Sack-duster pulse blowing test device and test method thereof

A technology of bag dust collector and pulse injection, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of damage to filter bags, high resistance of filter bags, and influence on cleaning effect, and achieve improved structure , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

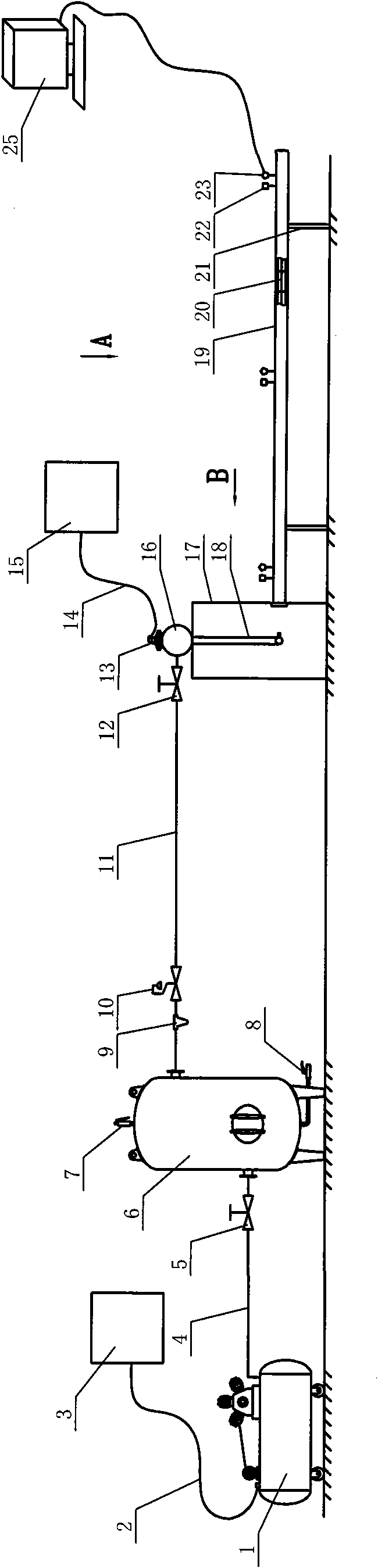

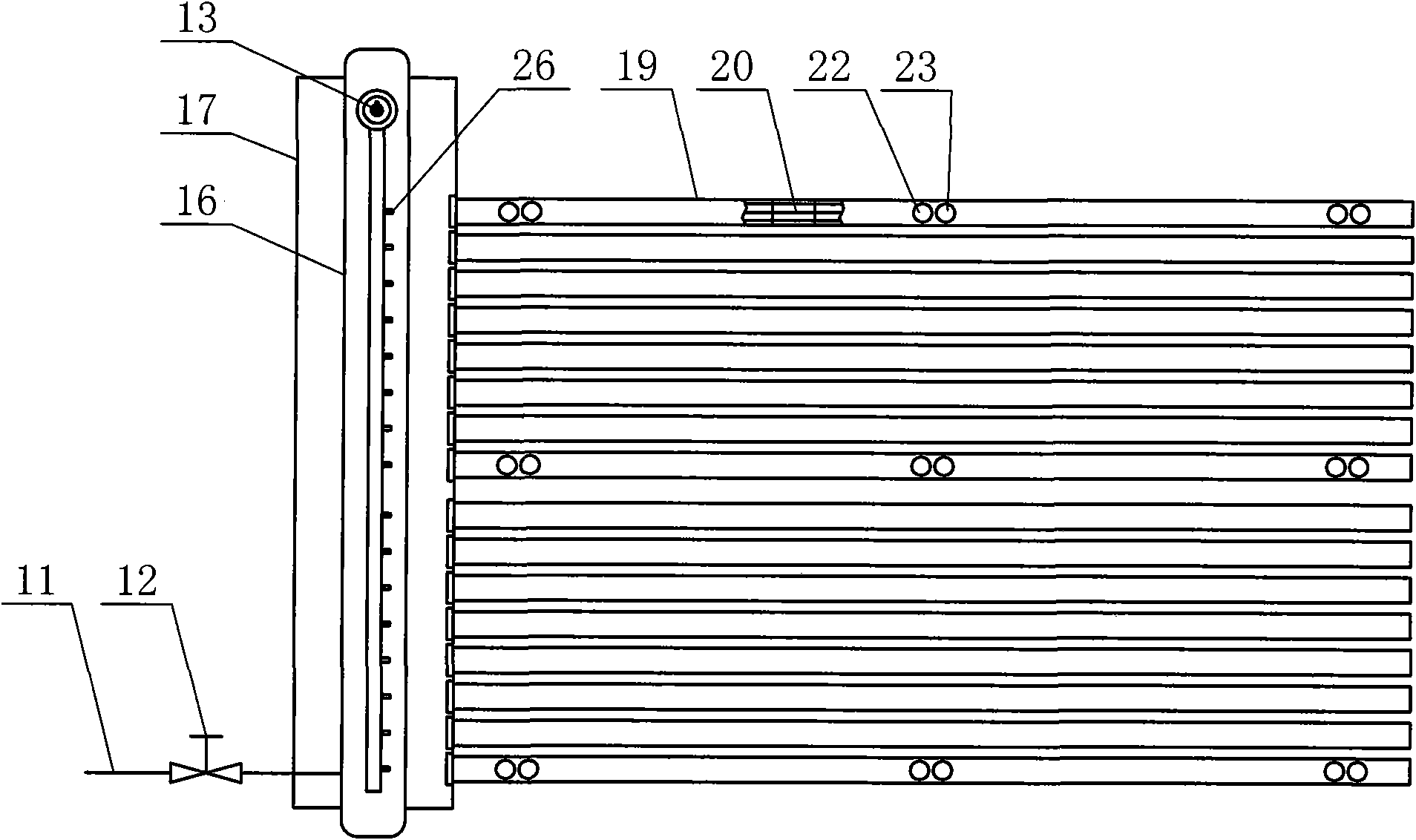

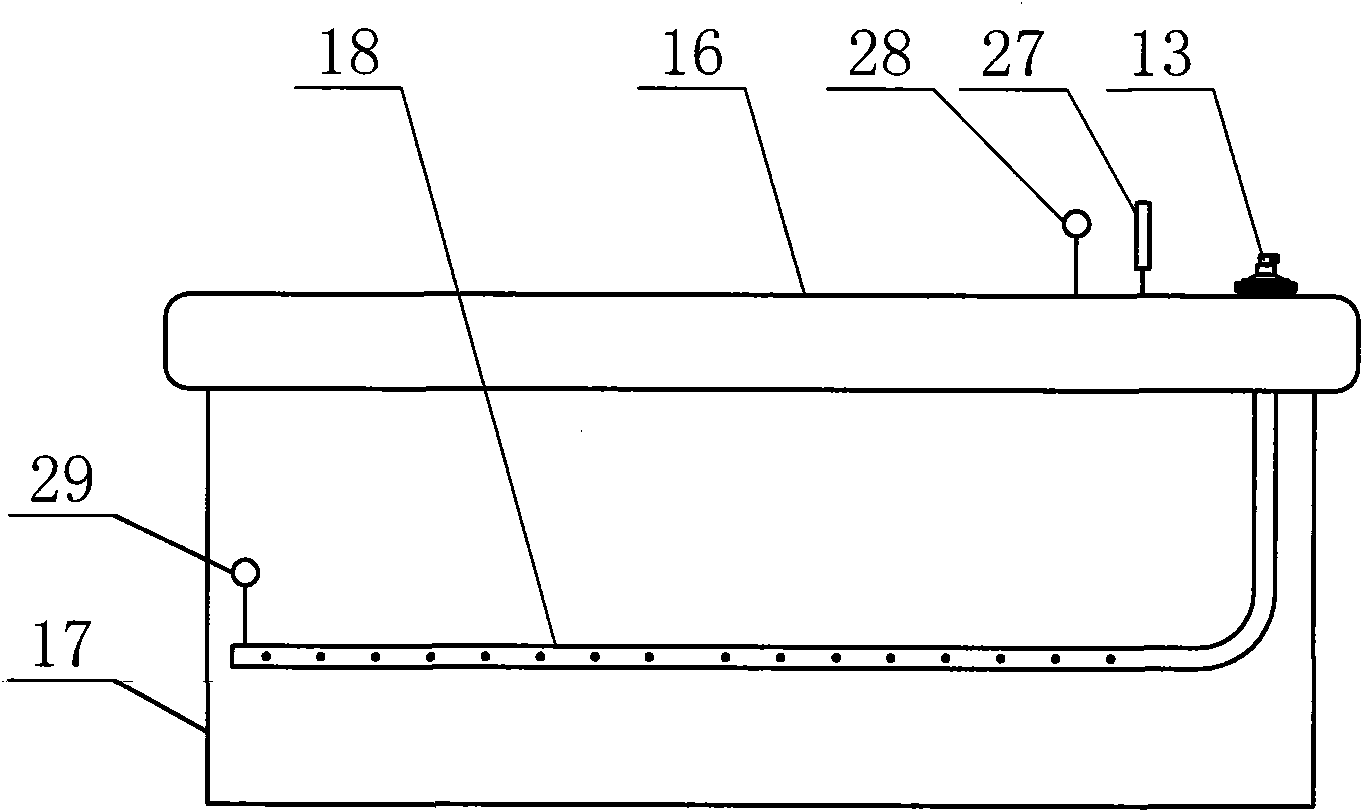

[0017] Example 1: A bag filter pulse injection test device

[0018] like figure 1 , figure 2 and image 3 As shown, it includes an air compressor 1, an electric control box 3, a safety valve 7 at the top, an air storage tank 6 with a water release valve 8 at the bottom, an air filter 9, a pulse valve 13, a pulse controller 15, an air bag 16 and the blowing pipe 18 with sixteen nozzles 26, one end of the air compressor 1 is connected with the electric control box 3 through the wire 2, and the other end is connected with the stop valve 5 and the left interface of the gas storage tank 6 through the pipeline 4 in turn, The right interface of the air storage tank 6 is connected to the air filter 9, the pressure reducing valve 10, the stop valve 12, and the pulse valve 13 in sequence through the pipeline 11. Connection, the injection pipe 18 with sixteen nozzles 26 passes through the air bag 16 and is connected to the pulse valve 13. The pulse valve 13, the injection pipe 18 and...

Embodiment 2

[0019] Embodiment 2: a kind of test method of pulse valve single injection air volume

[0020] Using the bag filter pulse injection test device described in Example 1, after filling the air bag 16 with compressed air, close the stop valve 12, set the opening and closing time of the pulse valve 13 by the pulse controller 15, and then open the pulse valve 13. Blowing, turn on the data acquisition instrument 25 at the same time, collect the pressure P1 in the air bag 16 before the injection, the pressure P2 in the air bag 16 after the injection and the temperature t of the compressed air in the air bag 16 through the data acquisition instrument 25, and then combine Knowing the local atmospheric pressure P0 and the volume V of the air bag 16, through the formula The single blowing air volume Q of the pulse valve 13 is calculated. The obtained pulse valve single injection air volume Q can be used to evaluate the performance of different types and batches of pulse valves; it can a...

Embodiment 3

[0021] Embodiment 3: A kind of test method of pressure change of blowing pipe end

[0022] Using the bag filter pulse injection test device described in Example 1, the air bag 16 is filled with compressed air, and the opening and closing time of the pulse valve 13 is set by the pulse controller 15, and then the pulse valve 13 is opened for injection, and simultaneously The data acquisition device 25 collects the pressure change data from the high pressure pressure sensor 29 on the blowing pipe 18 through the data acquisition device 25 . The obtained data of the pressure change of the injection pipe can be used to analyze and improve the design of the injection pipe, and to clarify the change of the injection pipe pressure when the parameters such as the size of the injection pipe and the diameter of the injection nozzle are changed, so as to guide the design of the updated injection pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com