Manufacturing method of touch screen module

A manufacturing method and touch screen technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of increasing production time and cost, improve production efficiency and product yield, reduce air bubbles, vacuum The effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In the traditional process of manufacturing touch screen modules, the vacuum degree is improved during vacuuming, which saves the process of rolling the roller, and improves the productivity while maintaining a high product yield.

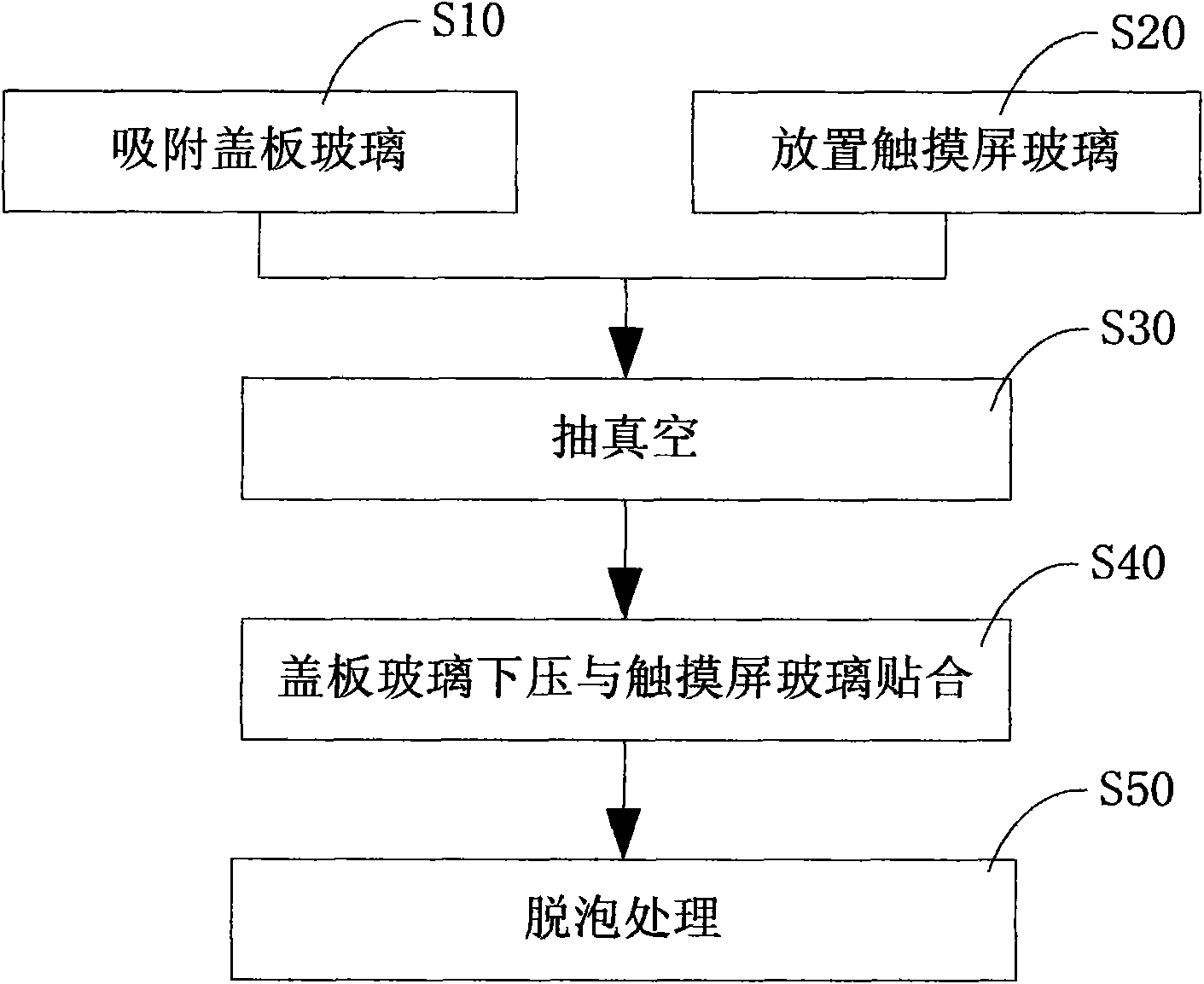

[0014] Such as figure 1 As shown, it is a flow chart of making a touch screen module in this embodiment. include:

[0015] Step S10: Adsorbing the cover glass. The cover glass is the external protective part of the touch screen, which requires certain strength, scratch resistance and light transmittance. The glass cover plate in this process is pre-cut to meet the required size specifications. Clean the surface, especially the side that is attached to the glass of the touch screen, free of debris. The glass cover is picked up by the suction device and kept horizontally placed, and then sent to the predetermined fitting position.

[0016] Step S20: Place the touch screen glass. The touch screen glass is a sensing part that senses extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com