Water scavenging system

A water pipe, water blocking technology, applied in the direction of charging system, engine components, liquid fuel feeder, etc., can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

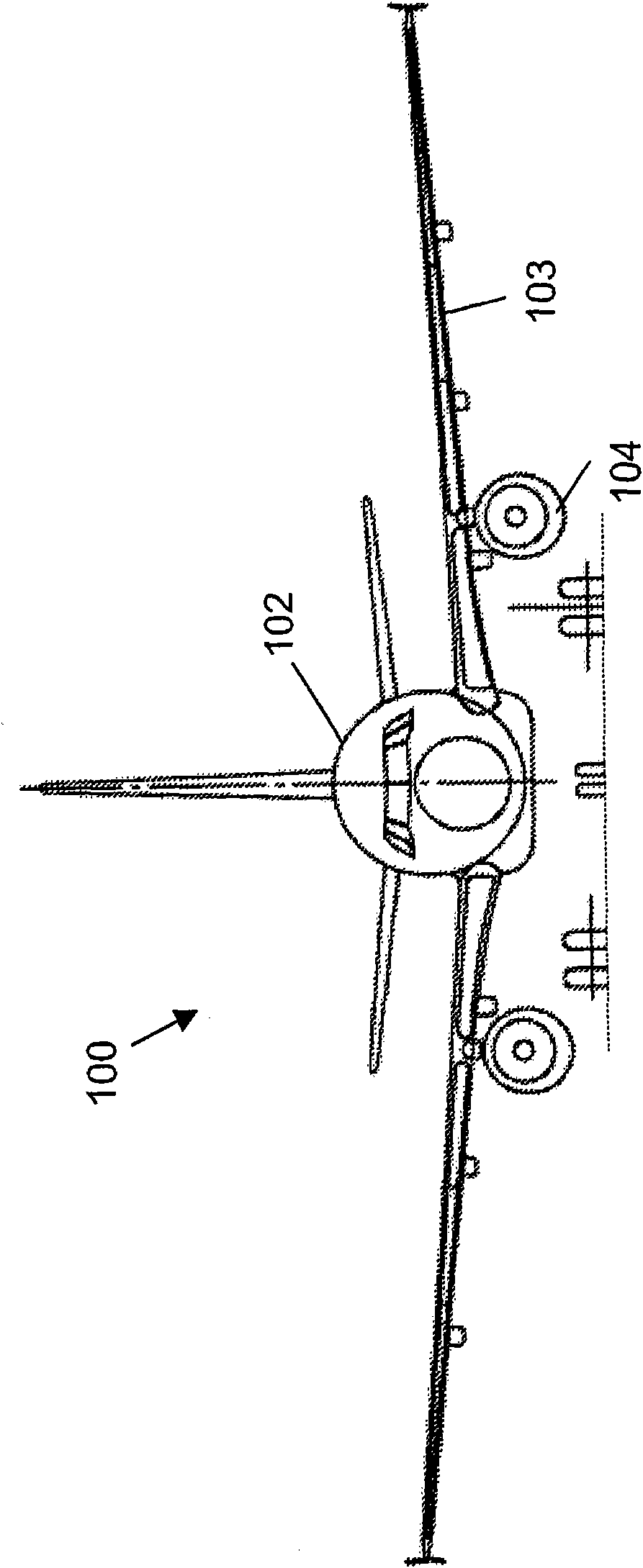

[0023] refer to figure 1 , the aircraft 100 includes a fuselage 102 supporting a pair of wings, the left wing being designated 103 . Each wing carries an engine, figure 1 The engine on the middle left hand side is marked 104. Fuel for each engine is stored in the center tank and one or more wing tanks.

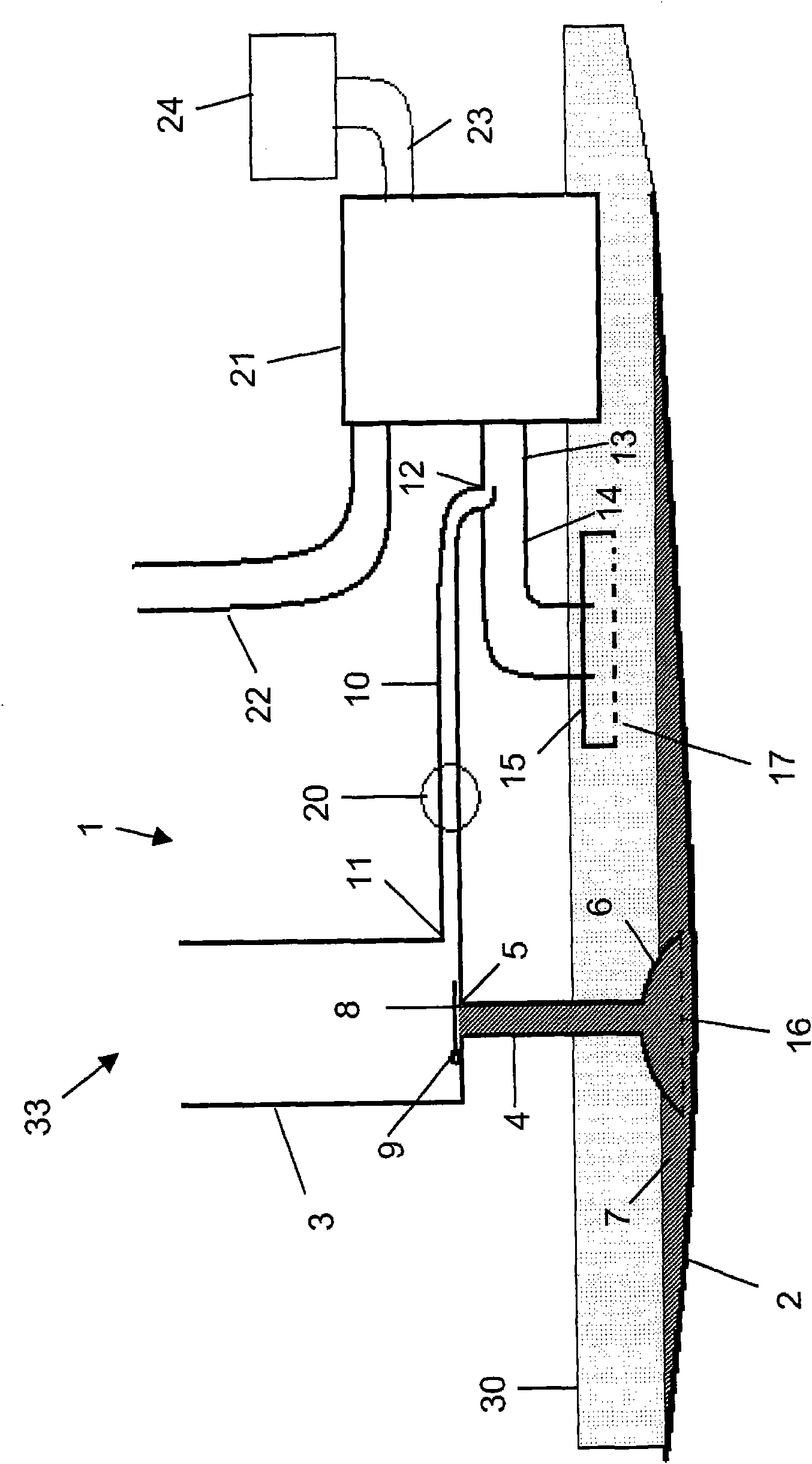

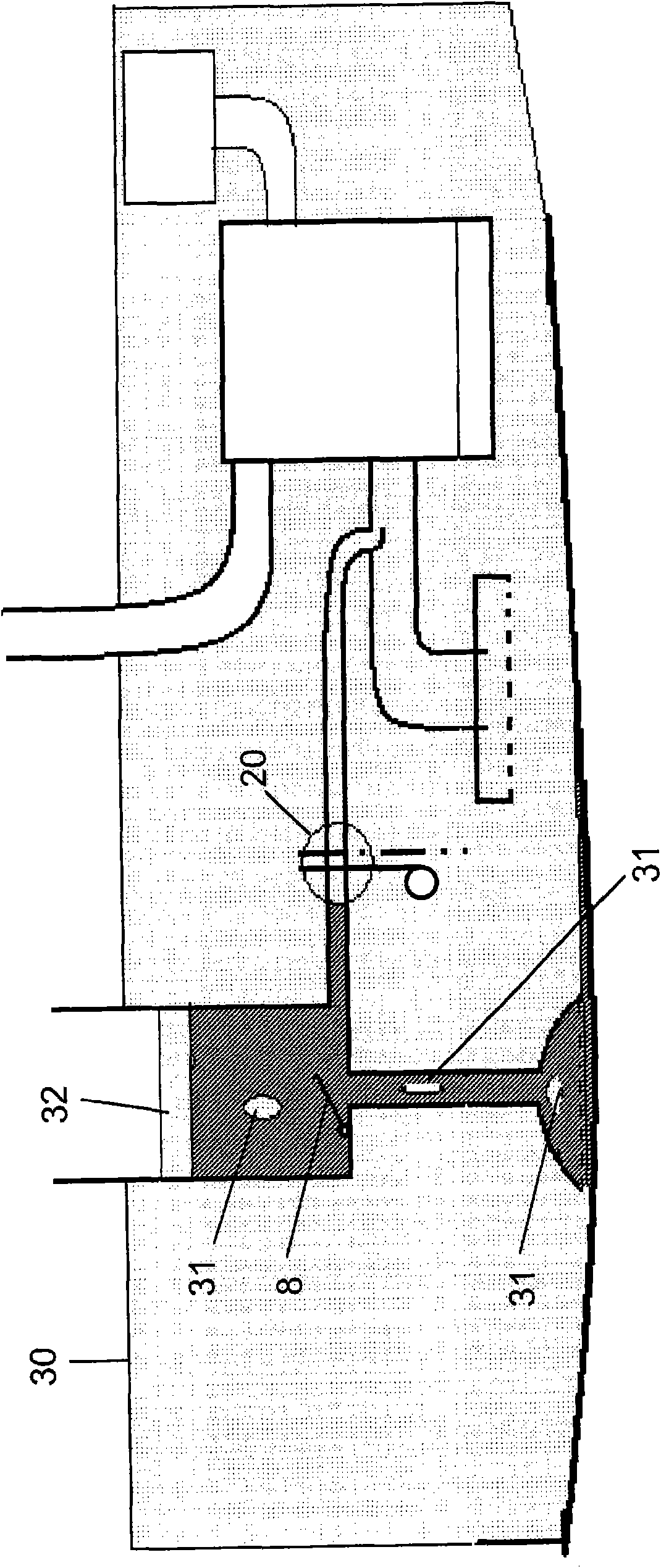

[0024] figure 2 A water removal system is shown in , which is installed in a wing tank 2 . The water removal system comprises a water tank 3 and a water removal pipe 4 having an outlet 5 in the bottom of the water tank 3 and an inlet 6 immersed in pool water 7 at the bottom of the fuel tank 2 . The water tank 3 is usually a vertical pipe with a diameter of 60 mm, a length of 0.4 m and an opening at the top.

[0025] One-way valve 8 is installed on the water tank, and is installed on the pivot 9, in figure 2 The one-way valve 8 is shown in the closed position, and the one-way valve 8 closes the outlet 5 of the water removal pipe 4 in the closed position. It should be u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com