Test method of magnetically controlled reactor

A technology of magnetron reactor and test method, applied in the direction of instruments, measuring electricity, measuring electrical variables, etc., can solve problems such as inability to simulate actual use conditions, difficulty in on-site processing, inability to achieve rated voltage and rated load status, etc. The effect of avoiding power outages in the whole plant, saving costs and increasing output capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

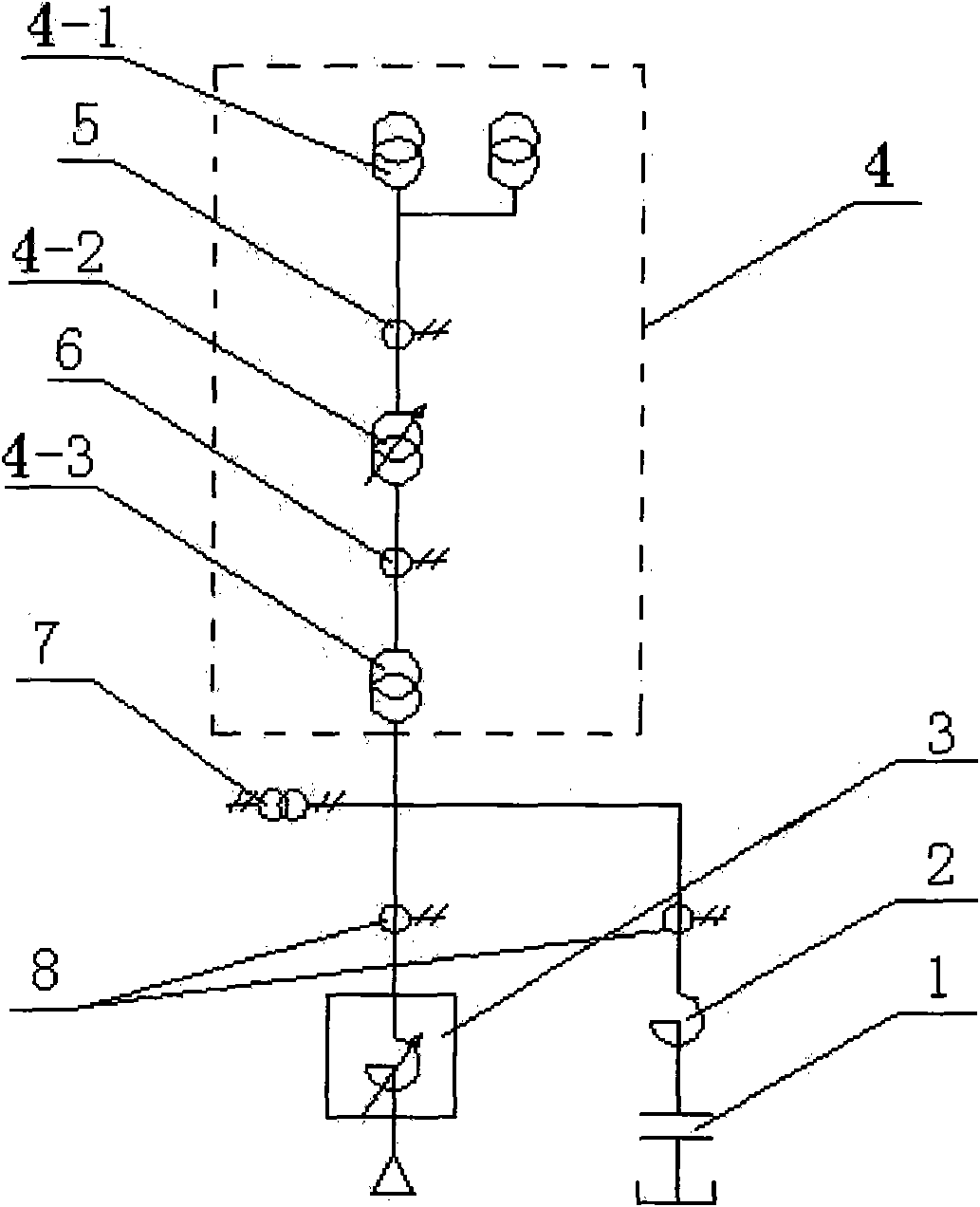

[0012] see figure 1 , the embodiment of a kind of magnetron reactor testing method of the present invention, the series loop that capacitor bank 1 and reactor 2 are formed is connected with magnetron reactor 3 in parallel and connected to test transformer 4, and test transformer 4 is composed of power transformer 4-1 , a voltage regulating transformer 4-2, a step-up transformer 4-3 and a current transformer 5,6. When the capacity of the test transformer 4 is insufficient, the capacitive reactive power of the capacitor bank 1 is used to compensate the test transformer 4, so that the magnetron reactor 3 is tested under full load. The test process adopts the parallel resonance method. Firstly, the output voltage of the test transformer 4 is adjusted, and then the control pulse output by the controller of the magnetic control reactor 3 is changed to change the output capacity of the magnetic control reactor 3 so that it is compatible with the capacitor bank 1 and the reactance. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com