Direct type backlight module

A backlight module, direct type technology, applied in optics, nonlinear optics, lighting devices, etc., can solve problems such as increased power consumption, weak lamp tubes, and increased cost, reducing light intensity loss, reducing heat generation, and reducing effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical means and effects used by the present invention to achieve the purpose will be described below with reference to the accompanying drawings, and the embodiments listed in the following drawings are only for auxiliary illustration, and the technical means of this case are not limited to the listed drawings.

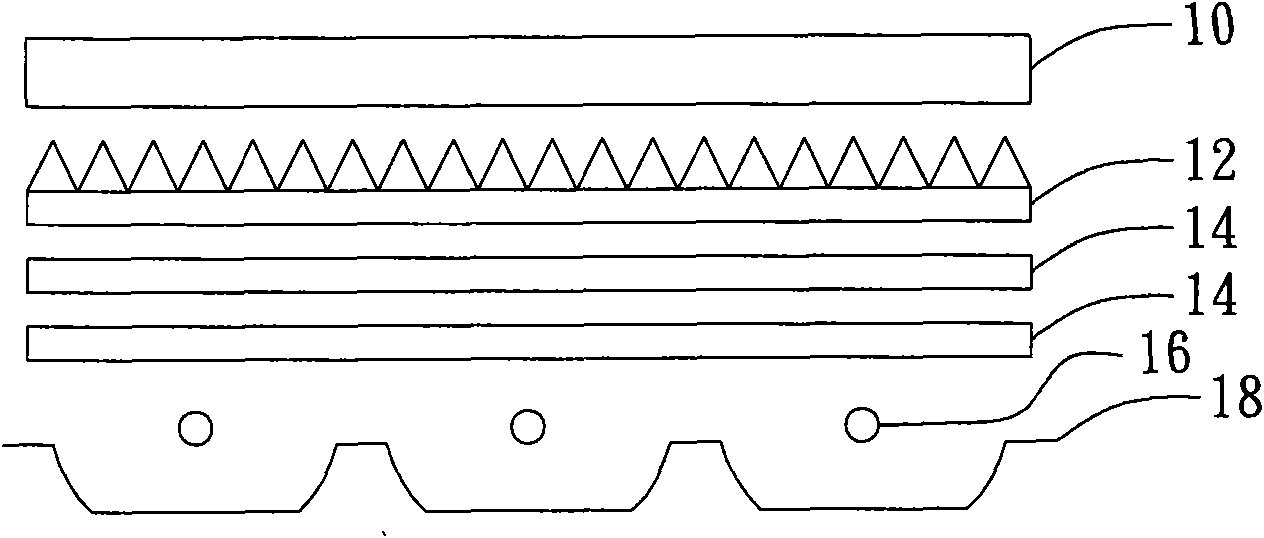

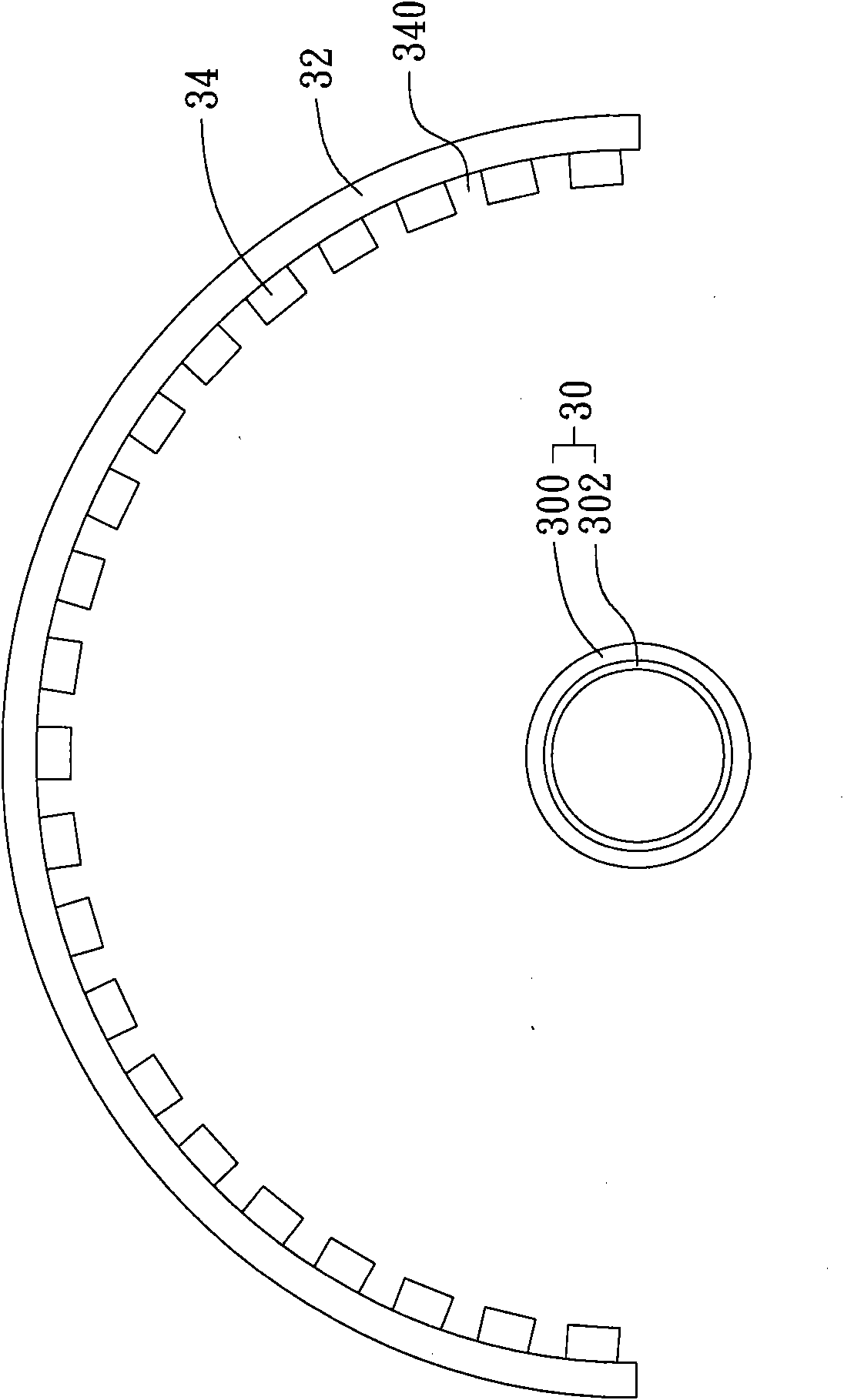

[0029] See image 3 , which is a sectional view of the direct type backlight module of the present invention, which shows the structure of the light emitting part and the partial reflection layer. Wherein the direct-type backlight module includes a first reflective layer 34 coated on a plurality of shells 32, and a plurality of light-transmitting regions 340 are arranged on the first reflective layer 34; the light-emitting part 30 is a general white light source, For example, white light cold cathode tube (CCFL), or it can be a whole row of light-emitting diodes and its front and rear positions can be adjusted or mixed use of light-emitting diodes and l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com