Regulating valve for proportioning air and fuel gas

A proportional control valve, gas technology, applied in the direction of diaphragm valve, multi-way valve, safety valve, etc., can solve the problems of non-proportional adjustment, troublesome use, low adjustment accuracy, etc., and achieve the effect of improving the use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

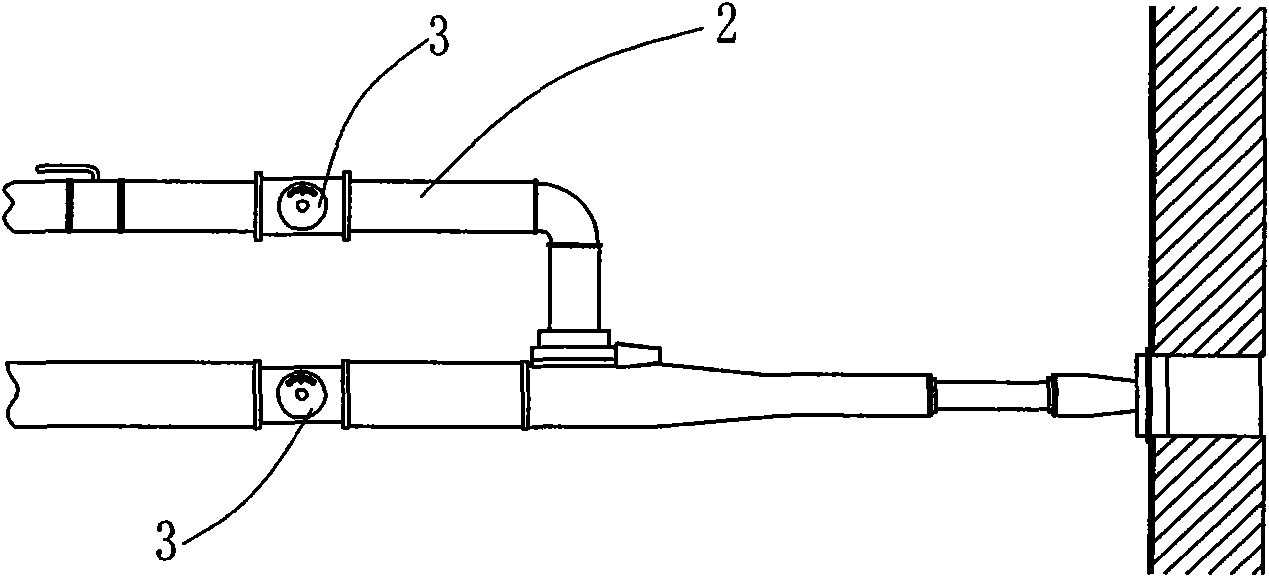

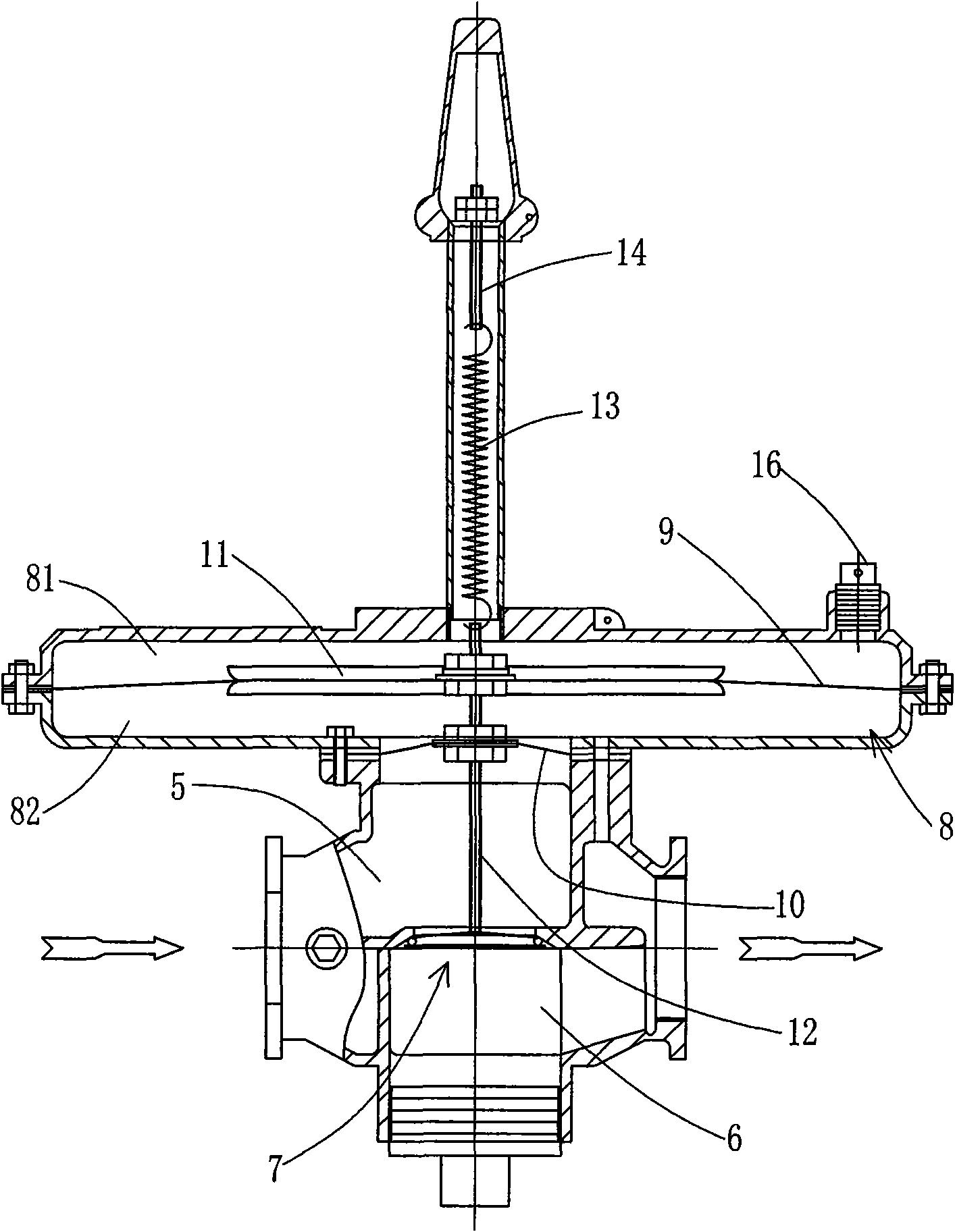

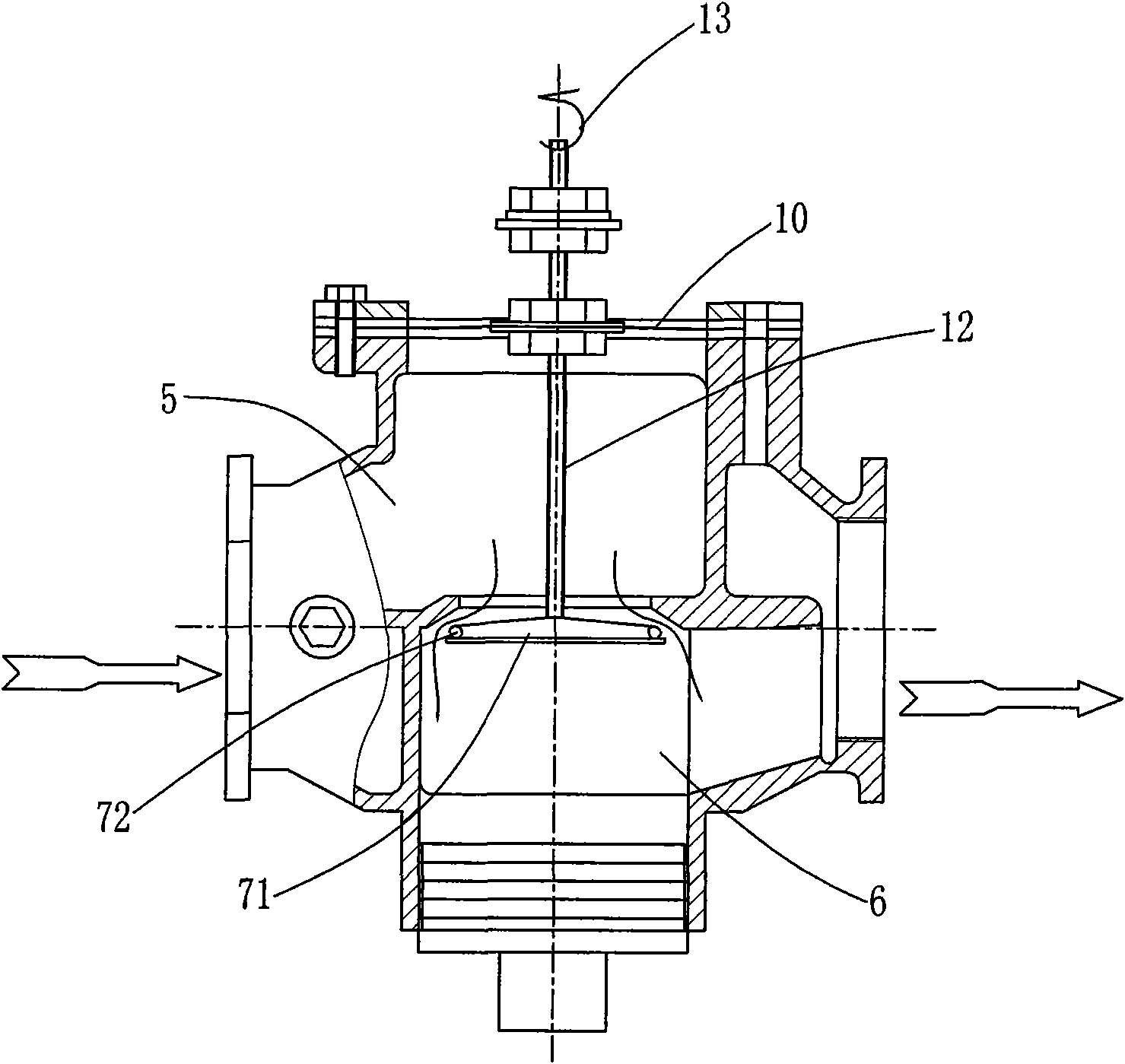

[0025] Example 1: Combining Figure 4 In this embodiment, the regulating valve 1 is installed on the gas pipeline 2, and a butterfly valve 3 is installed on the air pipeline. When the butterfly valve is opened, the combustion-supporting air and the gas are mixed in the suction-type proportional mixer 4, and a negative gas will be generated on the gas pipeline at the outlet end of the regulating valve. pressure, causing the regulating valve to open at the same time. combine figure 2 , 3 , the valve body base of the regulating valve is connected to the gas pipeline 2, and the valve body base has two chambers, that is, the upper chamber 5 connected to the gas inlet, and the lower chamber 6 connected to the gas outlet, and there is a gap between the upper and lower chambers. Valve plate 7, the body of the valve plate is a valve core aluminum disc 71, a valve core sealing ring 72 is sleeved on the outer periphery of the valve core aluminum disc, and the shell wall around the thr...

Embodiment 2

[0029] Example 2, combined with figure 2 , 5 , the regulating valve of this embodiment is also installed on the gas pipeline, and the nozzle mixer 15 will not generate suction to cause negative pressure in the gas pipeline at the outlet end of the regulating valve. The structural difference between this embodiment and the regulating valve in Embodiment 1 is that a feedback hole 16 is opened on the housing of the upper induction chamber 5, and the two ends of the feedback pipe 17 are connected to the feedback hole 16 and the air duct respectively.

[0030] In use, when the butterfly valve 3 on the air pipeline is opened, the combustion-supporting air enters the nozzle mixer 15, and at the same time, the air enters the upper induction chamber 81 of the regulating valve through the feedback pipe 17, and generates downward pressure on the pulse diaphragm 9, and the pulse The diaphragm drives the connecting rod 12 to overcome the tension of the tension spring 13 to go down, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com