Multi-channel metal palladium or palladium alloy composite membrane hydrogen separator

A composite membrane and multi-channel technology, applied in hydrogen separation, semi-permeable membrane separation, separation methods, etc., can solve the problems of leakage at the graphite gasket, difficulty in application, and different thermal expansion coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

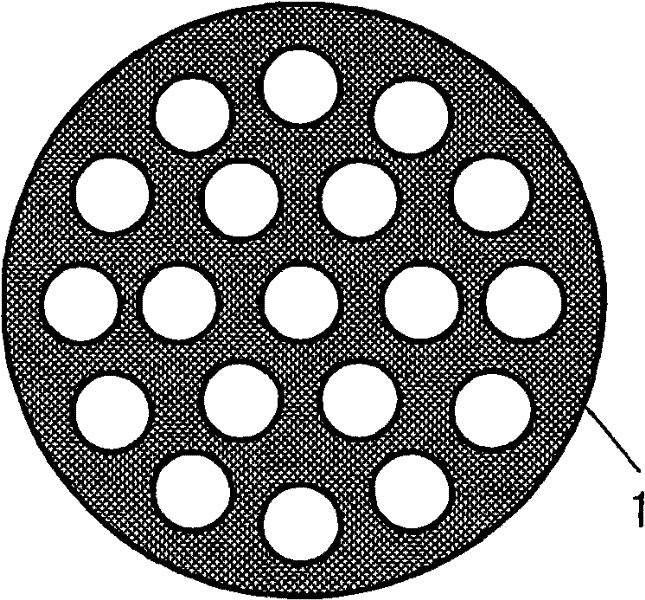

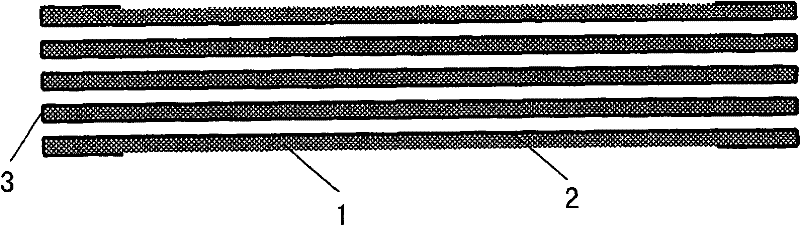

[0036] Take multi-channel Al 2 o3 The ceramic tube 1 is used as the support body of the metal-palladium-gold composite membrane 2, and its length is 250 mm, and its diameter is 30 mm. Multi-channel Al 2 o 3 The ceramic tube is composed of 19 channels with a diameter of 4mm. The cross-sectional schematic diagram is shown in figure 1 . Adopt conventional electroless plating method, form continuous palladium film on the inner surface of multi-channel ceramic tube, the cross section 3 of two and the outer surface apart from end 30mm, the thickness of palladium film is about 5 μ m (its profile is as follows figure 2 shown). A graphite sealing ring 4 is used to connect and seal the multi-channel metal-palladium composite film and the metal joint 5 at a distance of about 10 mm from the end of the multi-channel metal-palladium composite film. Then the metal joint 5 is connected with the separator housing 6 to form a hydrogen separator, one end of which is connected with a metal ...

Embodiment 2

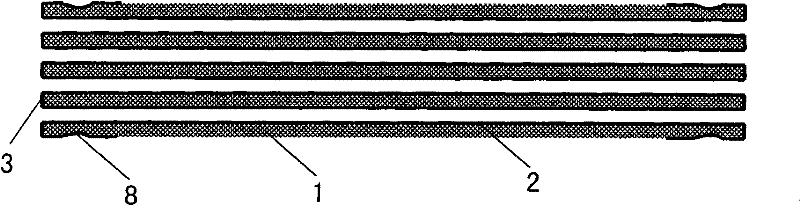

[0054] Take multi-channel Al 2 o 3 The ceramic tube 1 is used as the support body of the metal-palladium-silver alloy composite film 2, and its length is 250mm and its diameter is 30mm. Multi-channel Al 2 o 3 The ceramic tube is composed of 7 channels with a diameter of 6 mm. Grooves 8 are respectively opened on the outer surface 10mm away from the two ends, the width of the grooves is 1.5mm, and the depth is 0.15mm. Adopt conventional electroless plating method, form continuous palladium-silver alloy film (its profile is as image 3 shown). The thickness of the palladium-silver alloy film is about 4.8 μm, and the ratio of palladium / silver is 74 / 26. A graphite sealing ring 4 is used to connect and seal the multi-channel metal palladium-silver alloy composite film 2 and the metal joint 5 at the groove 8 on the outer surface of the multi-channel metal palladium-silver alloy composite film. Then the metal joint 5 is connected with the separator housing 6 to form a hydrogen...

Embodiment 3

[0065] Take multi-channel Al 2 o 3 The ceramic tube 1 is used as the support body of the metal-palladium composite membrane 2, and its length is 250 mm, and its diameter is 30 mm. Multi-channel Al 2 o 3 The ceramic tube is composed of 19 channels with a diameter of 4mm. There is a slope 9 between the two ends and 40mm away from the end, the diameter at the end is 30.3mm, and the diameter at 40mm away from the end is 30mm. Adopt conventional electroless plating method, form continuous palladium film (its profile is such as Figure 4 shown). The thickness of the palladium film is about 5.2 μm. A graphite sealing ring 4 is used to connect and seal the multi-channel metal-palladium composite film and the metal joint 5 at a distance of about 10 mm from the end of the multi-channel metal-palladium composite film. Then the metal joint 5 is connected with the separator housing 6 to form a hydrogen separator, one end of which is connected with a curved metal tube 7 to release th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com