Method for measuring inside and outside outline as well as wall thickness of differential confocal targeting trigger-type hollow sphere and device therefor

A differential confocal, hollow sphere technology, used in measuring devices, optical devices, instruments, etc., to achieve the effect of improving lateral resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

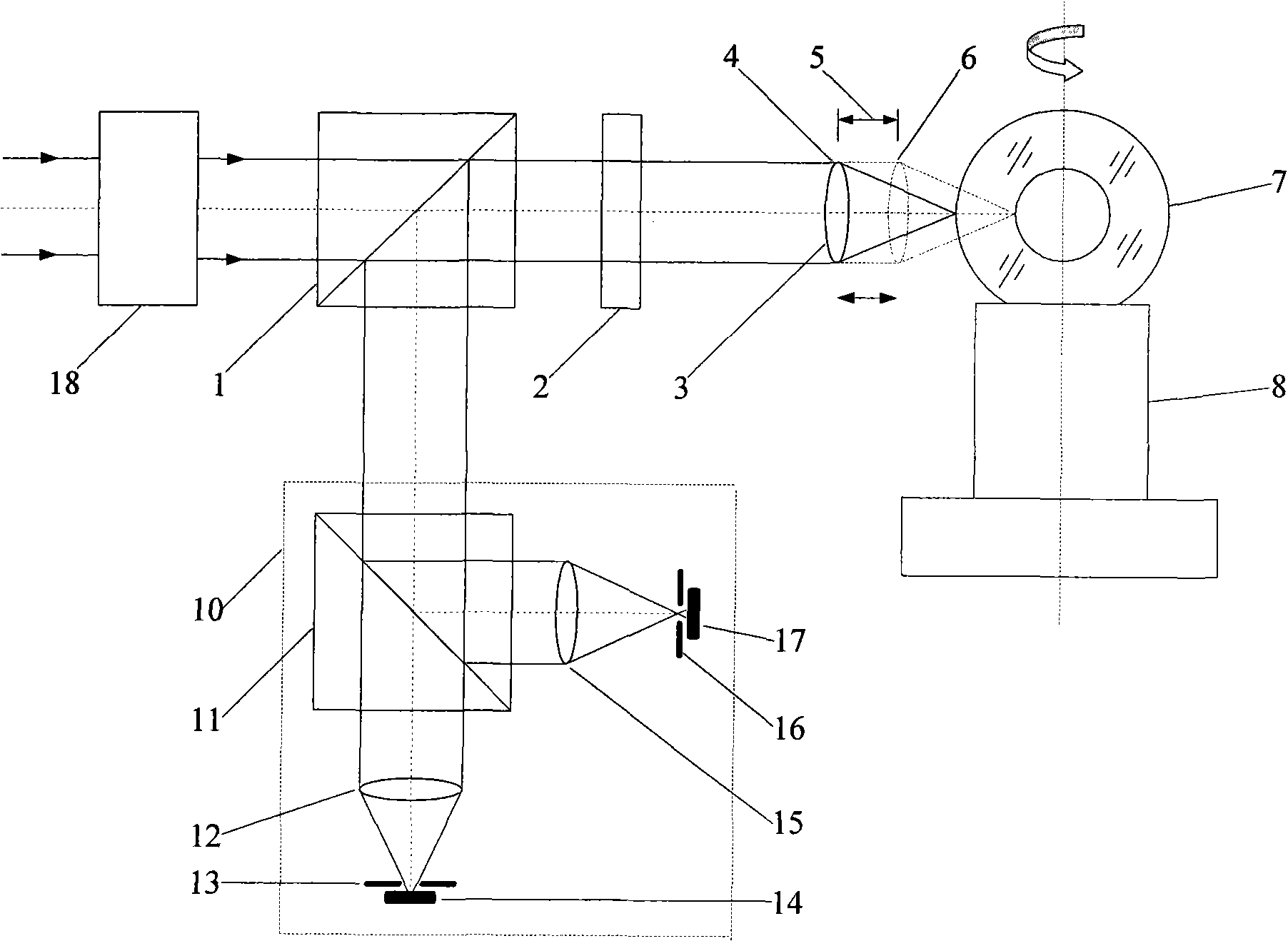

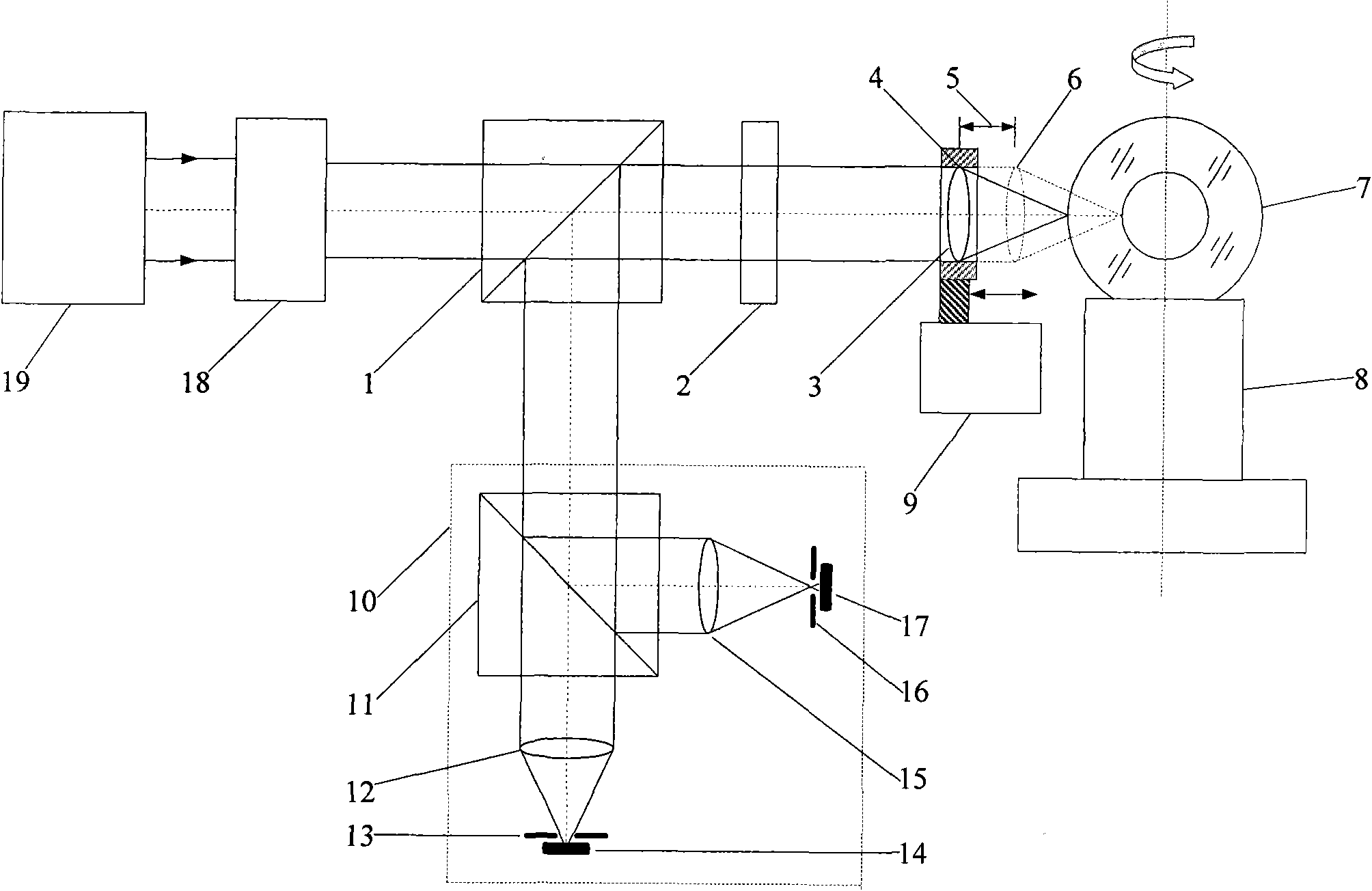

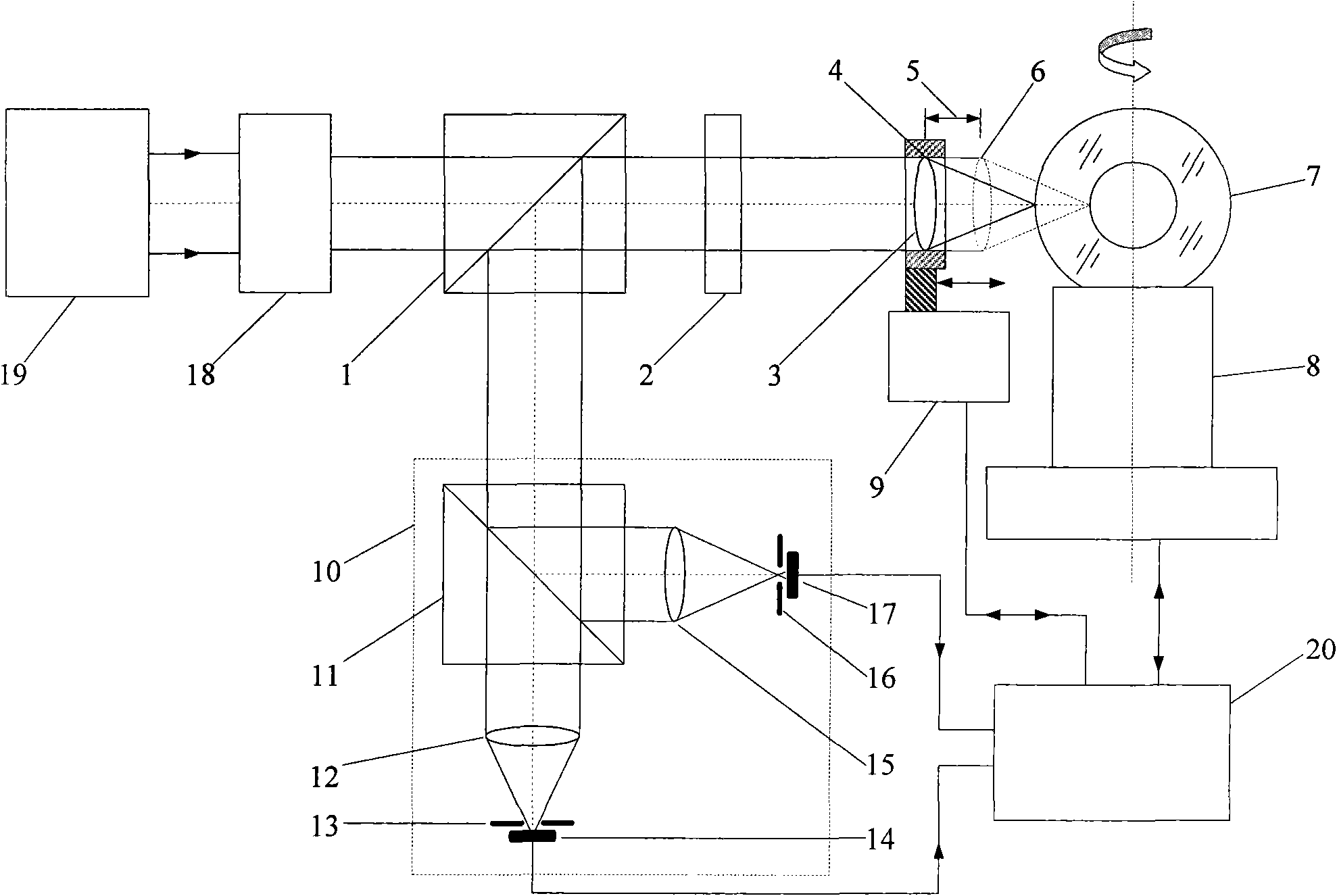

[0040] Such as image 3 As shown, a method for differential confocal aiming trigger microsphere inner and outer surface profile measurement, the measurement steps are:

[0041] At first, turn on light source 19, emit parallel light and pass through the spectroscopic system that is made of polarization beam splitter 1 and 1 / 4 wave plate 2, converge on the surface of hollow microsphere 7 through lens 3, light is reflected by the surface of hollow microsphere 7 again Finally, it is reflected by the 1 / 4 wave plate 2 and the polarizing beam splitter 1 into the beam splitter 11 in the differential confocal collimation system 10; 14, the reflected light passes through the lens 15 and the pinhole 16 to the detector 17; the objective lens 3 is driven to scan reciprocally in the direction of the optical axis by a PI nanoscale piezoelectric ceramic displacement driver (P-725). The response curve of the differential confocal aiming system 10 is as follows Figure 4 shown. By detecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com