LED constant current driving circuit

A technology of constant current drive and constant current circuit, which is applied in the direction of lamp circuit layout, electric light source, lighting device, etc., can solve the problems of low electrical efficiency, complex circuit, small application range, etc., and achieve stable and reliable brightness, simple circuit, and electrical high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

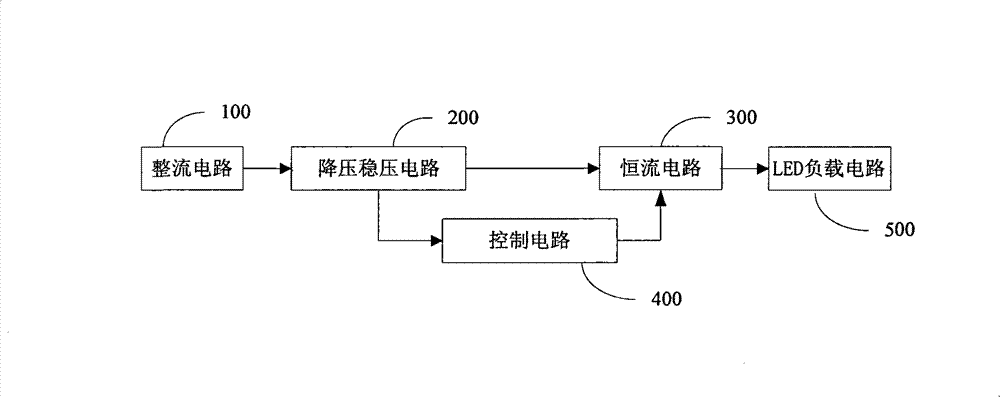

[0019] see figure 1 , which is a circuit block diagram of an embodiment of an LED constant current drive circuit provided according to the present invention, including a rectifier circuit 100, a step-down regulator circuit 200 for stepping down and stabilizing the rectified direct current, and providing LEDs with Constant DC constant current circuit 300 , control circuit 400 for controlling the constant current circuit 300 , and LED load circuit 500 , wherein the constant current circuit 300 is powered by the rectifier circuit 100 , and the control circuit 400 is powered by the step-down regulator circuit 200 .

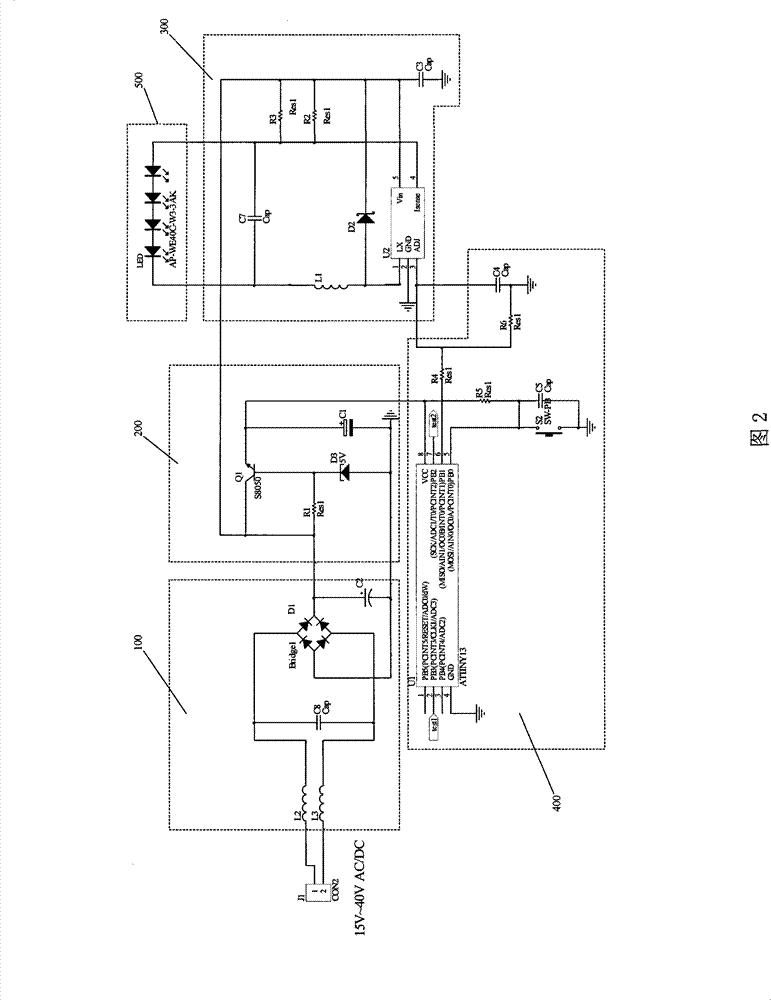

[0020] Such as figure 2 , in the circuit schematic diagram of a preferred embodiment of the present invention, the rectifier circuit 100 is used to convert the input alternating current into direct current, and the rectifier circuit 100 includes common-mode inductors L2, L3, and two common-mode inductors L2 and L3 connected in parallel The filter composed of the saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com