Novel backflow-type micro mixer

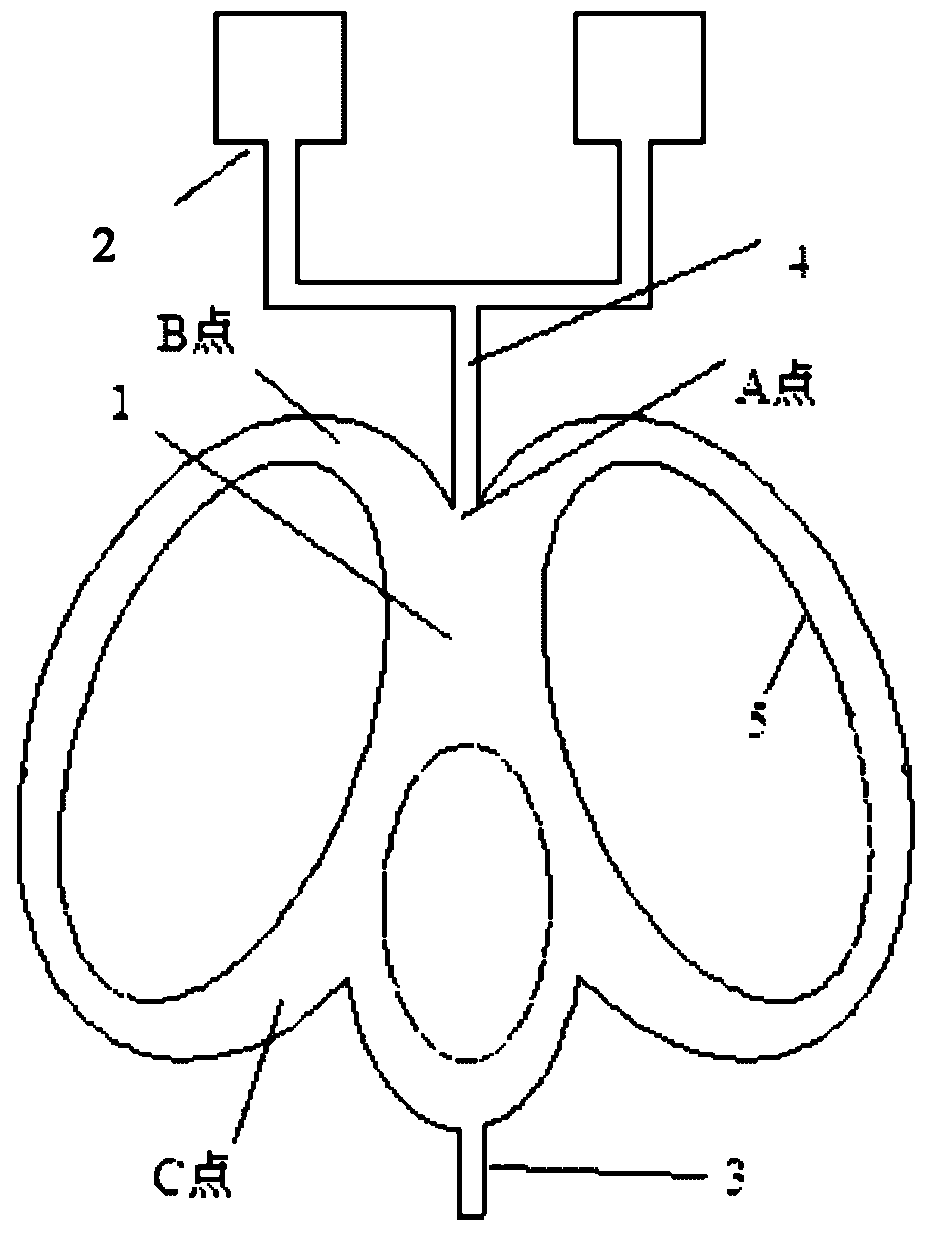

A technology of reflux micro-mixer, which is applied in the field of micro-systems, can solve the problems of low reflux rate and low mixing efficiency, and achieve the effect of increasing reflux rate and mixing rate, improving mixing efficiency, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

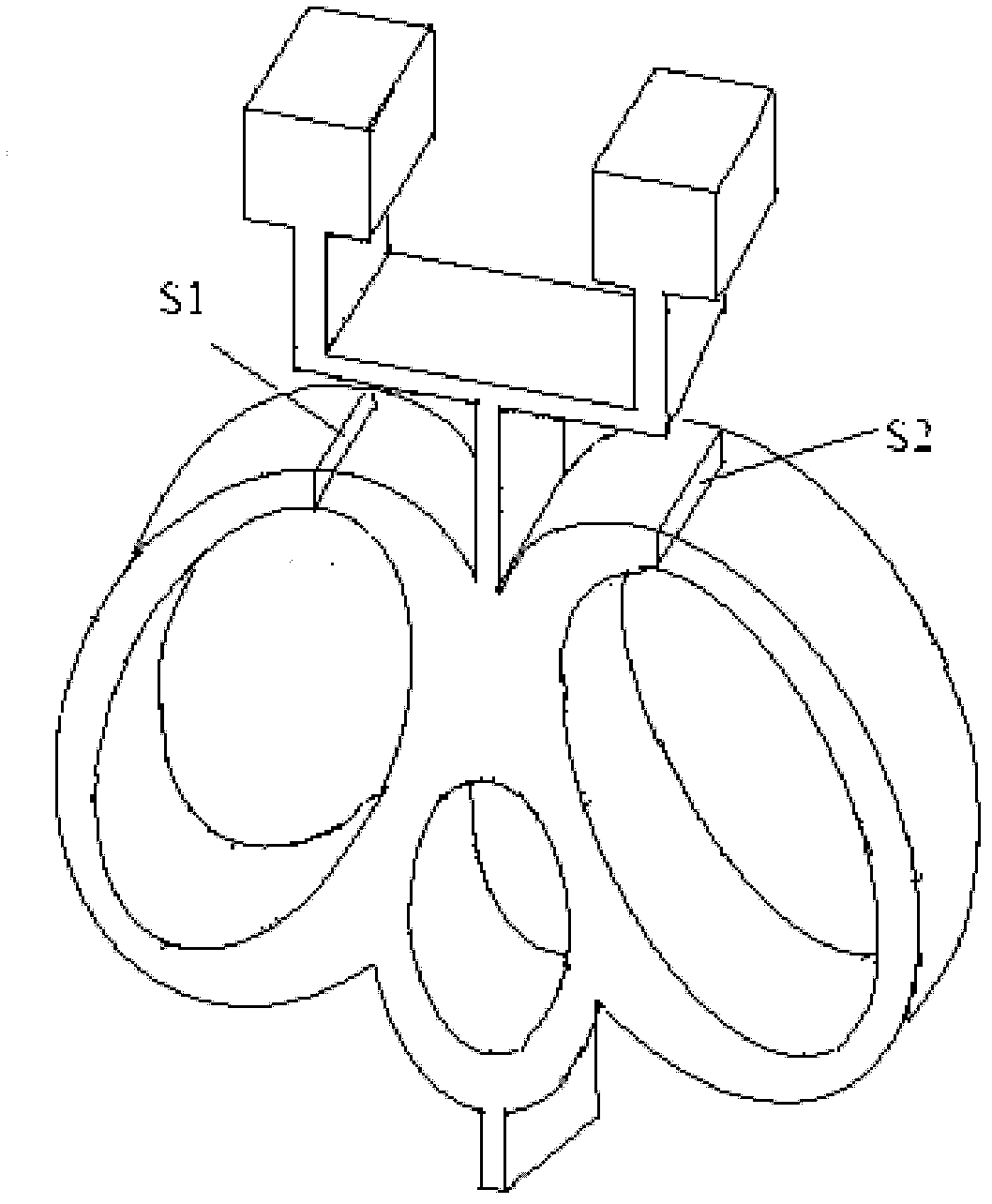

[0026] Example 1: Use ANSYS software to simulate two different fluids with a density of 1000kg / m 3 、1100kg / m 3 , the diffusion coefficient is 10 -9 m 2 / s. The mixer is modeled in 3D, such as figure 2 As shown, the method used is to analyze the multi-component transport in the FLOTRAN / CFD module in ANSYS. The density and viscosity coefficient change with the occurrence of mixing. It is determined whether reflux occurs by observing the direction of the velocity. By observing the density value after mixing Judgment of mixed conditions.

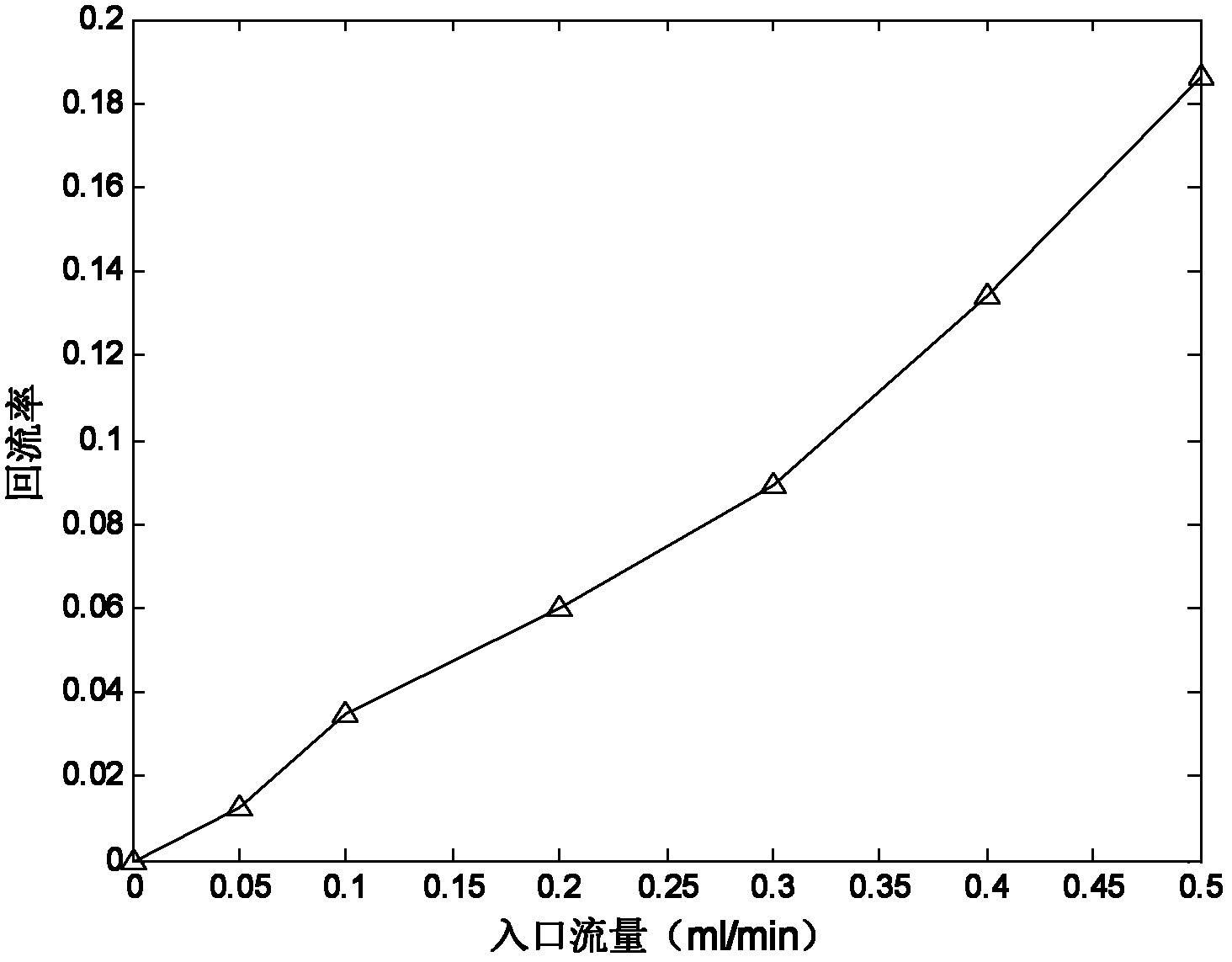

[0027]Backflow is an important indicator of backflow micro-mixers. Uninterrupted backflow can not only increase the mixing length in a limited space, but also cause fluid oscillation, which plays a positive role in promoting mixing. Due to the difference in the structure and size of the mixer and the difference in external stimuli such as flow rate, it has different effects on the size of the return flow. According to the law of fluid mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com