Current-equalizing pneumatic heat exchanging bed

A technology of dynamic exchange and heating surface, applied in fluidized bed combustion equipment, lighting and heating equipment, combustion type, etc., can solve the problems of large maintenance workload, long response time, small maintenance space, etc., and achieve manufacturing and maintenance operation costs. The effect of small size, short operating response time and long service life of the tube bundle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

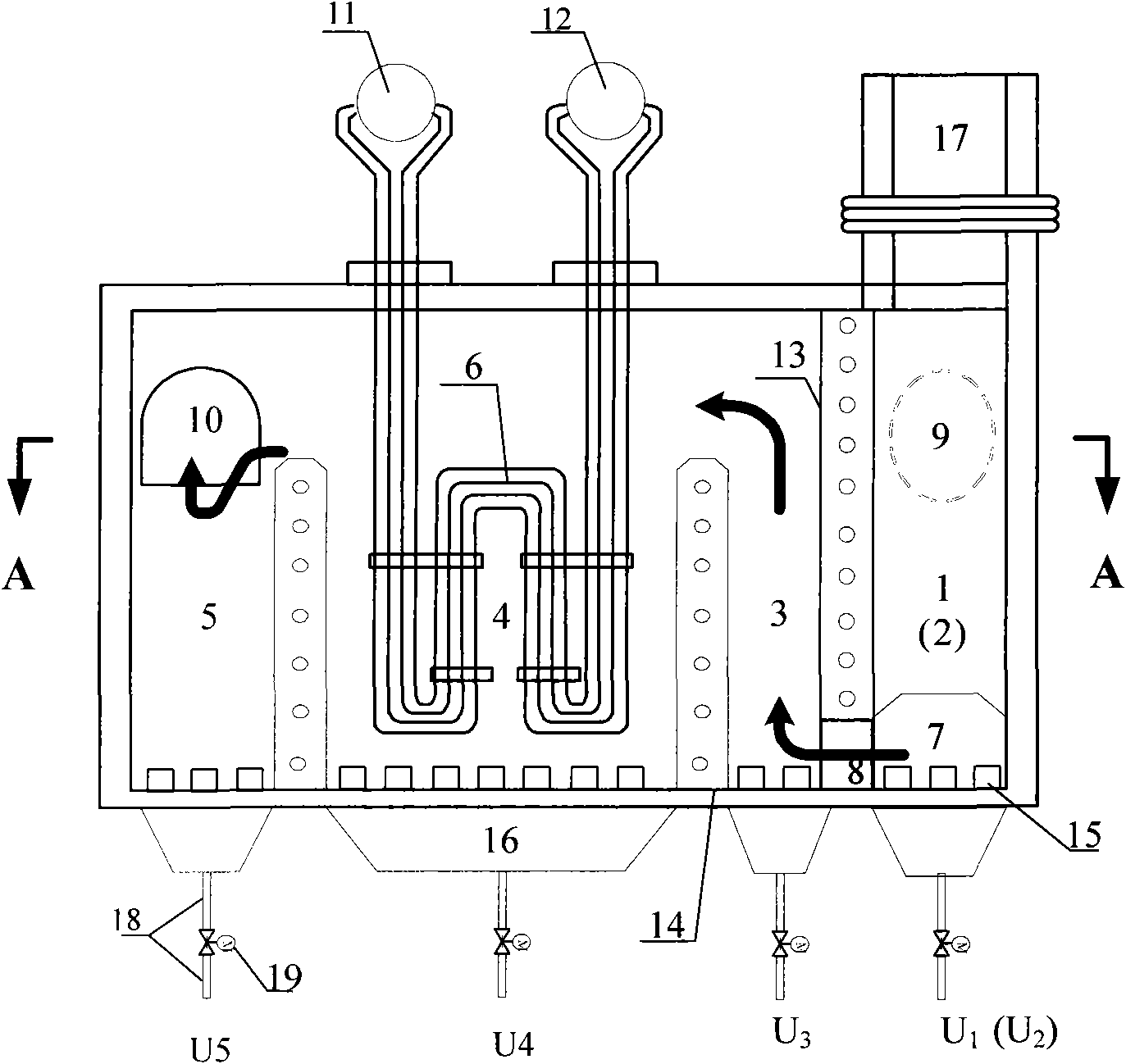

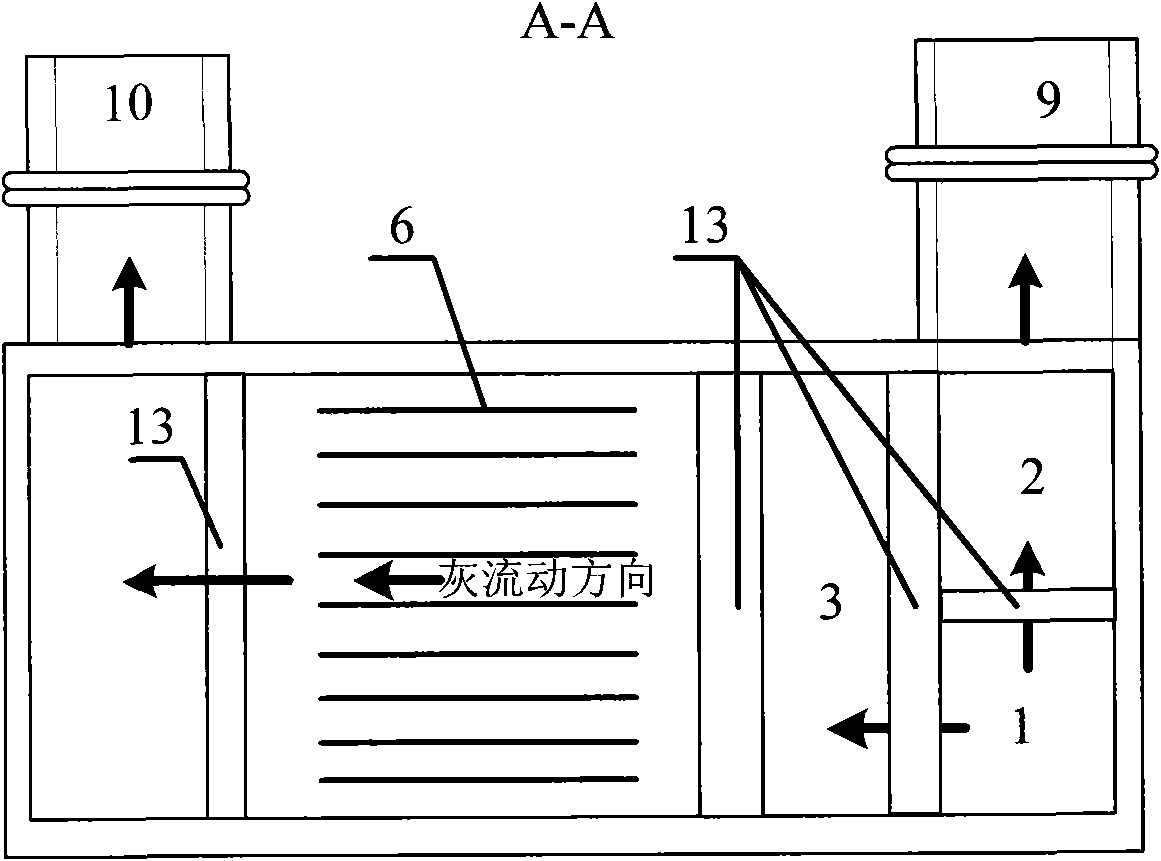

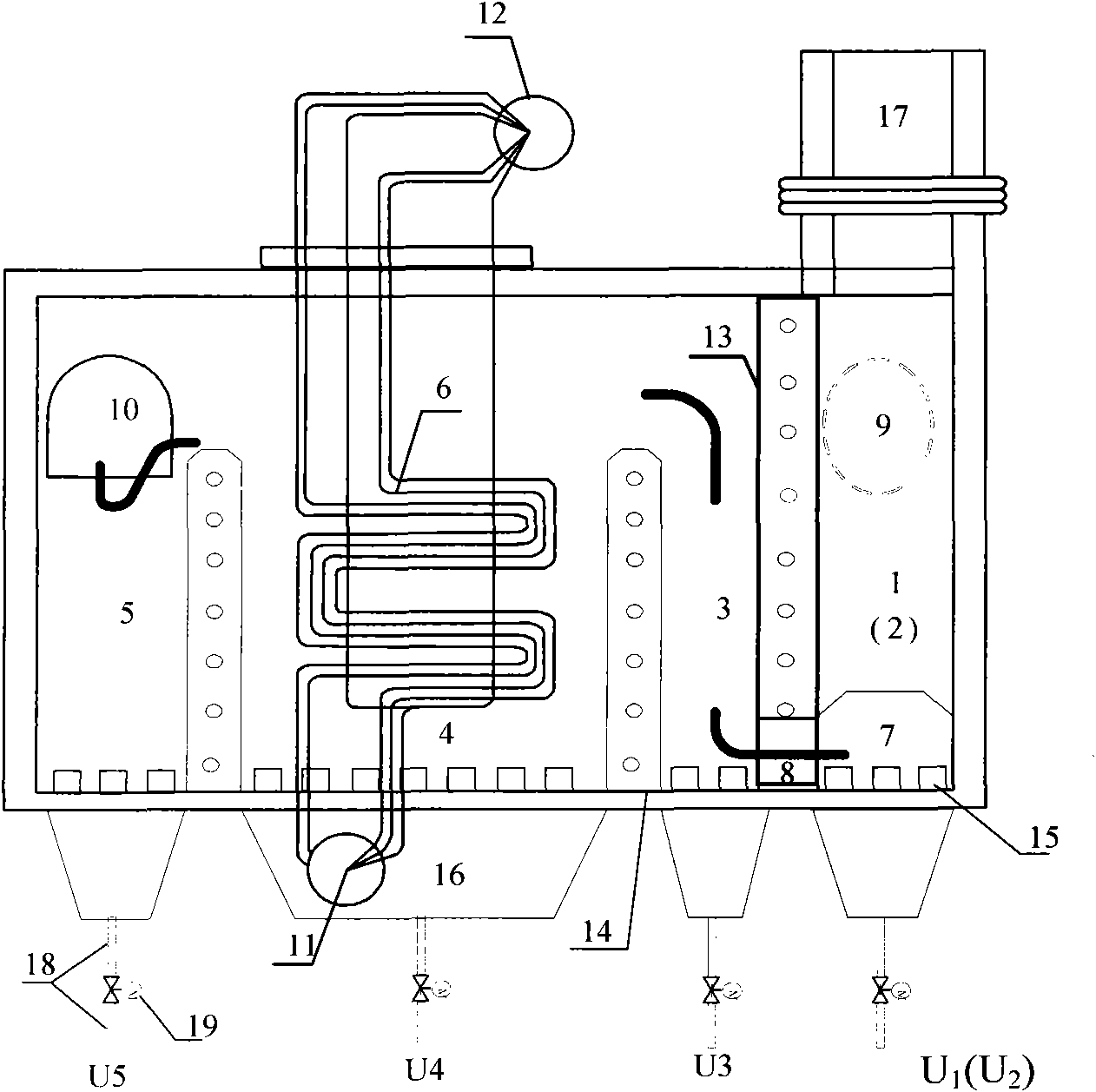

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0023] Such as figure 1 , 2 , 3, 4, and 5, the heat exchange bed of the present invention is composed of a feed bin 1, a high temperature bin 2, an equal flow bin 3, a heat exchange bin 4, and a low temperature bin 5, with Water-cooled partition wall13. The water-cooled partition wall 13 is composed of pipe rows arranged in parallel, cooling water is passed through the pipes, and the wear-resistant refractory material fixed on the outer surface of the pipes is laid on the outer wall. The lower part of the water-cooled partition wall 13 between the feed bin 1 and the high-temperature return bin 2 is provided with a particle flow port 7, and the lower part of the water-cooled partition wall 13 between the feed bin 1 and the flow equalization bin 3 is provided with a particle flow port 8. The particle flow port 8 can also be located at the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com