Filter for electronic signals and method for manufacturing it

An electronic signal and filter technology, applied in waveguide-type devices, circuits, electrical components, etc., can solve problems such as insufficient meaning of control matching and coupling, lack of optimization, and inability to fully control the direction and distribution of the excitation electric field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In general, the features described in this specification are to be regarded as being combinable with each other to the extent technically possible, even if this is not explicitly stated. Like reference numerals will refer to like parts.

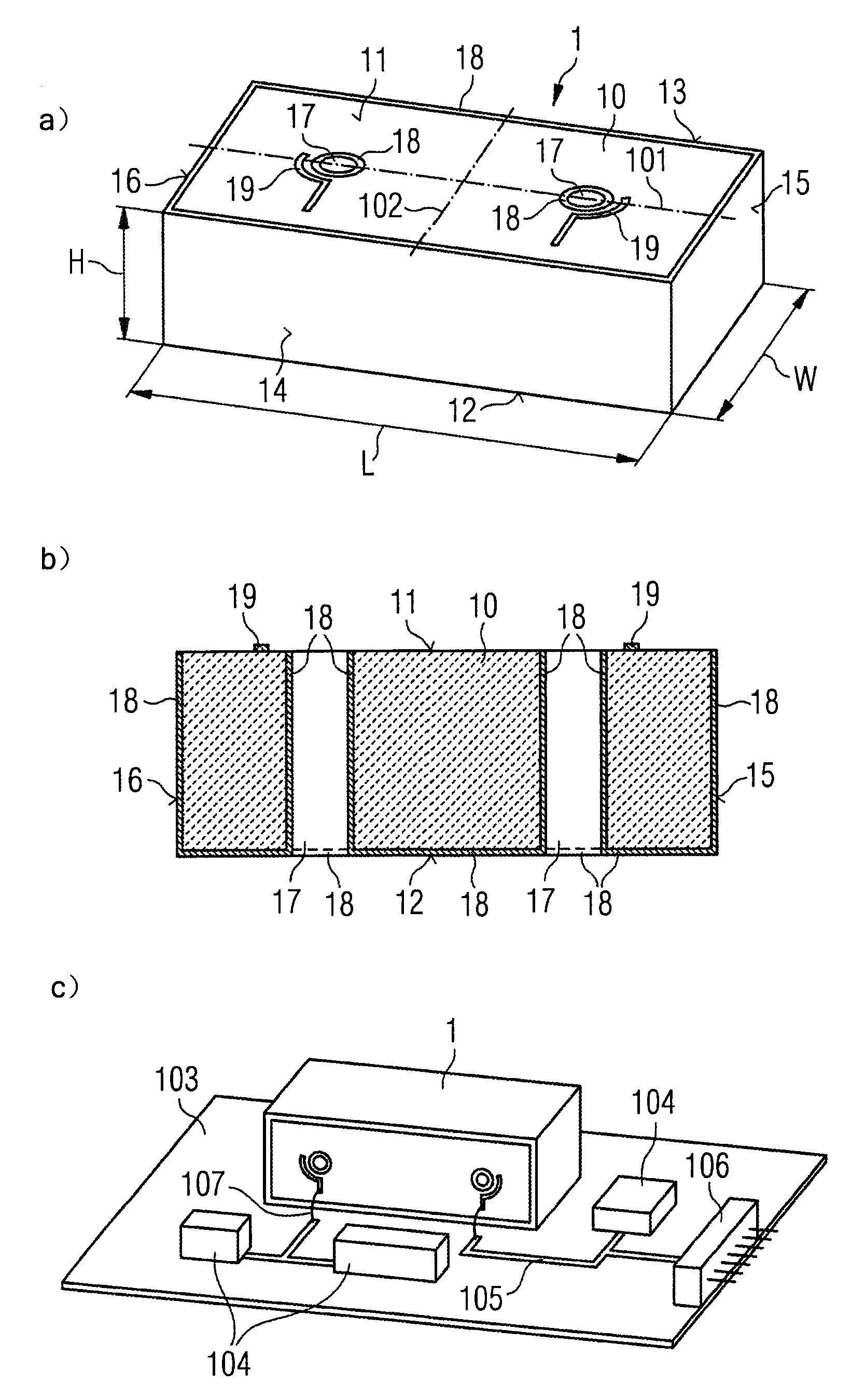

[0032] figure 2 A first embodiment of the invention is shown, showing a modified shape of the filter. The filter may be a ceramic monolithic filter as already stated. Unless otherwise stated below, the filter according to the present invention may have the same figure 1 Characteristics described in a-1e.

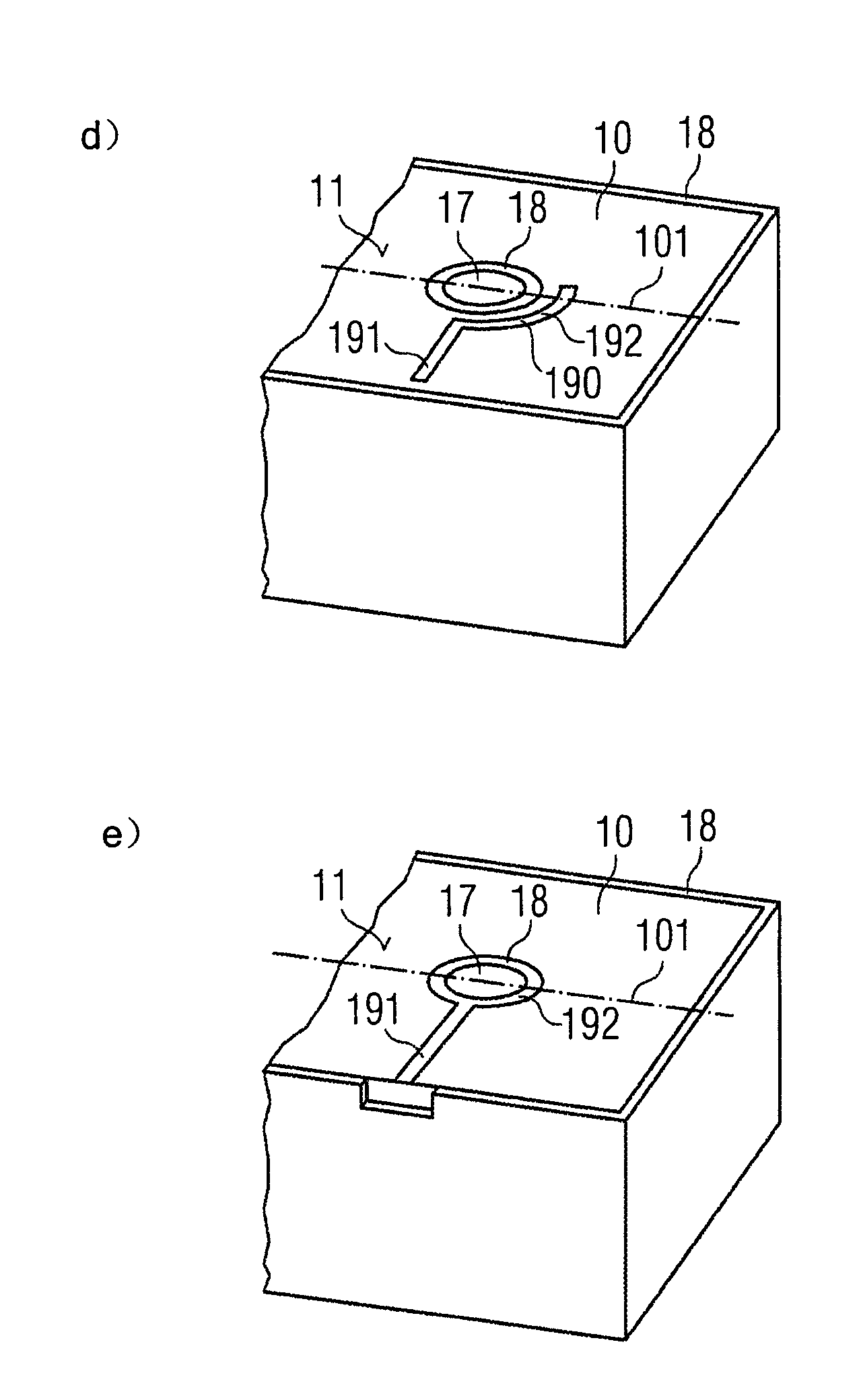

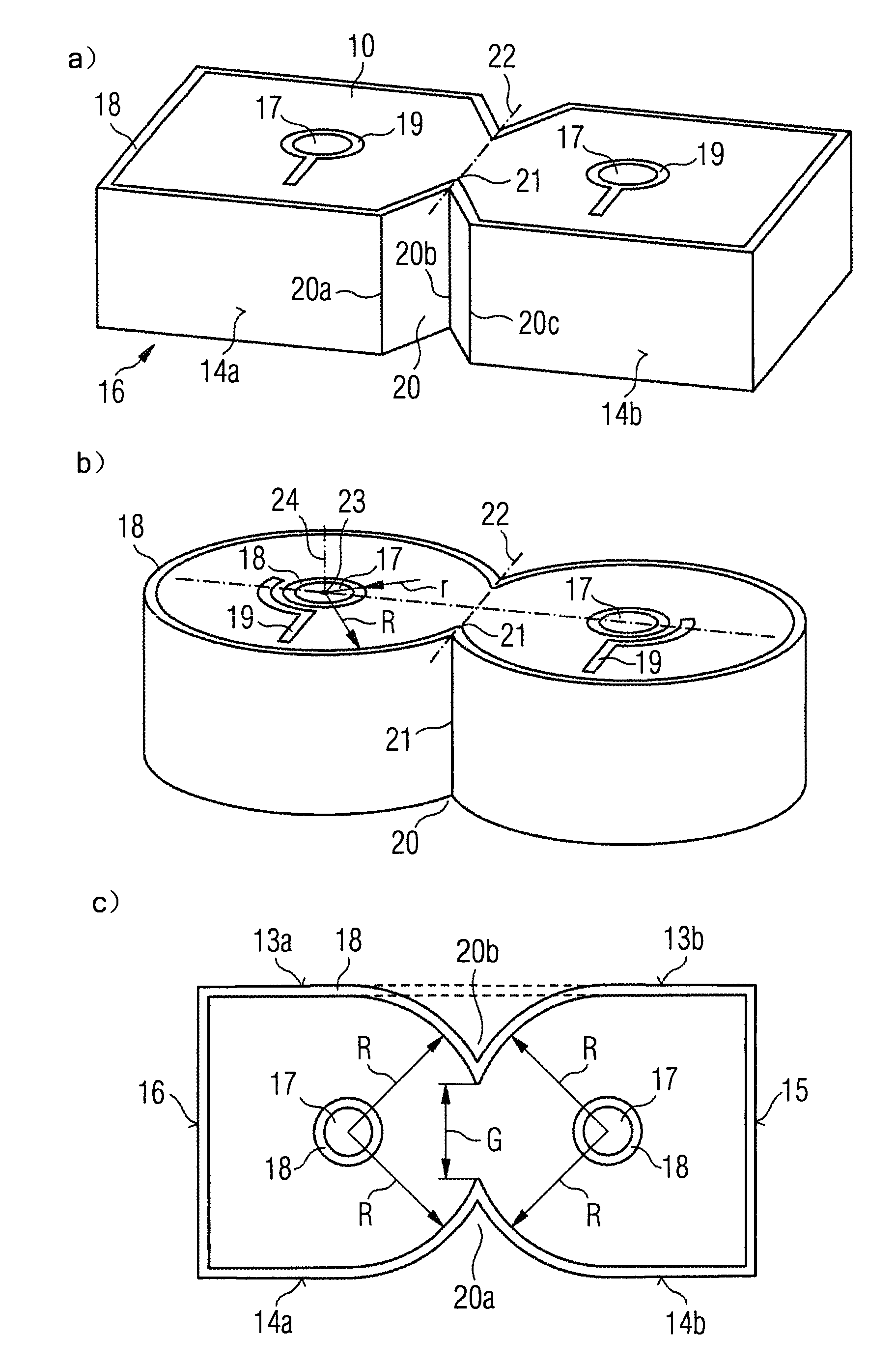

[0033] The body 10 of the filter 1 has a first surface 11 from which there are two holes 17, which may be resonator holes, which extend into the body, preferably perpendicular to the first surface 11, and preferably through the entire Body to second surface 12 (not visible). a surface of the body 10, namely figure 2 A fourth surface 14 in the body, from which the hole does not extend, has a recess 20 protruding into the body,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com