Continuous disk centrifugal ore separator

A disc-type centrifuge and concentrator technology, applied in the field of ore processing, can solve the problems of incomplete recovery, small processing capacity, complex structure, etc., and achieve the effects of reducing post-processing capacity, increasing concentration, and simple electrical control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

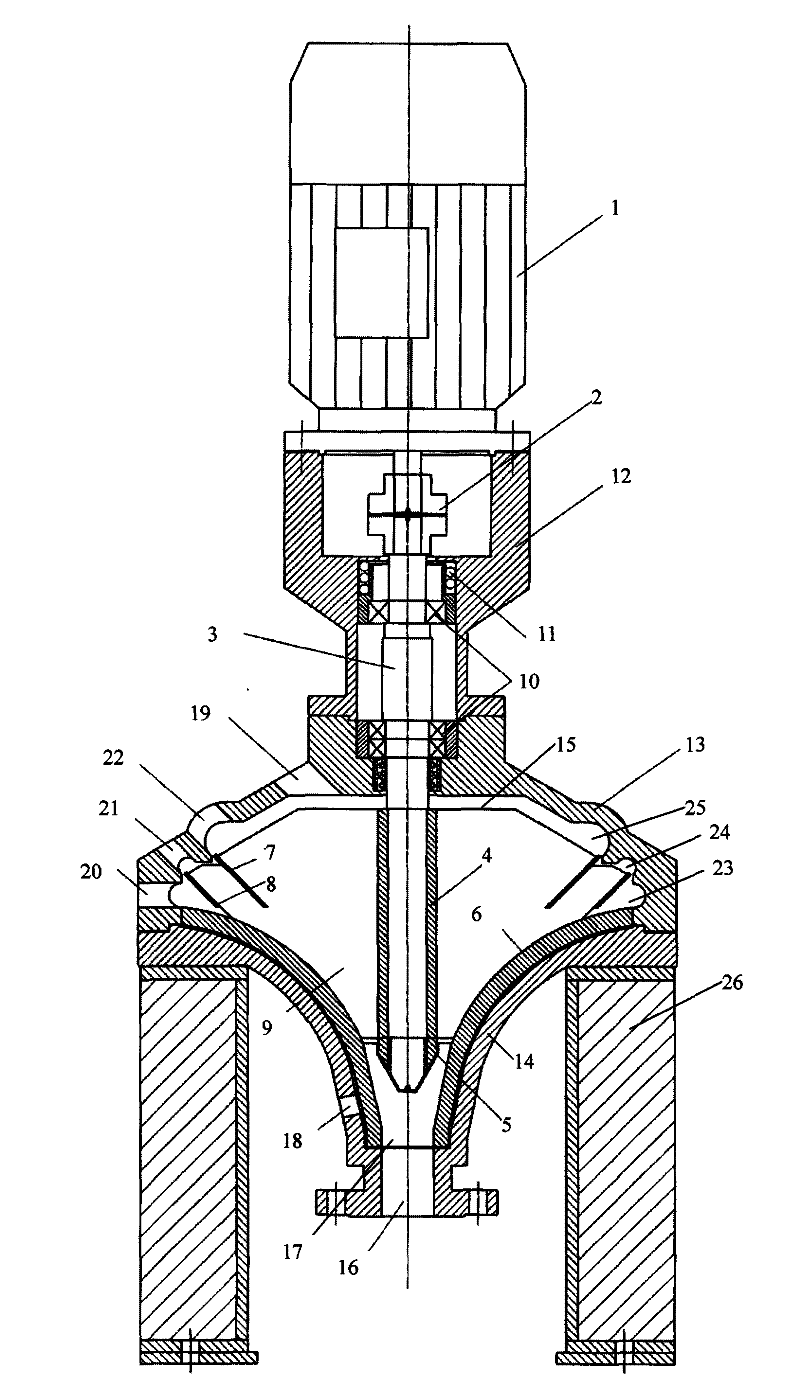

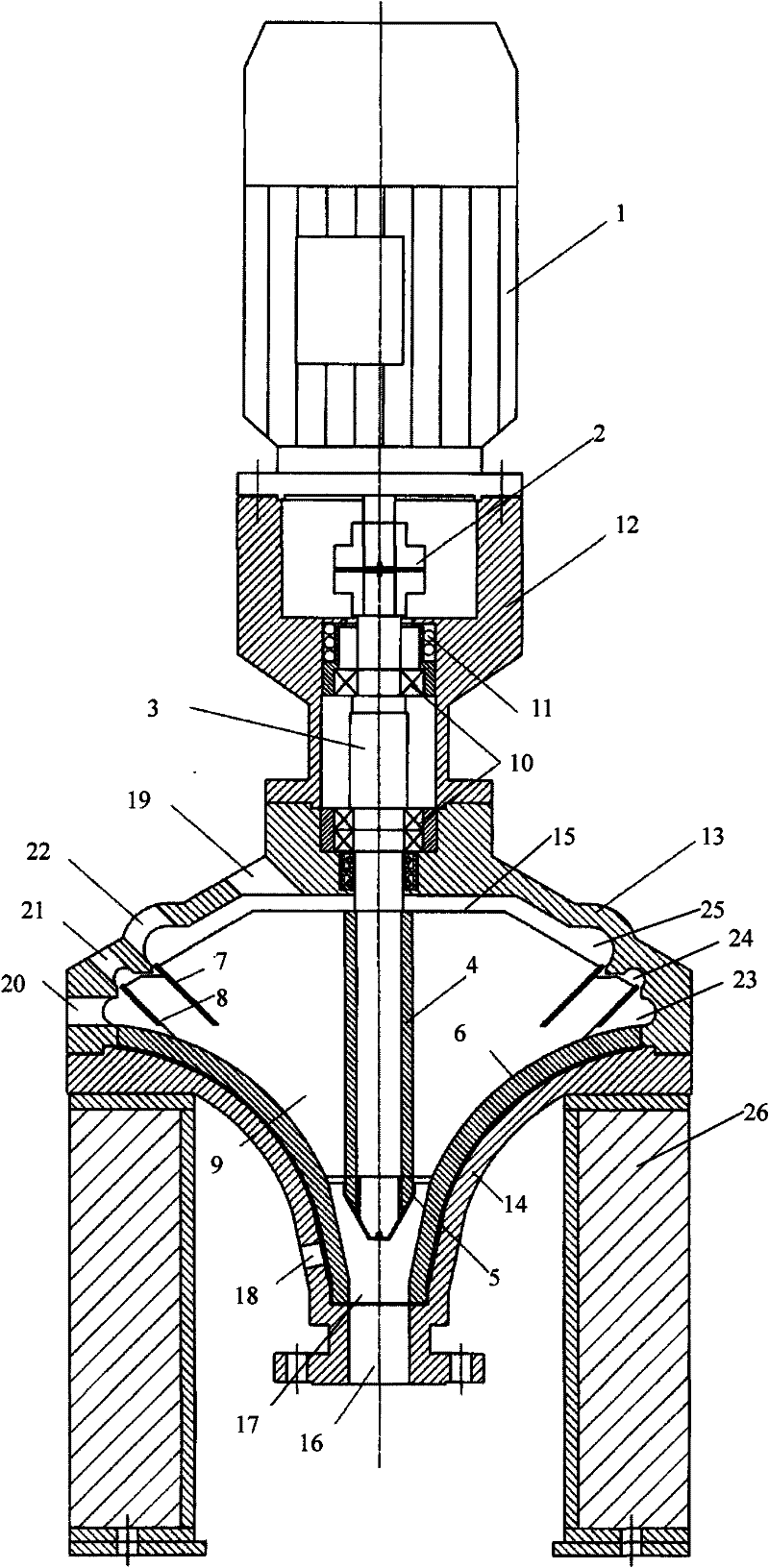

[0018] As shown in the figure, the present invention discloses a continuous disc centrifugal concentrator, which includes a motor 1 vertically arranged from top to bottom, a motor base 12 connected to the motor, and a centrifuge cover connected to the motor base with a mineral outlet 13 and the centrifuge base 14 whose section is connected with the centrifuge cover is a parabolic shape; the center of the motor base and the centrifuge cover is provided with a vertical shaft hole, and a main shaft 3 connected with the motor output shaft passes through the motor base The shaft hole of the centrifuge cover extends into the cavity 15 formed by the centrifuge cover 13 and the centrifuge base 14; the cavity 15 is provided with a parabola-shaped drum 6 nested on the main shaft 3 The shaft sleeve 4 and the connecting plate 9 connecting the shaft sleeve and the drum; the pulp inlet 16 is provided below the centrifuge base; the drum is in clearance fit with the centrifuge cover and the ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com