Photographic device inside attachment-type refining furnace

A technology of internal camera device and camera device, which is applied in the direction of furnace, furnace assembly, lighting and heating equipment, etc., to achieve the effect of avoiding complex structure, easy processing and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

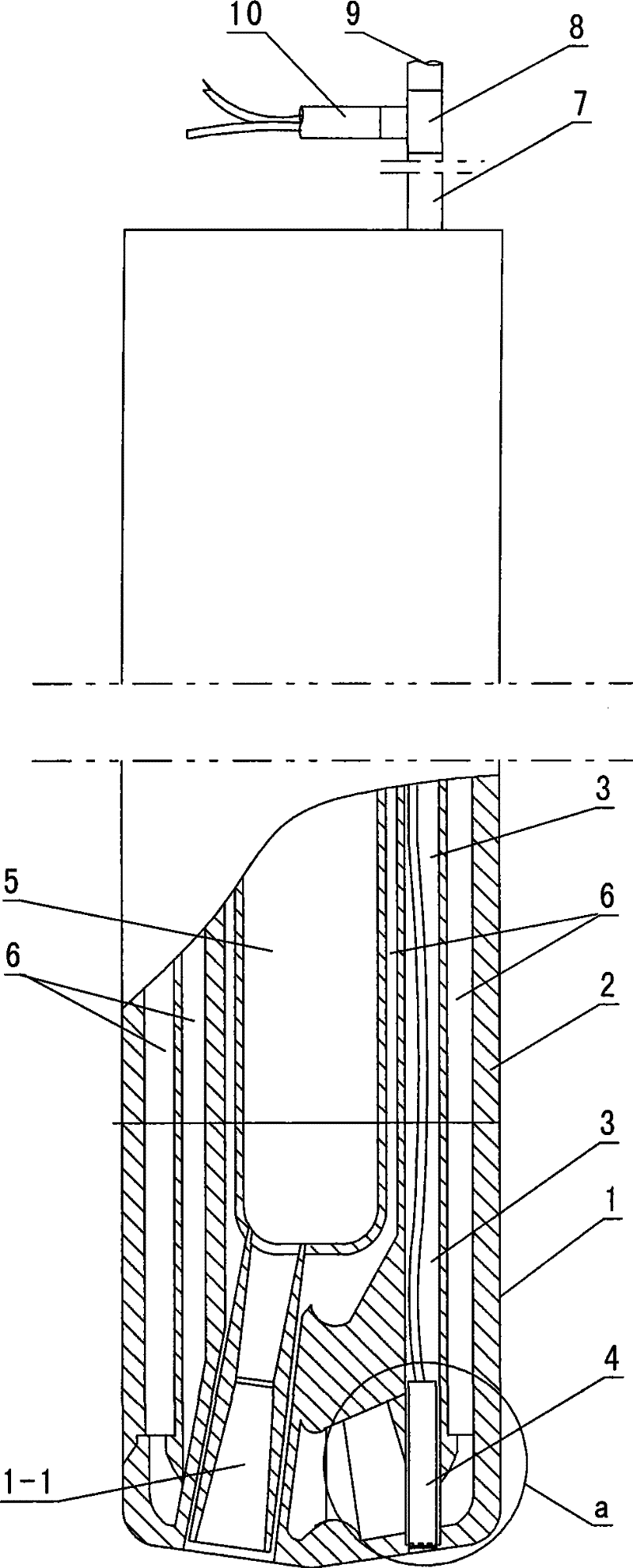

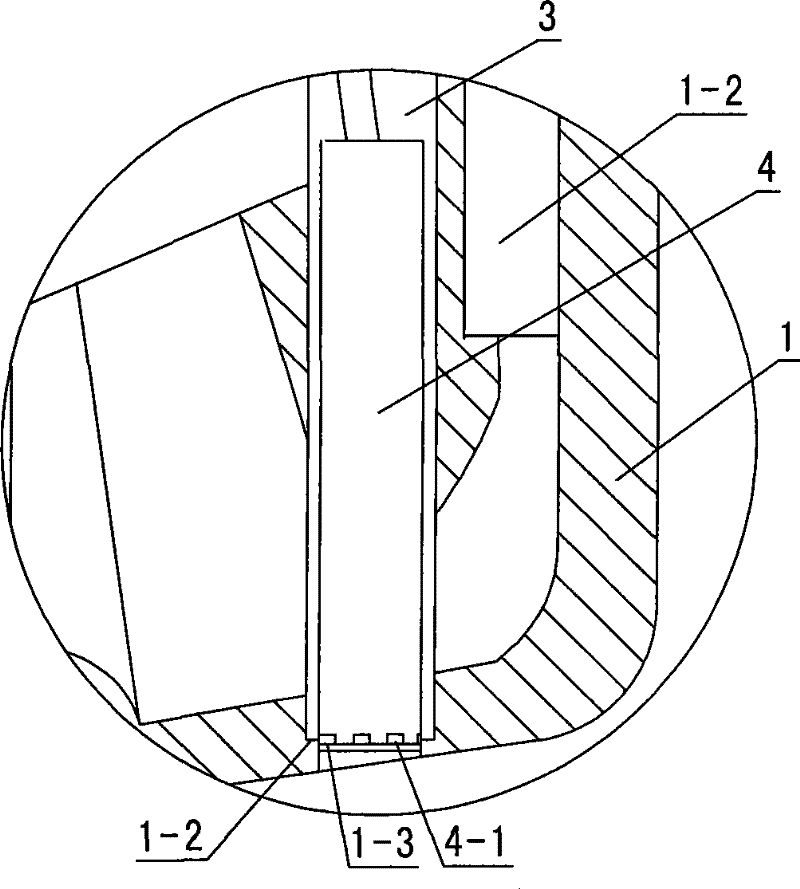

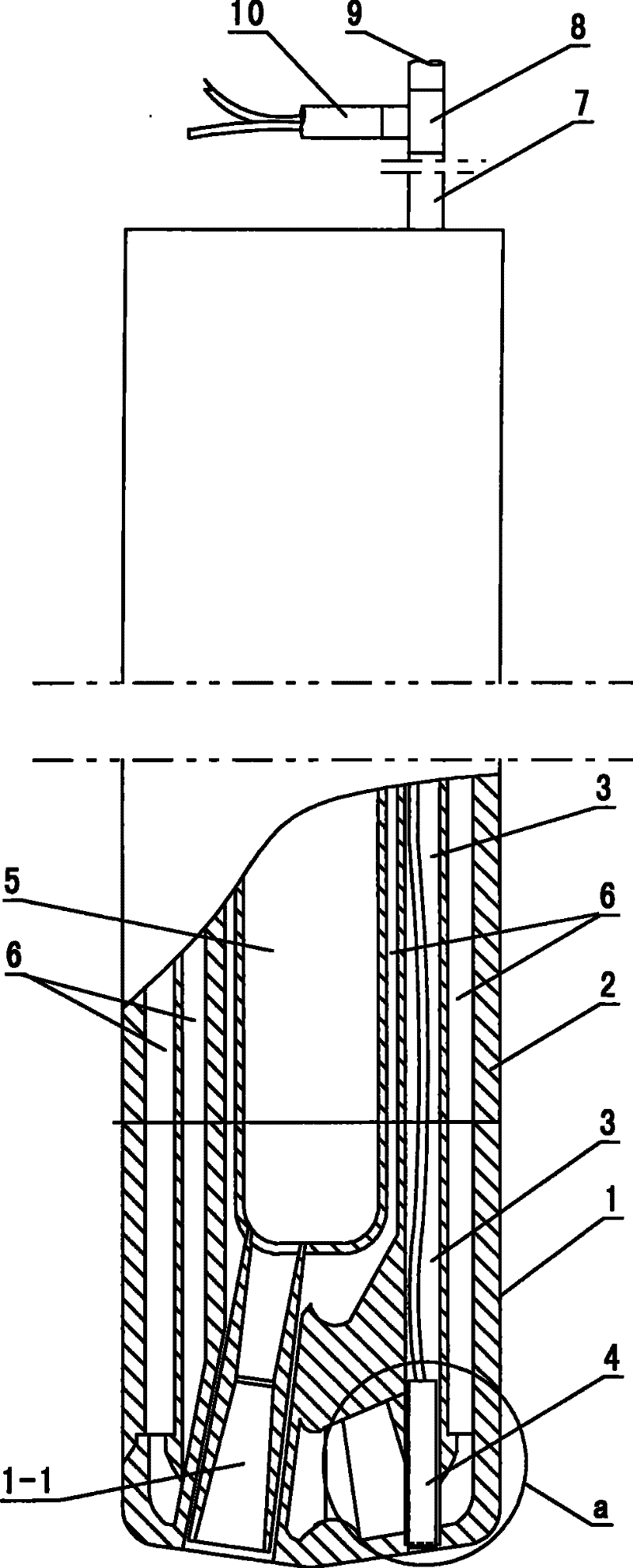

[0016] Such as figure 1 , 2 In the illustrated embodiment, the illustrated top-blown oxygen lance is composed of a modified Laval nozzle 1 and a gun body 2 butt welded. The nozzle 1 is provided with five nozzles 1-1, and an annular oxygen supply channel is arranged around each nozzle. The annular oxygen supply The channel communicates with the main oxygen channel 5 in the gun body 2 . The gun body 2 and the nozzle 1 of the top-blown oxygen lance are provided with a through hole 3 inserted into the camera body 4, and the through hole 3 is connected with the oxygen lance annular water-cooling pipeline 6 .

[0017] The end hole located at the rear end of the gun body through the tunnel is connected with a pipeline 7, and the pipeline 7 is provided with a three-way joint 8, one of which is connected to the cold air input pipeline 9, and the other interface is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com