Sink roll with sealing device

A sinking roller and belt sealing technology, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of easy wear of sealing rings, affecting production efficiency, and poor sealing performance, so as to ensure sealing effect, improve production efficiency, The effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

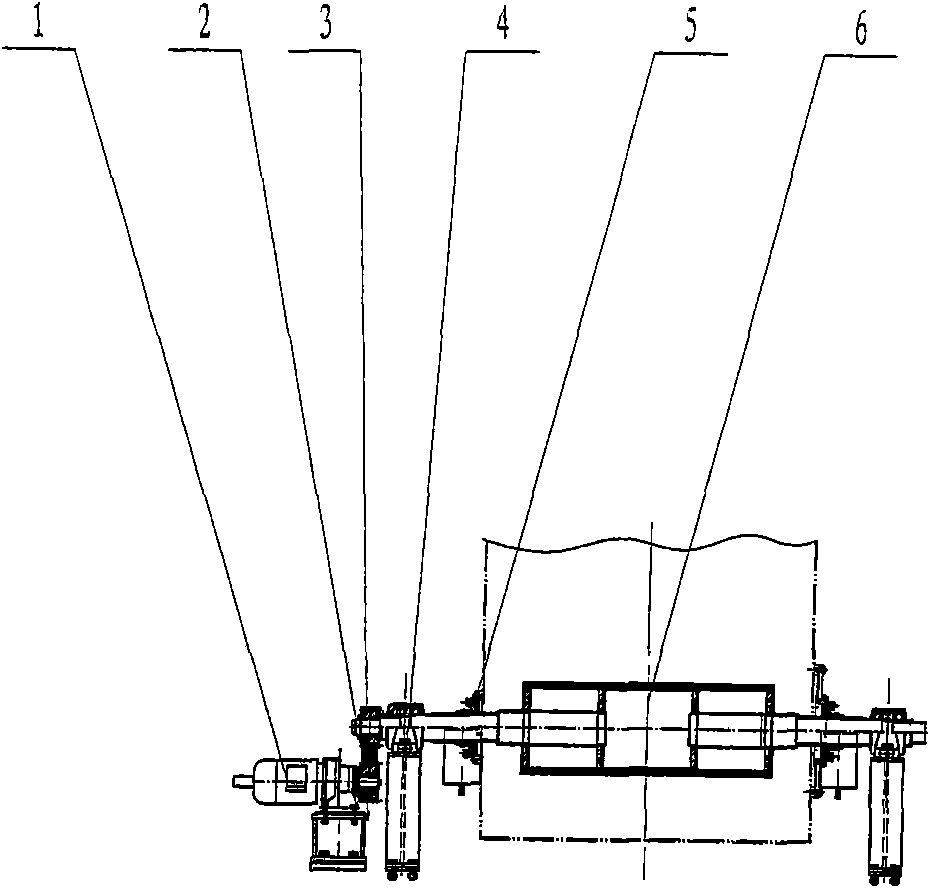

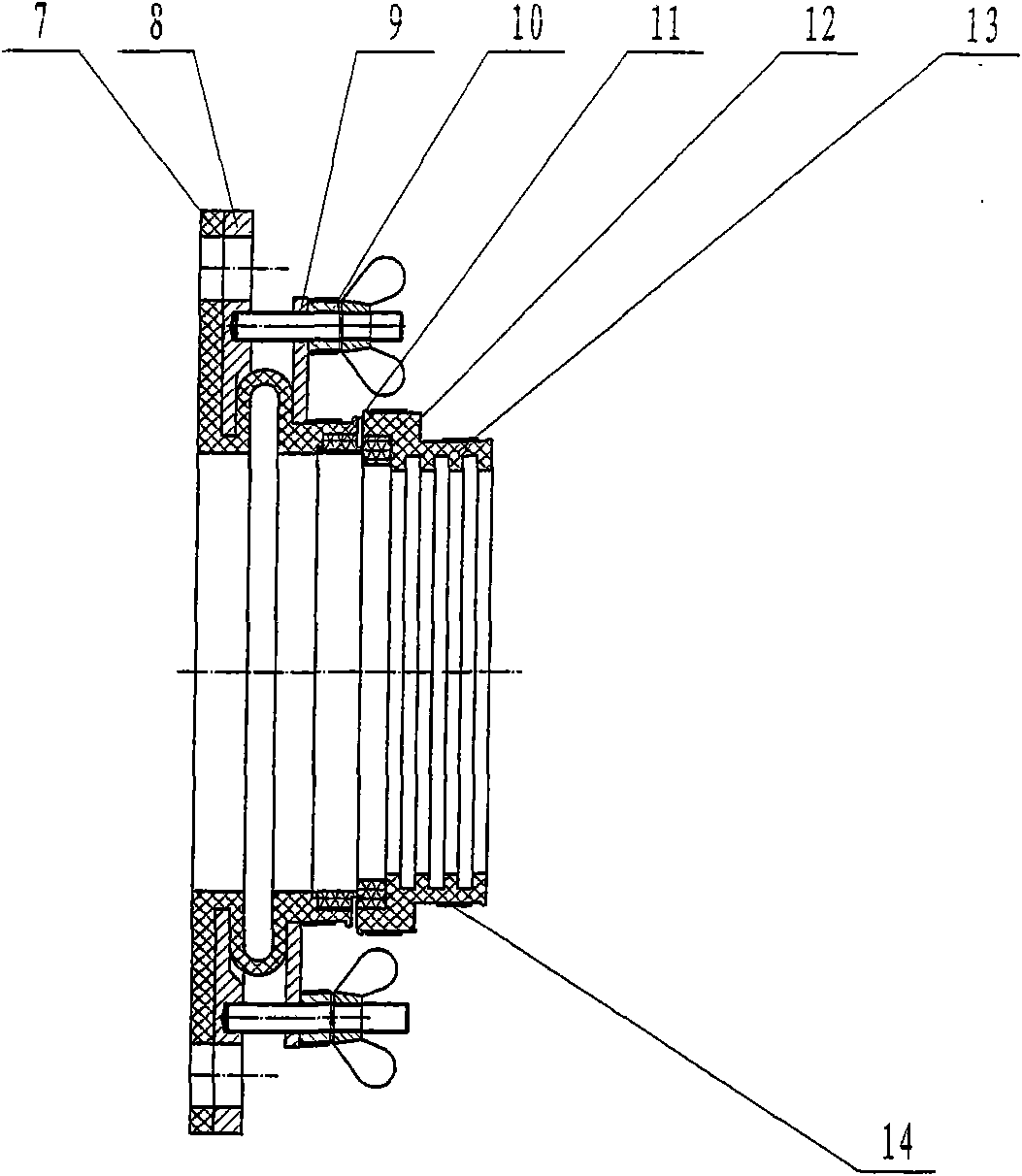

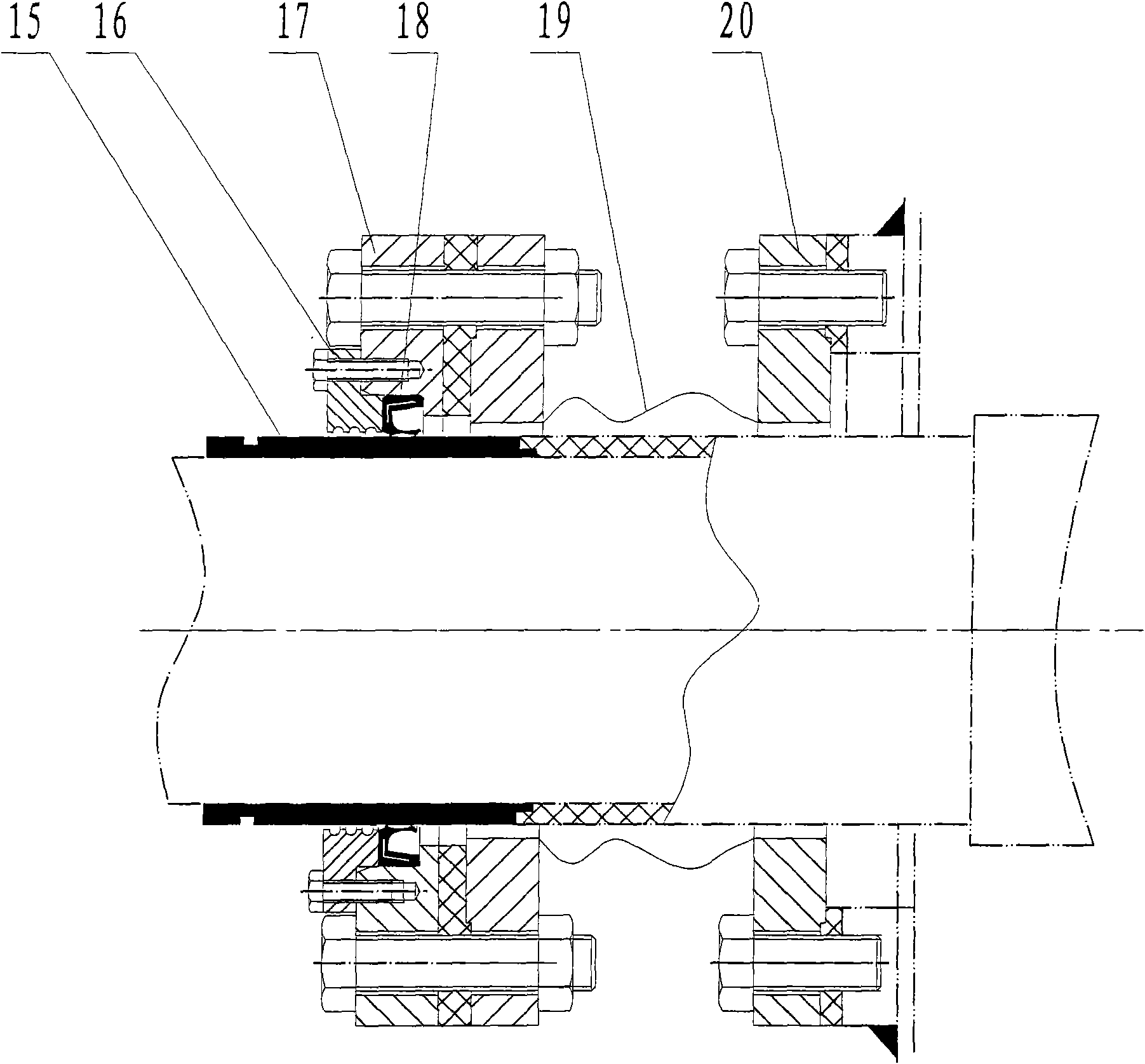

[0010] exist figure 1 The sinking roller is used for immersing in the bath liquid. The sinking roller is supported on the base outside the tank by the sinking roller bracket. The sinking roller is immersed in the bath liquid. The rollers are fixed on the trough. On one side of the sinking roller, the motor 1 decelerates to drive the synchronous wheel mechanism 3 to rotate, and the synchronizing mechanism installed on the shaft head drives the sinking roller to rotate, and drives the strip to move forward. The sealing mechanism includes corrugated pipe compensator (7), flange (8), pressure plate (9), pad (1), static ring (11), moving ring (12), moving ring rubber support (13), throat hoop (14), the flange (8) presses the corrugated pipe compensator (7) on the tank body, the corrugated pipe compensator (7) has a static ring (11) at the rear, and the static ring (11) and the dynamic ring (12) Contact, the moving ring (12) is set on the shaft head through the moving ring rubber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com