SCR denitrification process and denitrification device of ammonia injection grid adopting non-unidiameter injection orifices

An ammonia injection grid and SCR reactor technology, which is applied in the field of flue gas purification, can solve the problems of increasing the mixing length of ammonia gas/flue gas, affecting the denitration effect, and uneven amount of ammonia gas, achieving compact structure, good implementation effect, Easy to process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

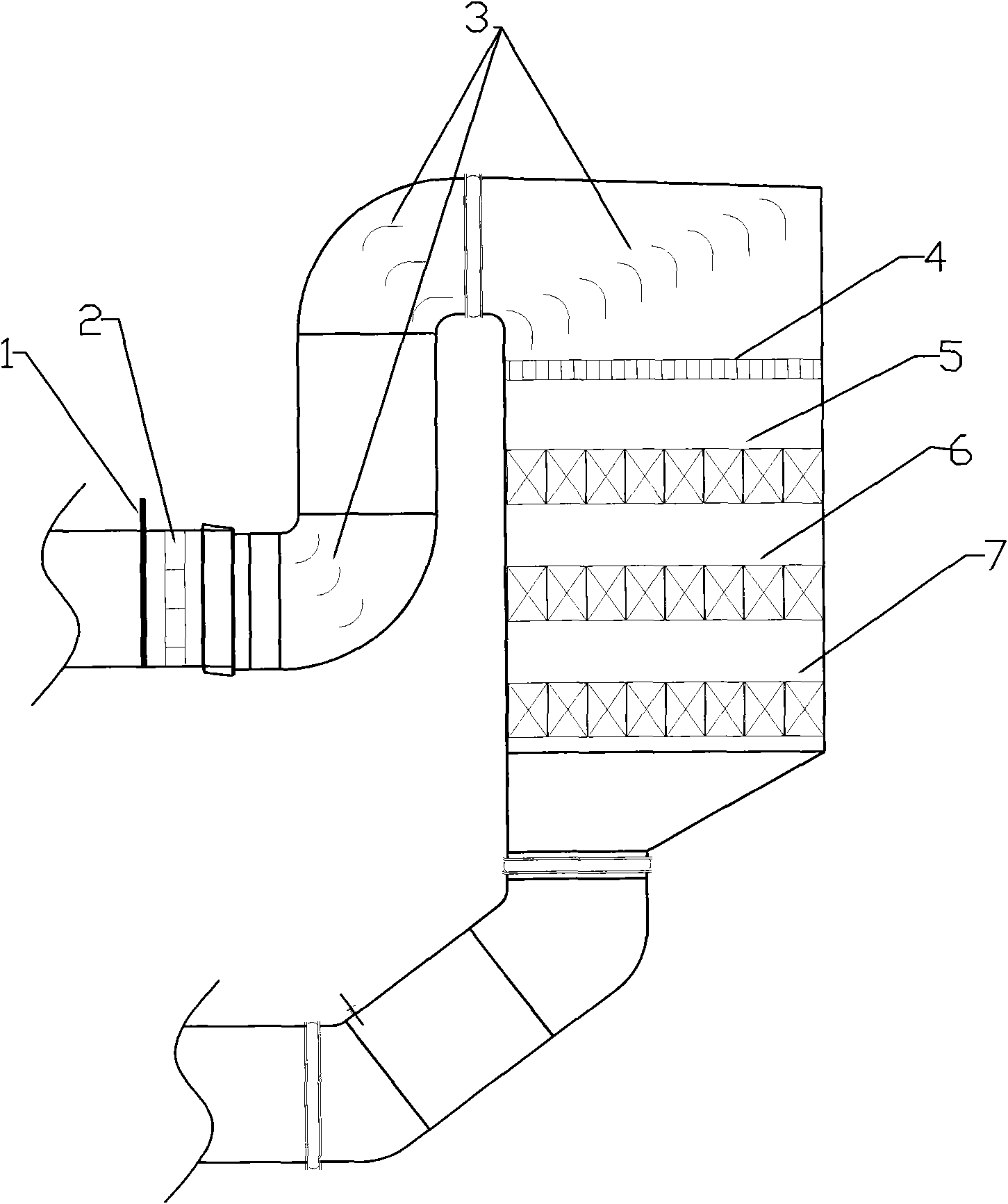

[0028] 1-Ammonia injection grid; 2-Static mixer; 3-Deflector; 4-Rectifier; 5-First catalyst layer; 6-Second catalyst layer; 7-Standby catalyst layer.

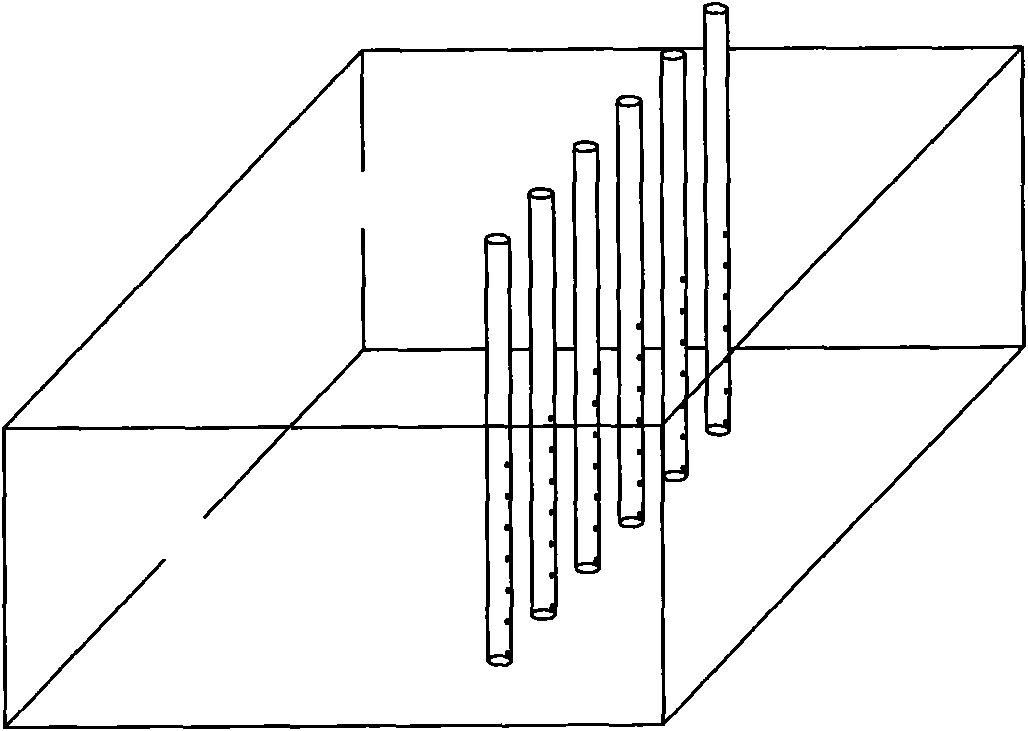

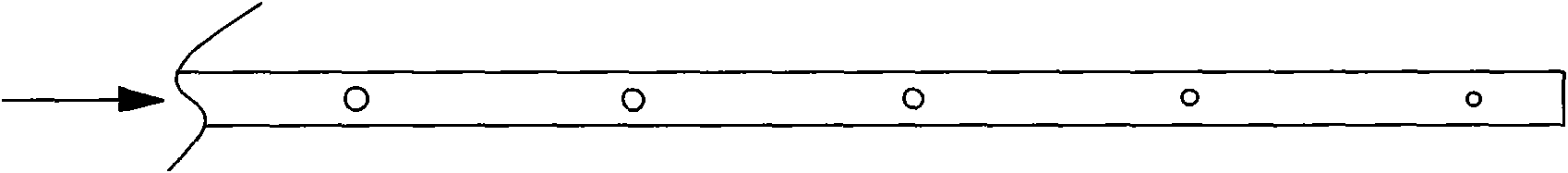

[0029] The SCR denitrification process adopting non-equal-diameter nozzle hole ammonia injection grid of the present invention comprises the following steps: X The flue gas is sent into the ammonia injection grid composed of multiple parallel ammonia injection pipes through the connecting flue. Along the flow direction of ammonia gas, the size of the ammonia injection holes arranged along the axis of the ammonia injection pipe on the ammonia injection grid is gradually reduced. , to ensure that the amount of ammonia ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com