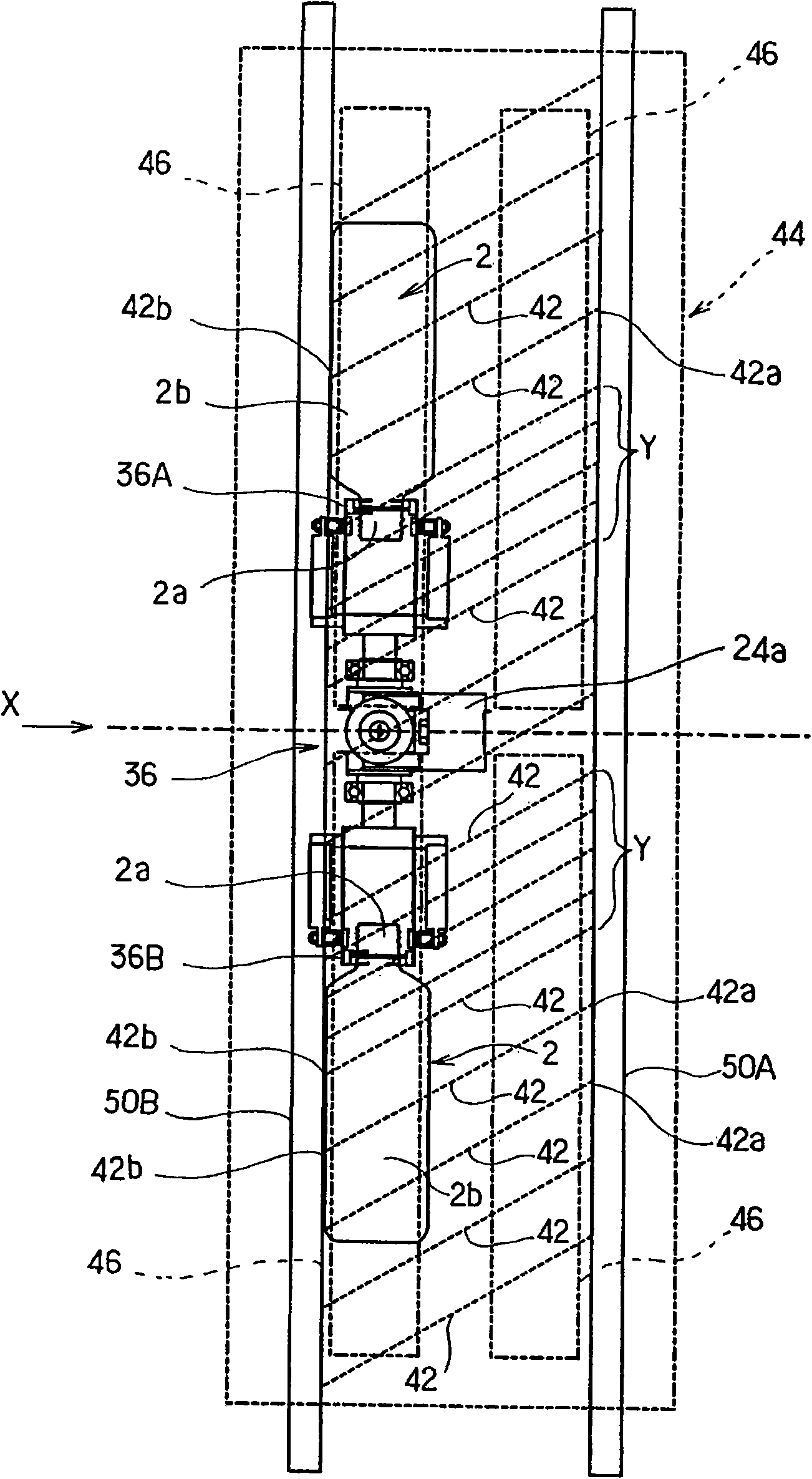

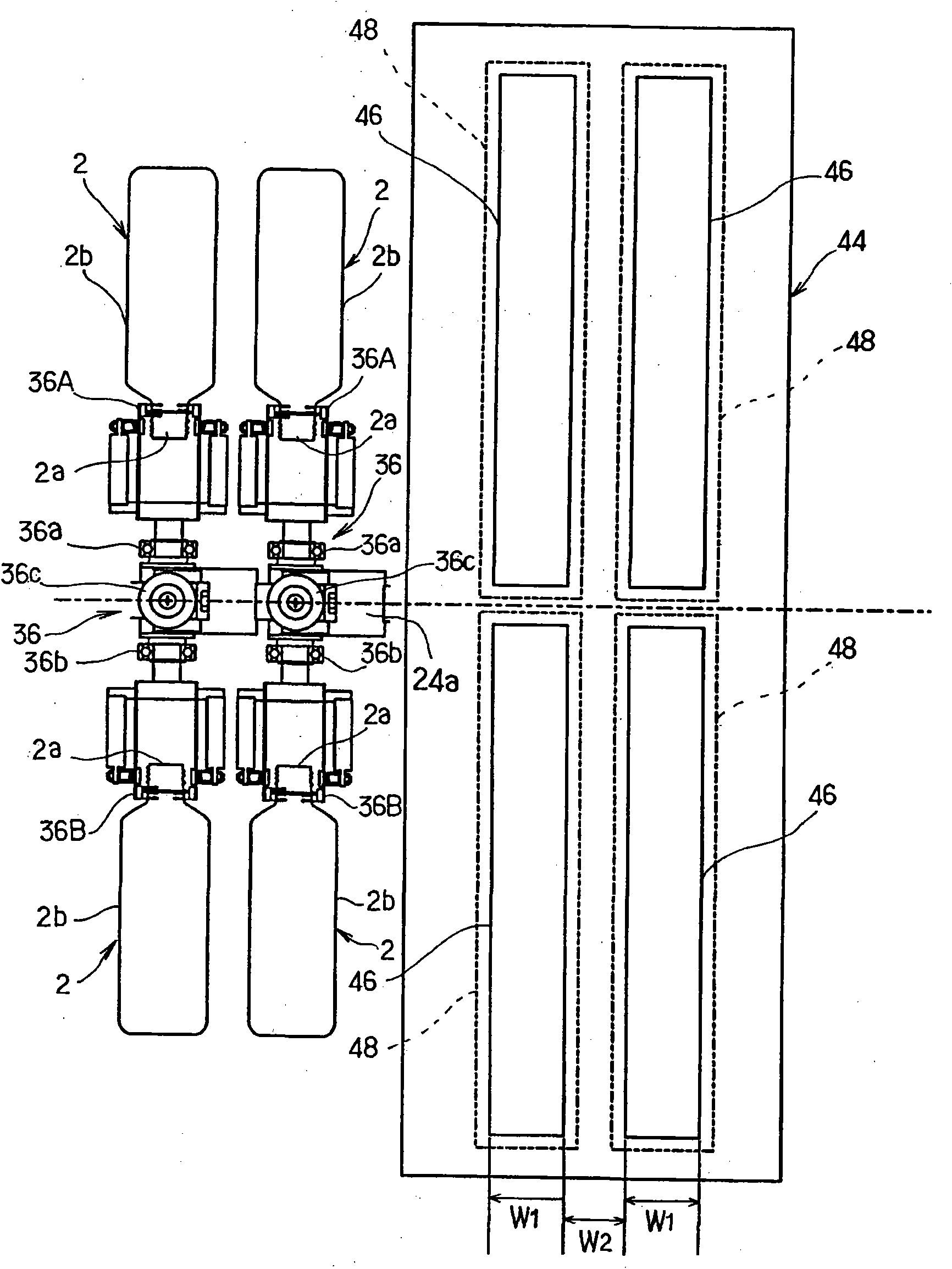

[0018] The present invention will be described below through the embodiments shown in the accompanying drawings. Sterilization is performed in the electron beam sterilizer of this embodiment, and in the subsequent steps, the container 2 (refer to figure 2 , image 3 ) are resin containers such as plastic bottles. The containers 2 are conveyed continuously by the air conveyor 4, and are fed into the introduction chamber while being cut at predetermined intervals by the transverse feed screw 6.

[0019] Above-mentioned introduction chamber is divided into two chambers (the first chamber 8 and the 2nd introduction chamber 10), respectively in each chamber 8,10 inside, is provided with the rotary wheel (the first rotation wheel) that has container holding mechanism (not shown in the figure). wheel 12 and the second rotating wheel 14). The containers 2 carried into the introduction chambers 8 and 10 are sequentially handed over to the rotating wheels 12 and 14 in the respective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com