Method for producing CdTe-tamoxifen fluorescent probe

A tamoxifen and probe technology, applied in the field of fluorescent probe preparation, to achieve the effects of easy control of composition, low cost, and good fluorescence characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

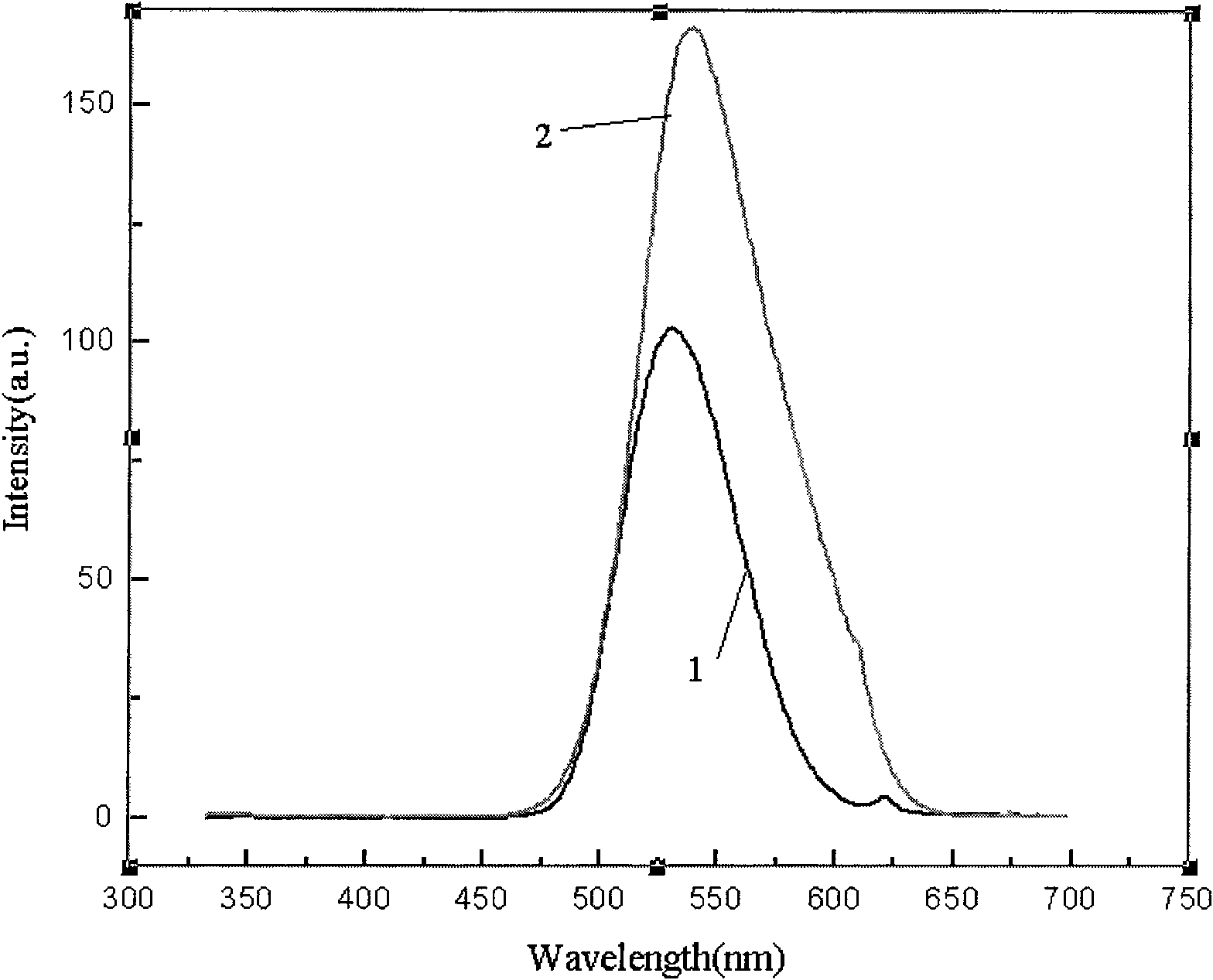

[0018] Dissolve 0.0018g of tamoxifen in 10mL of secondary water, add 10mL of NaHTe to reduce CdCl 2 The pH of the CdTe solution prepared and purified by isopropanol was adjusted to be neutral. Under the protection of nitrogen, the reaction system was heated to 40° C., condensed and refluxed for 60 min to obtain the CdTe-CdTe-tamoxifen fluorescent probe.

Synthetic example 2

[0020] Take 0.0141 g of tamoxifen and dissolve it in 20 mL of secondary water, add 10 mL of the CdTe solution prepared according to the method of Example 1 above, and adjust the pH to be neutral. Under the protection of nitrogen, the reaction system was heated to 100° C., condensed and refluxed for 180 min to obtain the CdTe-tamoxifen fluorescent probe.

Synthetic example 3

[0022] Take 0.0141 g of tamoxifen and dissolve it in 15 mL of secondary water, add 10 mL of the CdTe solution prepared according to the method of Example 1 above, and adjust the pH to be neutral. Under the protection of nitrogen, the reaction system was heated to 60° C., condensed and refluxed for 100 min to obtain the CdTe-tamoxifen fluorescent probe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com