Microfluidic device

A technology of microfluidic device and microfluidic cavity, which can be used in measurement devices, fluid controllers, fluid mixers, etc., and can solve problems such as complex structures and complex manufacturing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

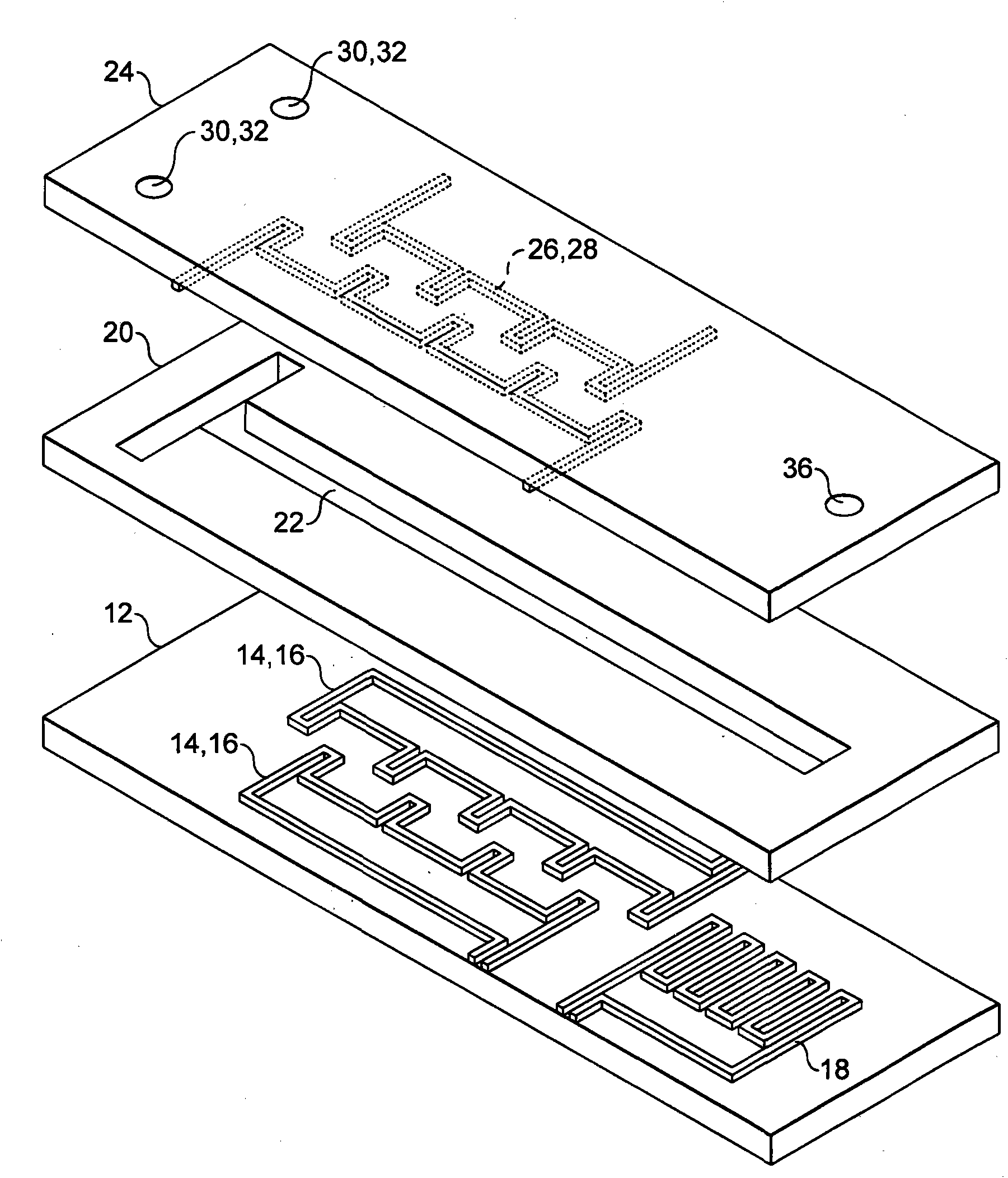

[0149] like figure 1 As shown, the micromixer 10 includes: a base layer 12 formed of glass with three serpentine conductors 14, 16, 18 embedded therein; the middle layer 12 ; and the upper layer 24 formed of glass with two further serpentine conductors 26 , 28 , two inlets 30 , 32 and an outlet 36 embedded therein.

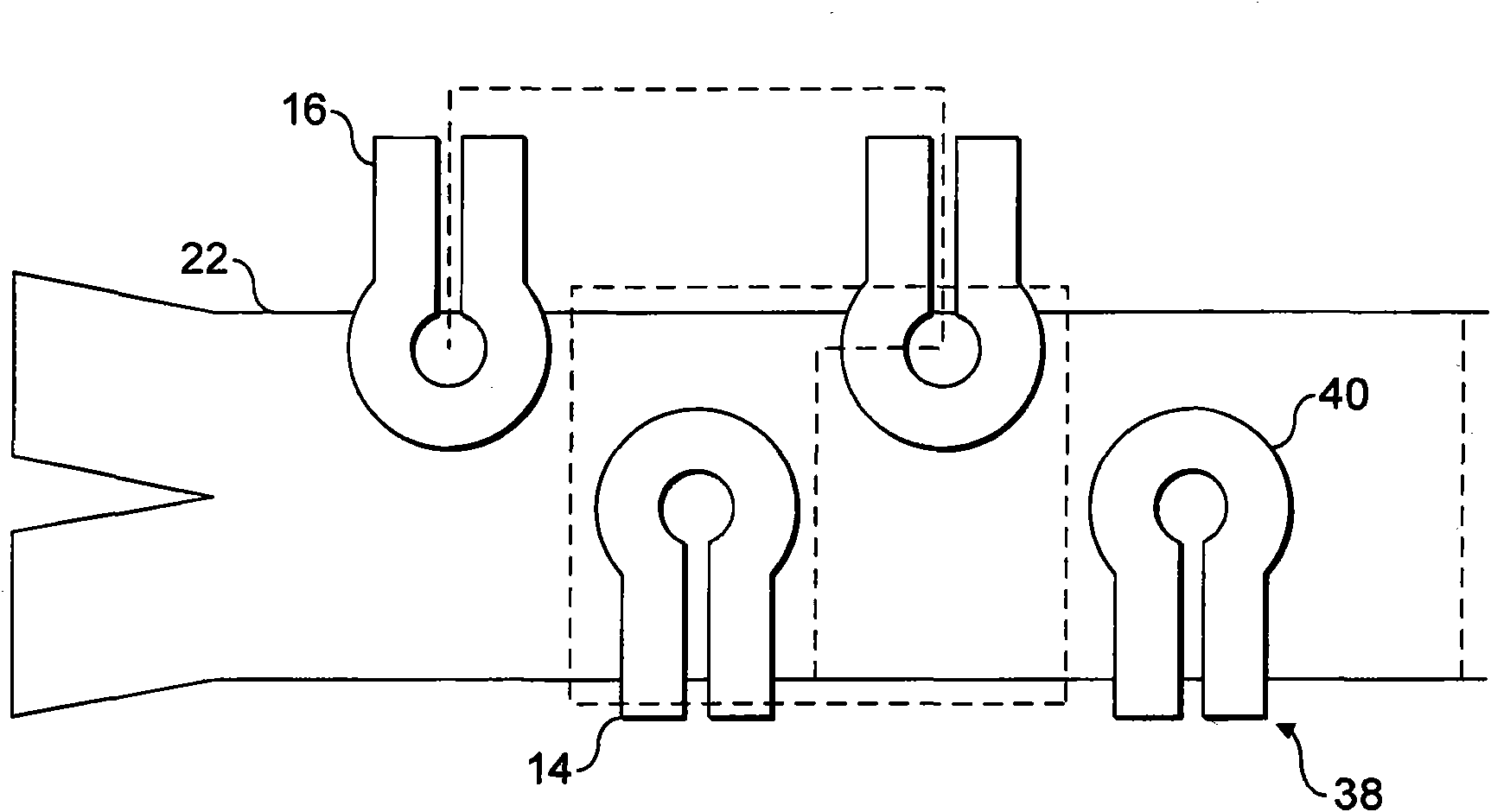

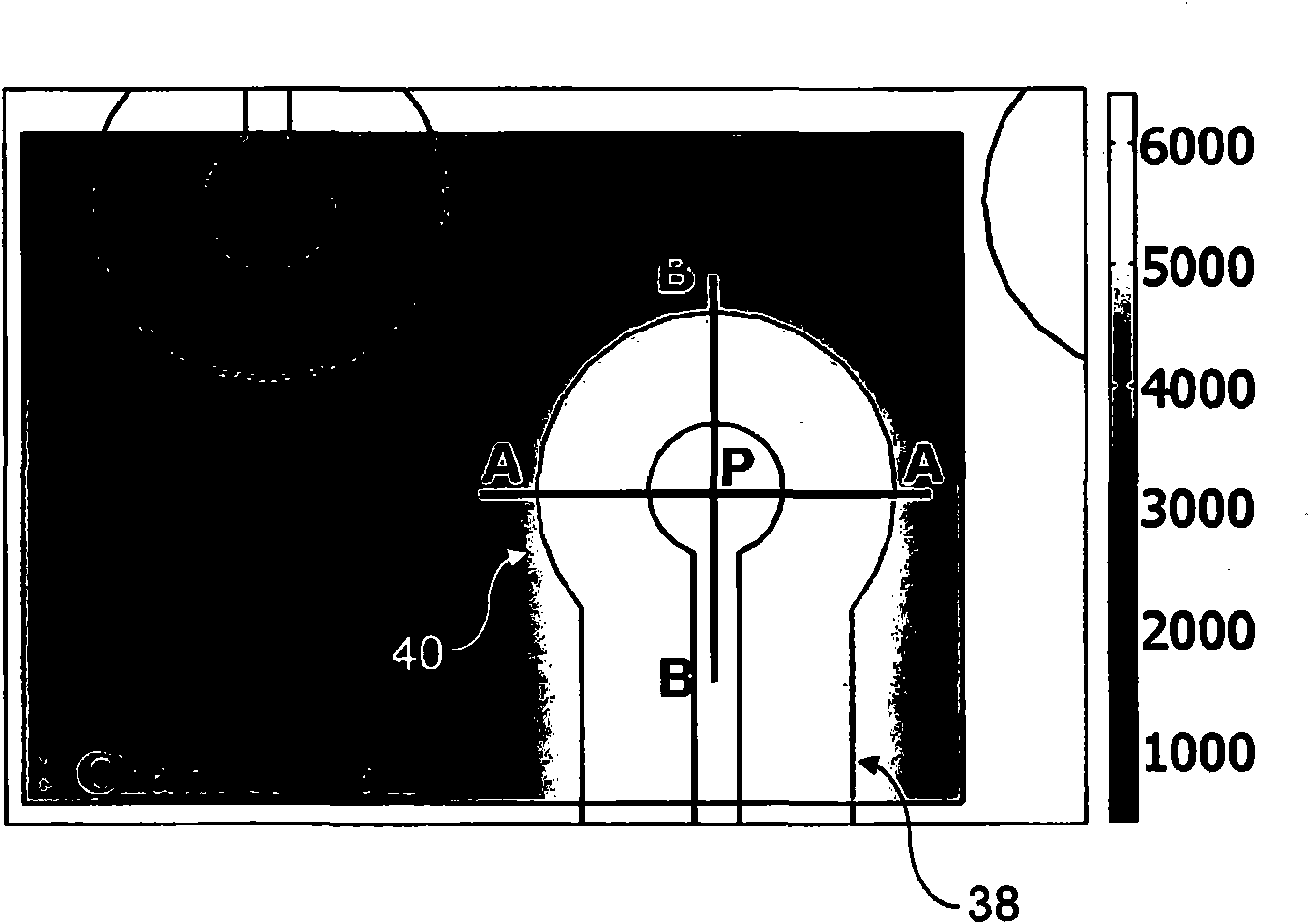

[0150] An example of the size of the device is in the figure 2 is shown in , which illustrates a top view of one mixing cell with boundaries. Each mixing unit includes two adjacent teeth from each conductor. Channel 22 is 150 μm (micrometer) wide and 50 μm deep. The conductors 14, 16 are in the shape of teeth 38 with rounded tips 40 and are 35 μm high and 35 μm wide in cross-section, and the distance between the centers of the rounded tips 40 of the conductors is 100 μm and 65 μm in the x-direction and y-direction respectively . Each row of upper and lower conductors 14, 16 is alternately connected to a power source. The mixing operation cycle consists of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com