Bacterial leaching copper method of complex chalcopyrite flotation tailings

A technology of flotation tailings and chalcopyrite type, which is applied to the improvement of process efficiency, photography technology, instruments, etc., to achieve good economic benefits, realize economic benefits and social environmental benefits, and solve the effect of polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

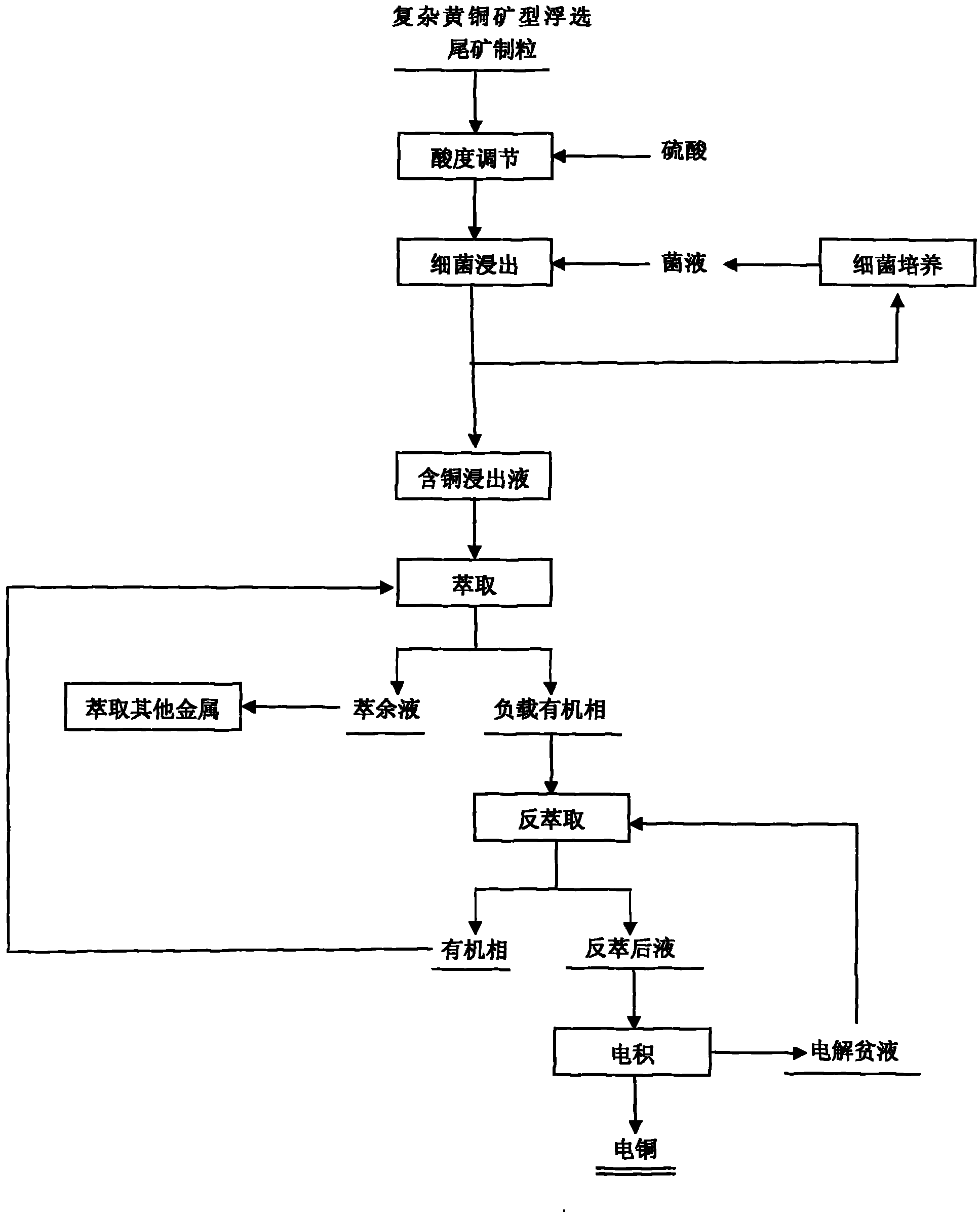

Method used

Image

Examples

Embodiment 1

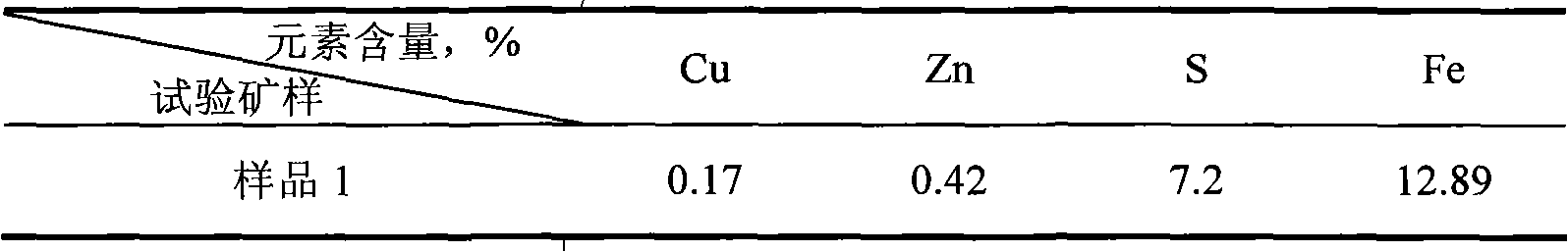

[0024] The chemical analysis of flotation tailings sample 1 is shown in Table 2.

[0025] Table 2 Analysis of chemical composition of tailings sample 1

[0026]

[0027] steps:

[0028] (1) Granulation: Mix flotation tailings, 32.5 cement and water at a volume ratio of 6:1:2 to make granules of 10mm to 20mm, and air-dry them naturally.

[0029] (2) Bacterial cultivation: the mixed bacterial liquid containing Thiobacillus ferrooxidans and Microspiral ferrooxidans is inoculated into 9K culture medium in a 20L plexiglass bacterial oxidation tank with a stirring device, and then expanded and cultivated. The volume ratio of the inoculum is: strain: culture medium = 1:10, the culture temperature is 25°C, the pH value of the culture solution is 1.0-2.0, and the culture time is 48 hours.

[0030] (3) Adjusting the acidity of flotation tailings: put the prepared flotation tailings particles in a plexiglass column of φ90×900mm, and use MP-20RZ magnetic drive circulating pump to s...

Embodiment 2

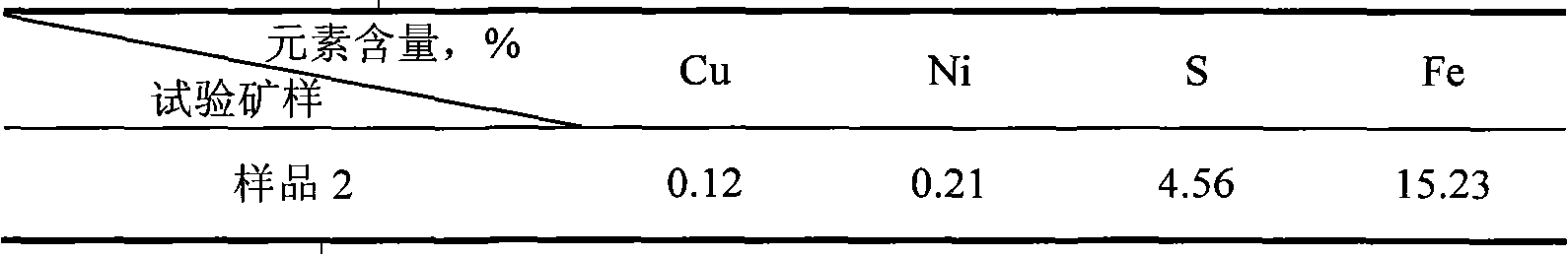

[0036] The chemical analysis of flotation tailings sample 2 is shown in Table 3.

[0037] Table 3 Analysis of chemical composition of tailings sample 2

[0038]

[0039] steps:

[0040] (1) Granulation: mix the tailings, 32.5 cement and water at a volume ratio of 5:1:2 to make 10mm-20mm granules, and let them dry naturally.

[0041] (2) Bacterial cultivation: the mixed bacterial liquid containing Thiobacillus ferrooxidans and Microspiral ferrooxidans is inoculated into 9K culture medium in a 20L plexiglass bacterial oxidation tank with a stirring device, and then expanded and cultivated. The volume ratio of the inoculum is: strain:medium=1:15, the culture temperature is 47°C, the pH value of the culture solution is 1.0-2.0, and the culture time is 24 hours.

[0042] (3) Adjust the acidity of flotation tailings: put the prepared flotation tailings particles in a plexiglass column of φ90×900mm, drive the circulation pump with MP-20RZ magnetic force, and spray the column w...

Embodiment 3

[0048] The chemical analysis of flotation tailings sample 3 is shown in Table 4.

[0049] Table 4 Analysis of chemical composition of tailings sample 3

[0050]

[0051] steps:

[0052] (1) Granulation: Mix flotation tailings, cement of type 42.5, and water at a volume ratio of 7:1:3 to make granules of 10mm to 20mm, and air-dry them naturally.

[0053] (2) Bacterial cultivation: the mixed bacterial liquid containing Thiobacillus ferrooxidans and Microspiral ferrooxidans is inoculated into 9K culture medium in a 20L plexiglass bacterial oxidation tank with a stirring device, and then expanded and cultivated. The volume ratio of the inoculum is: strain: culture medium = 1:20, the culture temperature is 60°C, the pH value of the culture solution is 1.0-2.0, and the culture time is 36 hours.

[0054] (3) Adjust the acidity of flotation tailings: put the prepared flotation tailings particles in a plexiglass column of φ90×900mm, drive the circulation pump with MP-20RZ magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com