Belt deviation detecting device for weighing and feeding machine

A detection device, feeder technology, applied in the direction of measuring devices, detailed information of weighing equipment, weighing equipment for continuous material flow, etc., can solve problems such as potential safety hazards, damage to the conveyor belt 4, and limited time for mediation operations , to achieve the effect of improving the utilization rate of equipment, improving work efficiency and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

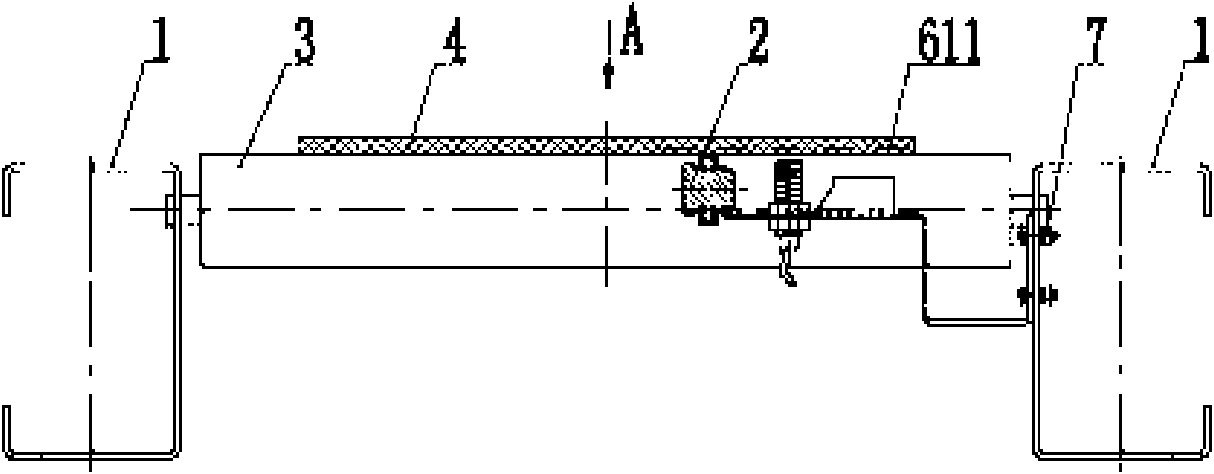

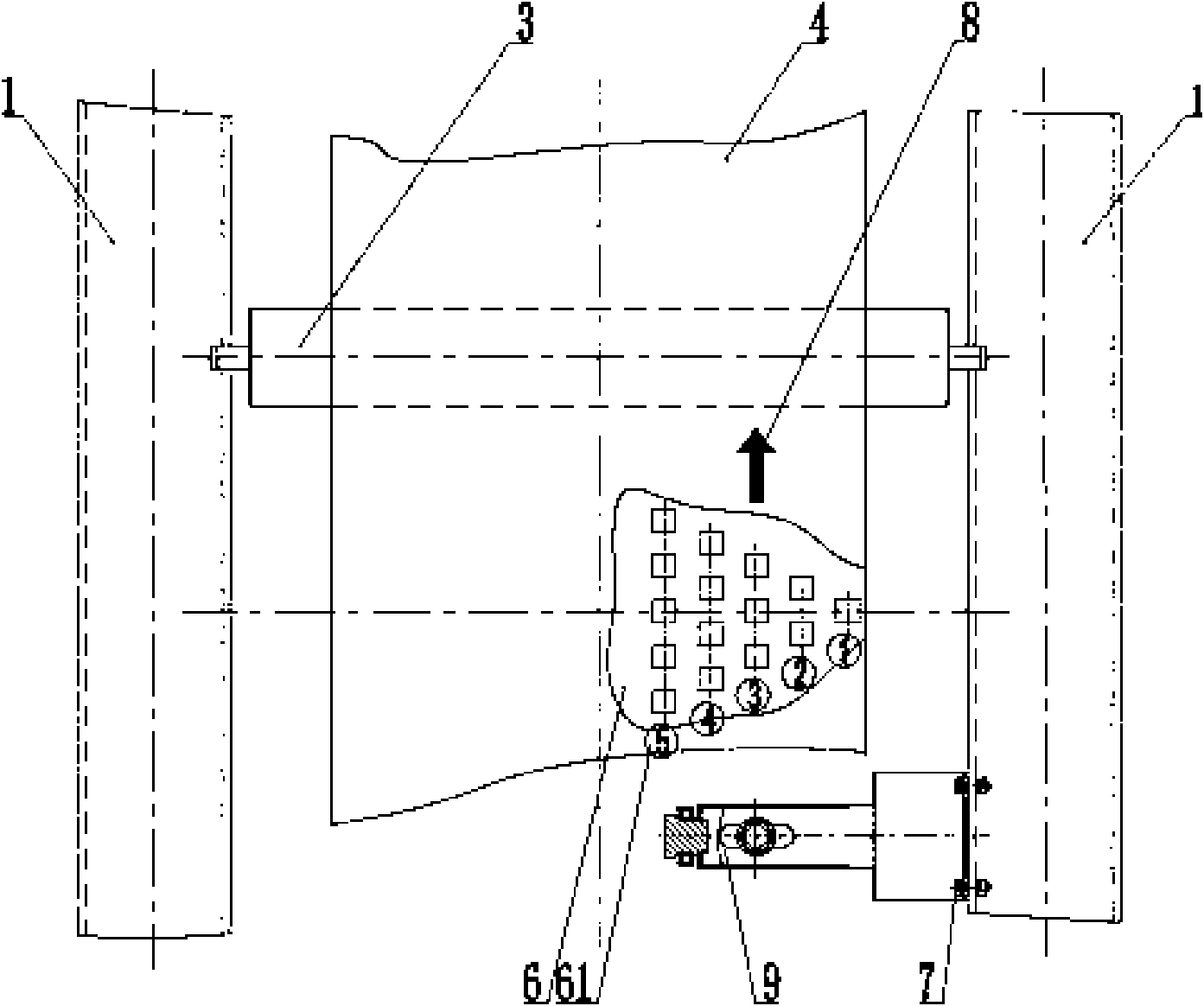

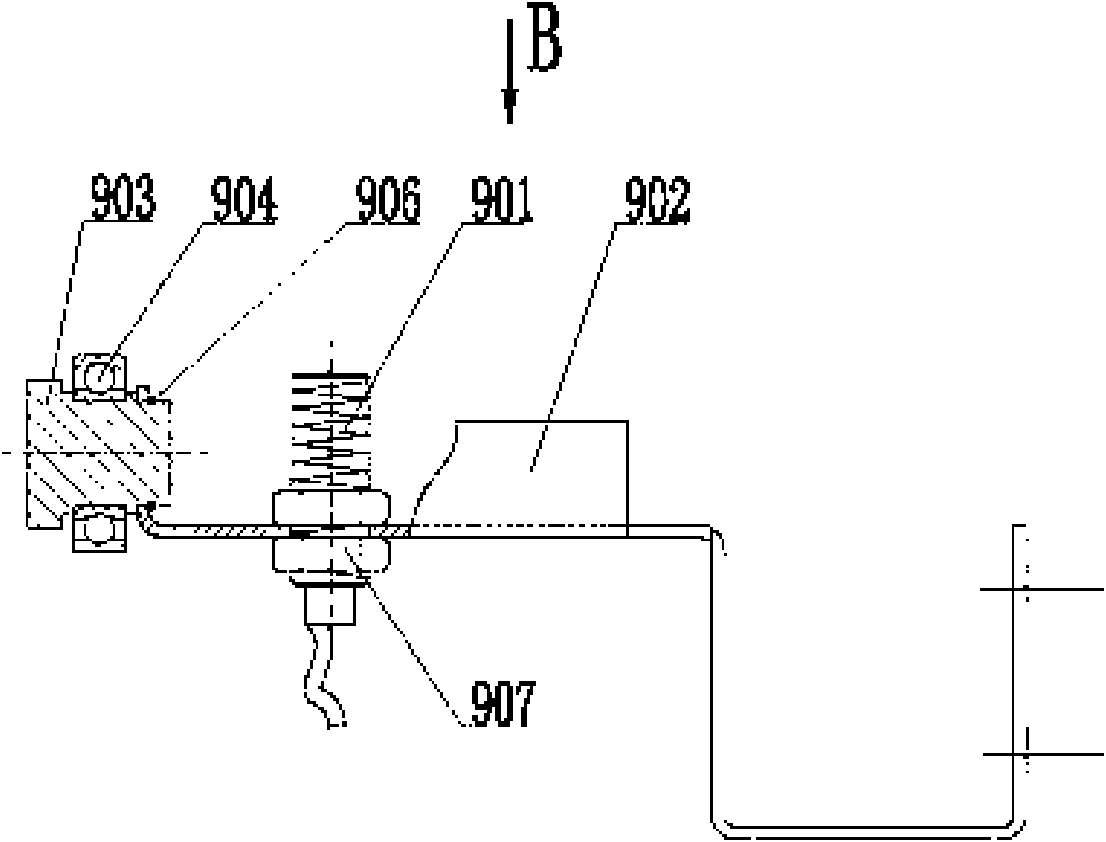

[0025] Such as figure 1 and figure 2 As shown, the present invention is used for the belt deviation detection device of the weighing feeder, which includes a belt position detection device 9 and a belt position sensing element 6 installed on the conveyor belt 4 of the weighing feeder, and the belt position detection device 9 Installed on the frame 1 of the weighing feeder and located below the conveyor belt 4, the belt position detection device 9 can track and detect the position signal of the belt position sensing element 6 in real time, and then according to the position signal of the belt position sensing element 6 Judgment obtains the position where the conveyor belt 4 is located.

[0026] In this embodiment, the belt position sensing element 6 includes more than two sensing strips 61 sequentially arranged along the width directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com