Device for adjusting oil pressure of engine

A technology of engine oil and pressure regulation, applied in the direction of pressure lubrication of lubricating pumps, can solve problems affecting engine economy, reliability, oil can not be too high, multi-engine power, etc., to improve fuel economy and reduce pump oil. Pulsation effect, good effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

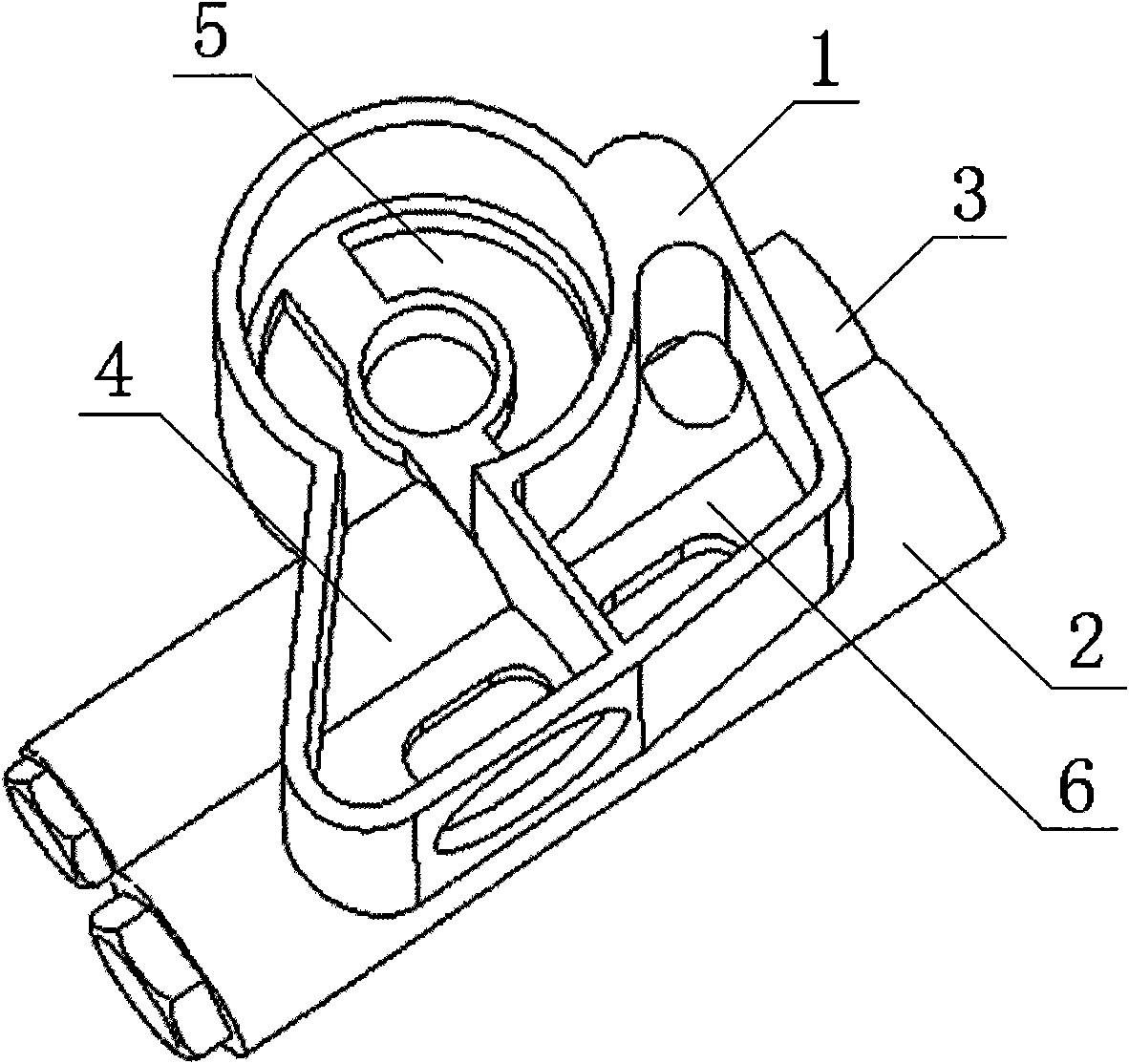

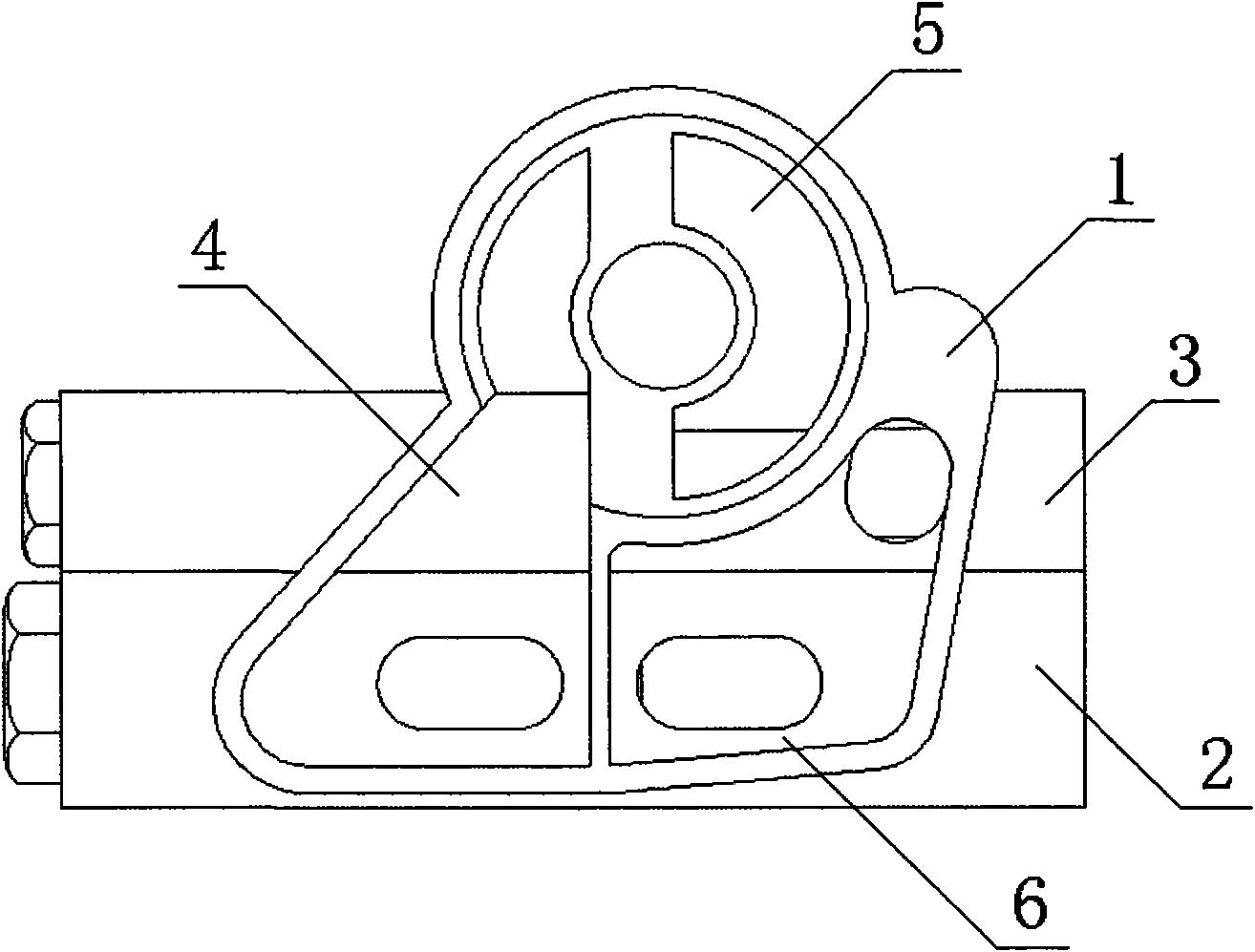

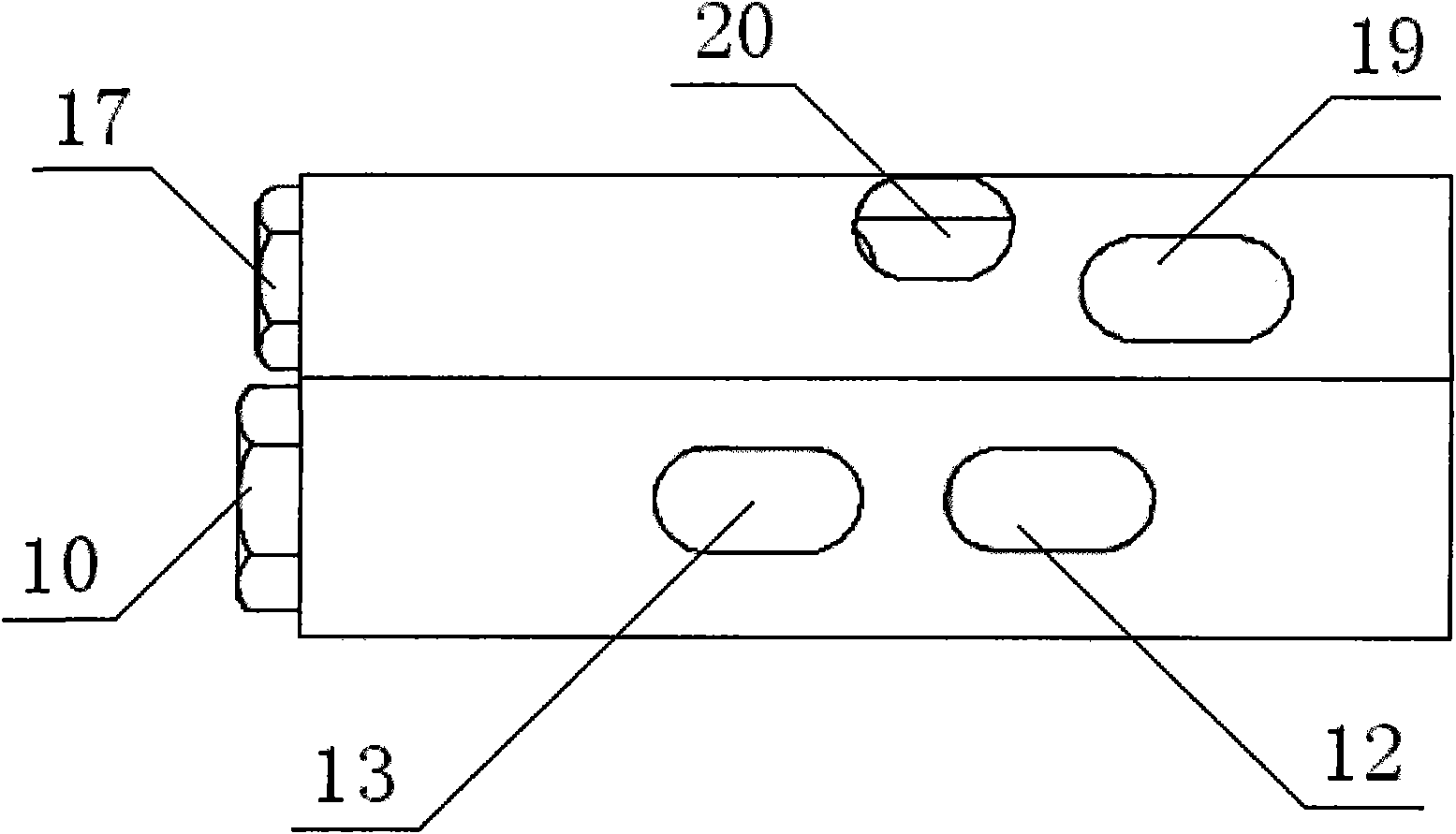

[0022] figure 1 Shown is a three-dimensional structure schematic diagram of the engine oil pressure regulating device of the present invention, figure 2 Shown is a structural schematic diagram of the engine oil pressure regulating device of the present invention. Depend on figure 1 and figure 2 It can be seen from the combination that the engine oil pressure regulating device includes the housing of the oil pump 1, the pressure regulating valve 2 and the safety valve 3, and the housings of the oil pump 1, the pressure regulating valve 2 and the safety valve 3 are integrally cast. Among them, the oil pump 1 can be divided into a rotor chamber and a non-rotor chamber. After the rotor is installed, it can be divided into three chambers, namely, the low-pressure chamber 4, the rotor chamber high-pressure chamber 5 and the non-rotor chamber high-pressure chamber 6; the oil inlet of the oil pump 1 The port is provided on the side wall of the low-pressure chamber 4.

[0023] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com