Jawbone repair support and manufacture method thereof

A mandible and mandible technology, which is applied in the field of mandibular repair brackets and manufacturing, can solve the problems that morphological repair cannot meet the clinical requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

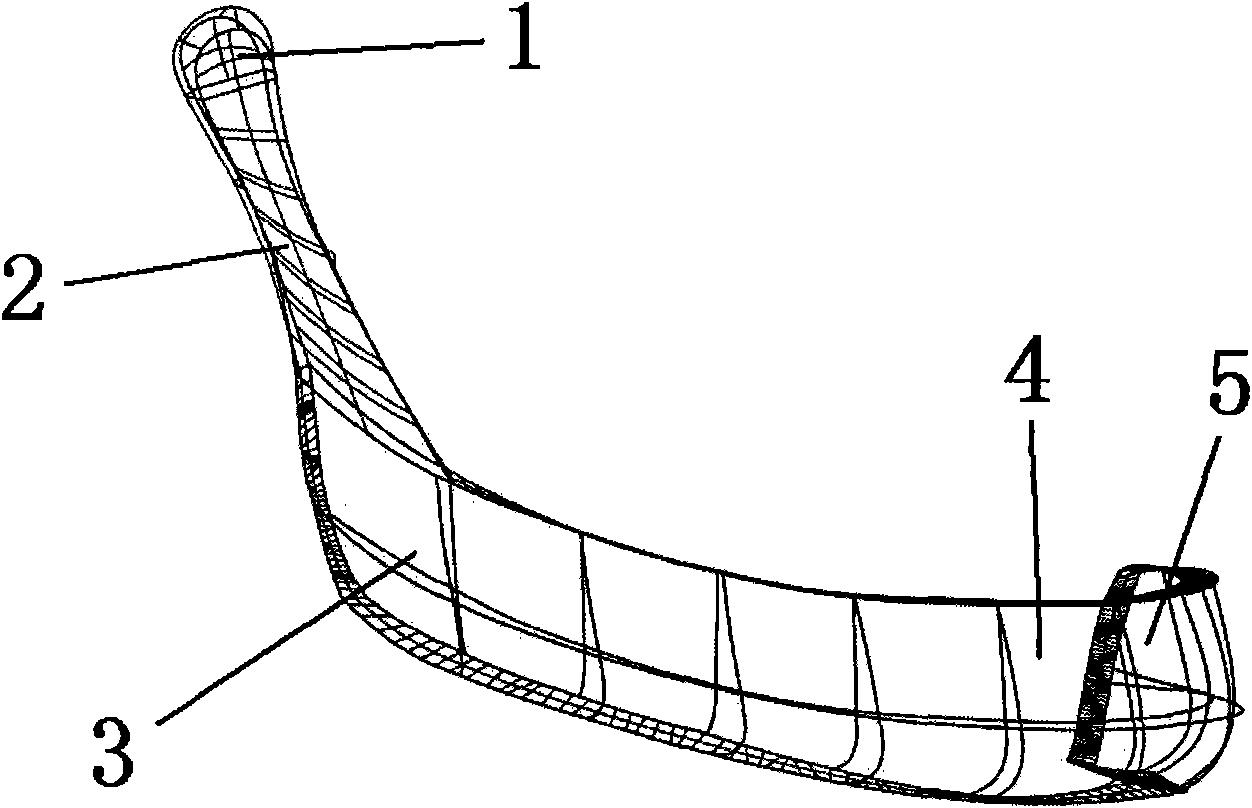

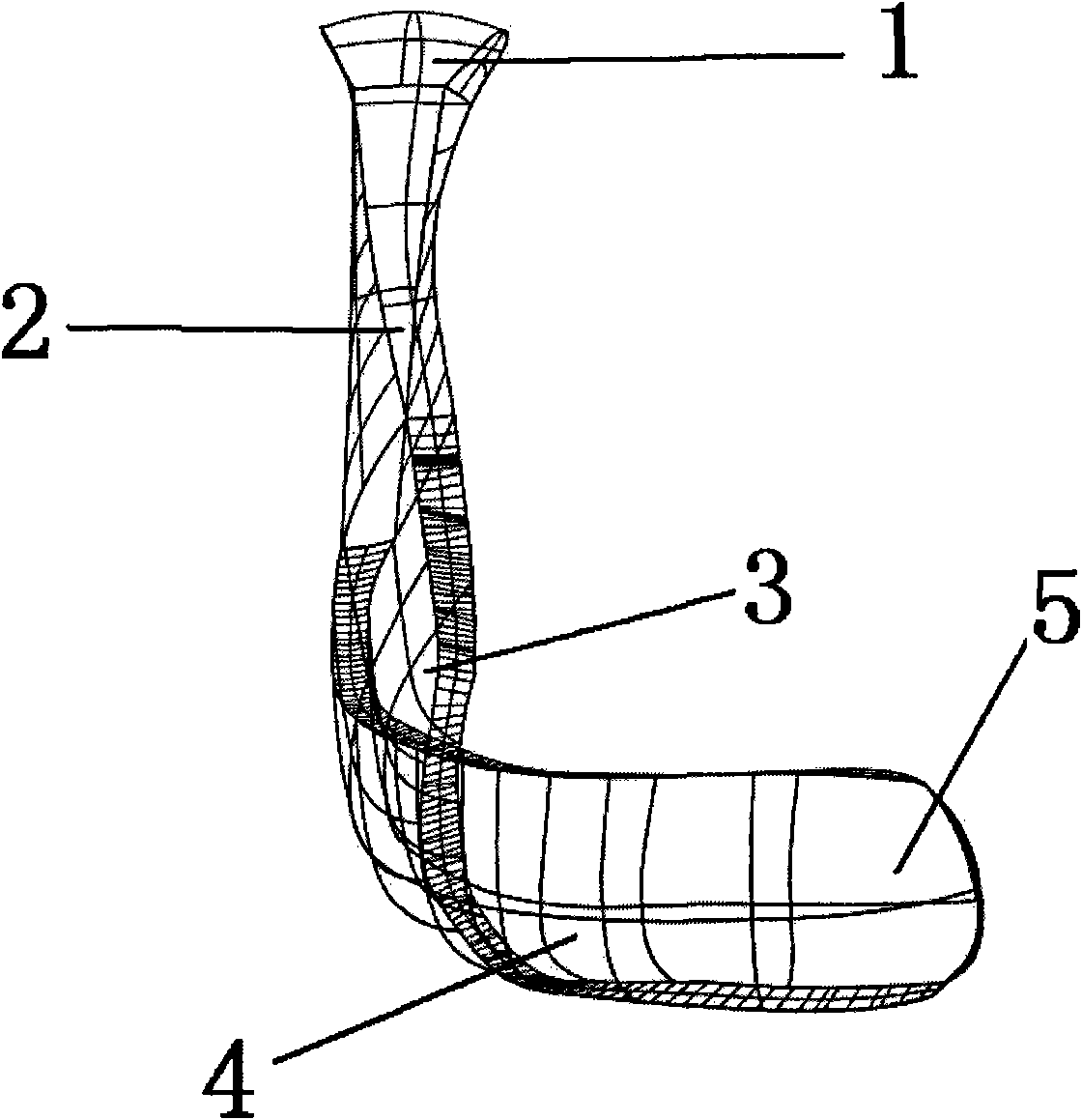

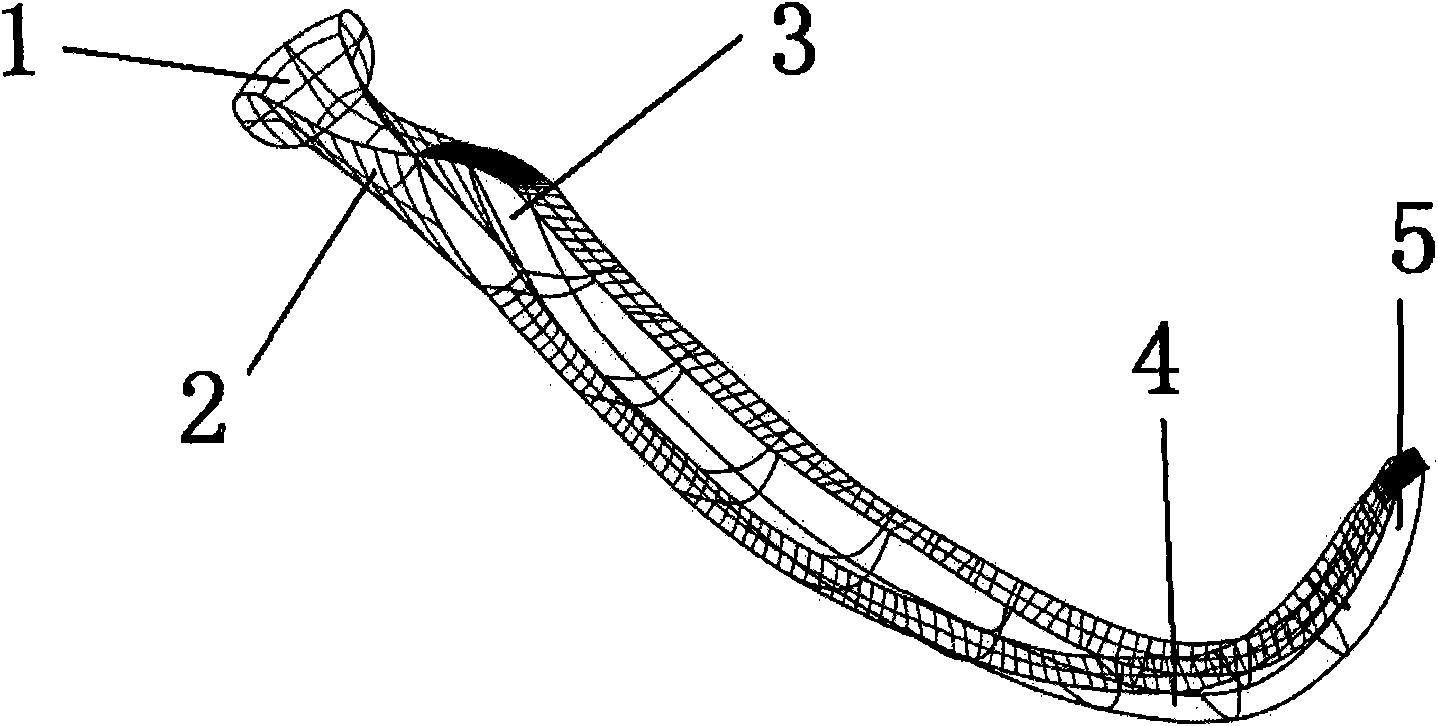

[0028] Below with the accompanying drawings ( Figure 1-Figure 4 ) to illustrate the present invention.

[0029] figure 1 It is a structural schematic diagram of the first mandibular repair bracket of the present invention, figure 2 It is a schematic structural view of the second mandibular repair bracket of the present invention, image 3 It is a structural schematic diagram of the third mandible repair bracket of the present invention. Such as figure 1 , figure 2 and image 3 As shown, the mandibular repair bracket includes a mandible-shaped bracket body, and the mandible-shaped bracket body has successively distributed condyle region 1, mandibular ramus region 2, mandibular angle region 3, mandibular bone graft region 4 and bone Connection area 5; both the mandibular angle area 3 and the mandibular bone graft area 4 have a through hole array structure, and the bone connection area 5 has a counterbore array structure.

[0030] The diameter of the counterbore in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com