New construction method for elastic concrete in longitudinal spliced seams of roads and bridges

A technology for elastic concrete and highway bridges, applied in bridges, bridge parts, bridge construction, etc., can solve the problems of difficult control of heating temperature, elastic asphalt and aggregate mix ratio can not meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

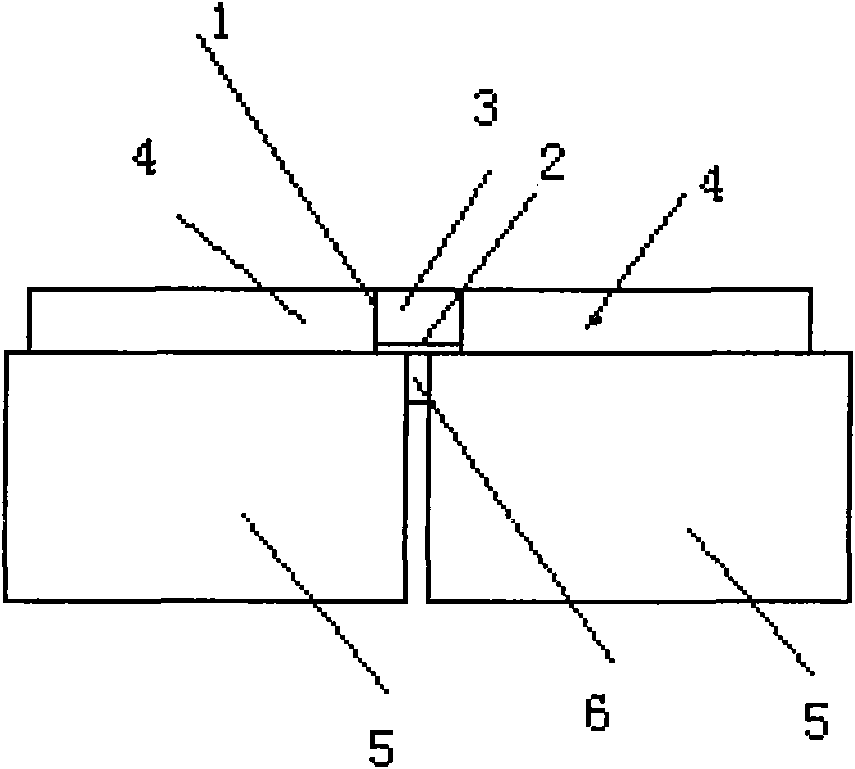

[0009] Embodiment: In the construction of the longitudinal seam of the bridge, a groove 1 with a width of 30-40 cm can be excavated at the longitudinal seam of the old and new bridges, and the groove 1 is cleaned. The bottom is coated with bonding material, and the bottom is treated with steel plate 2. Then pour the elastic concrete 3 produced by mixing into the trench 1, and then treat the surface, and open to traffic after cooling for two hours. In the figure, 4 is an asphalt pavement, 5 is a concrete beam, and 6 is filled with sponge.

[0010] After the elastic concrete is applied to the construction of the longitudinal joints of the old and new bridges, a continuous whole is formed at the longitudinal joints, and the filling surface is flat and seamless. Even if the settlement of the old and new bridges is uneven, the longitudinal joints are still a Gentle slope, it will not form a sudden change in height difference to hinder driving safety, making driving more stable, co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap