Ice-storage low-temperature pipe type air supply device

An air supply device and pipeline-type technology, which is applied in the field of pipeline-type air supply devices, can solve the problems of strong cold wind, low air supply temperature, power consumption, etc., and achieve the effect of simple manufacture, small space occupation and no cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

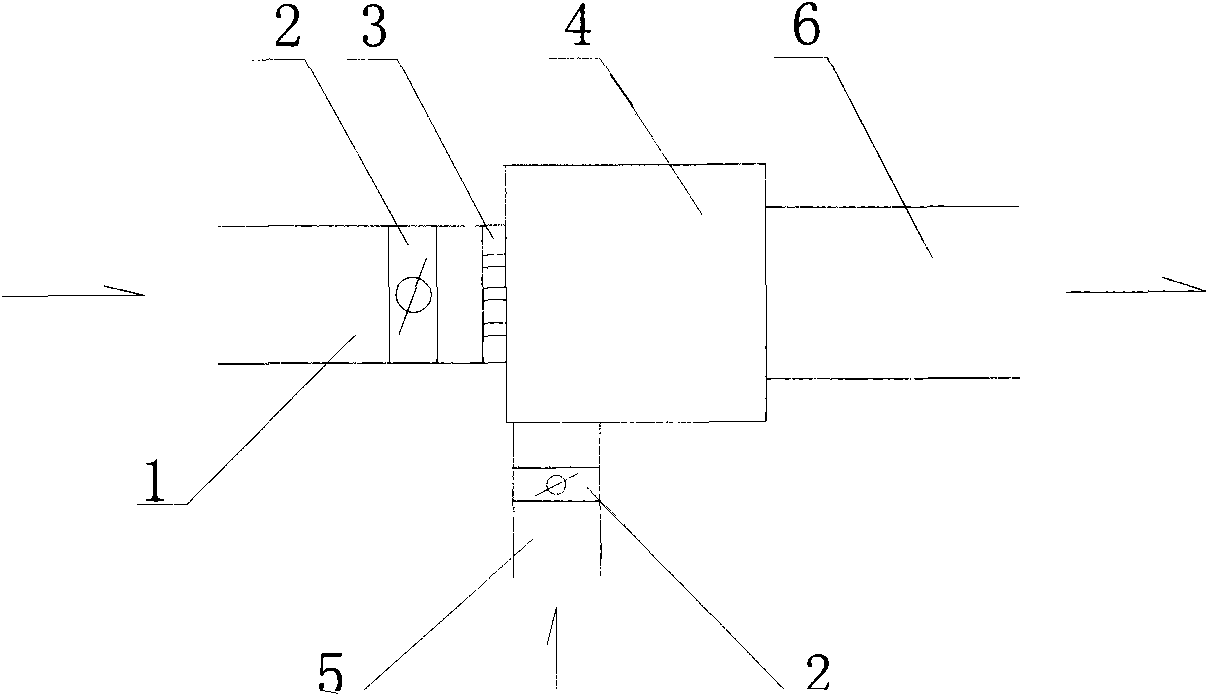

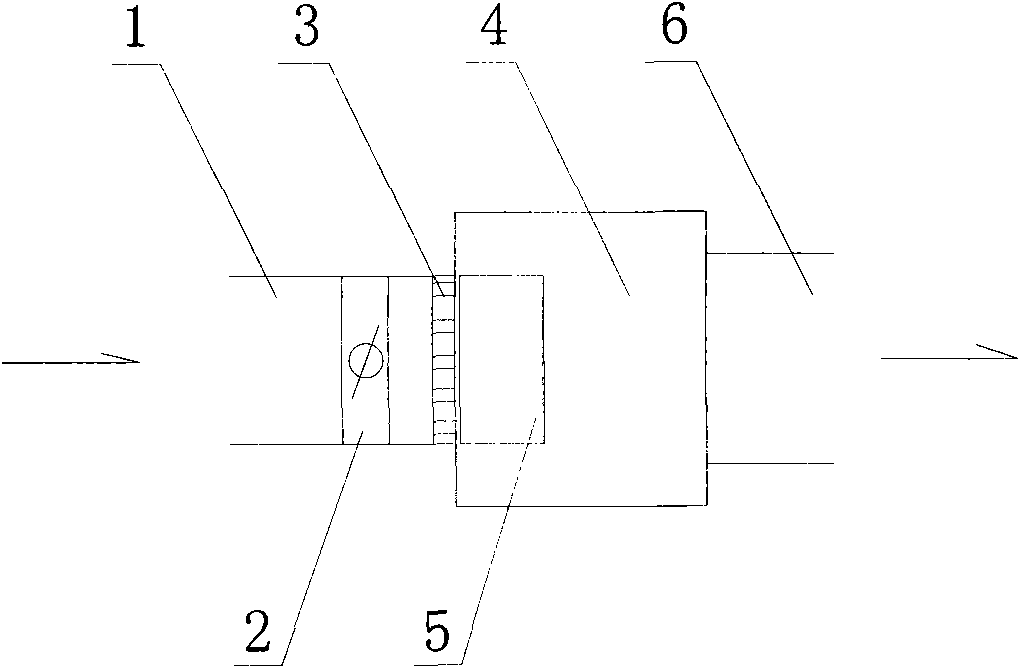

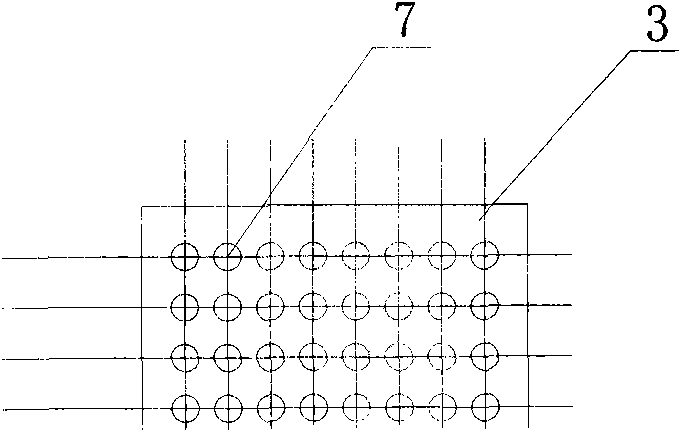

[0017] An ice-storage low-temperature pipeline air supply device, such as figure 1 shown. The primary air inlet pipe 1 is connected with a damper 2, the end of the primary air inlet pipe 1 is connected to the induced mixing box 4, the induced mixing box 4 is connected to the mixed air outlet pipe 6, and the primary air inlet pipe 1 is installed with An induction orifice 3, the side wall of the induction mixing box is provided with an induction tuyere, the induction air outlet is connected to the induction air duct 5, and the induction air duct is provided with a damper 2, and the arrangement of the holes 7 of the induction orifice is as follows: image 3 As shown, the holes are the same size and evenly distributed. In this embodiment, the induced tuyere is arranged at the bottom of the induced mixing box 1, such as figure 2 As shown, the position is close to the induction orifice plate 3. The ratio of the area of the induction orifice 3 to the cross-sectional area of t...

Embodiment 2

[0020] The difference from Example 1 is that there are two induced tuyeres in this embodiment, one is set at the bottom of the induced mixing box 1, and the other is set at the side wall of the induced mixing box 1 parallel to the air supply direction. The ratio of the area of the induction orifice 3 to the cross-sectional area of the primary air inlet duct 1 is 2:3. It satisfies the requirement of inducting indoor air into the induction mixing box, and after being mixed in the box, the mixed air at a suitable temperature is sent out from the mixed air outlet pipe 6, and the air-conditioning air enters the air supply port of the room without condensation and dripping.

Embodiment 3

[0022] The difference from Embodiment 1 and Embodiment 2 is that in this embodiment, there are two induced tuyeres, which are respectively arranged on the two side walls of the induced mixing box 1 parallel to the air supply direction. The ratio of the area of the induction orifice 3 to the cross-sectional area of the primary air inlet duct 1 is 1:2. It satisfies the requirement of inducting indoor air into the induction mixing box, and after being mixed in the box, the mixed air at a suitable temperature is sent out from the mixed air outlet pipe 6, and the air-conditioning air enters the air supply port of the room without condensation and dripping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com