Computer-control polishing method based on removal function prediction model

A function model and prediction model technology, applied in electrical program control, surface polishing machine tools, grinding/polishing equipment, etc., can solve problems such as difficulty in ensuring high convergence certainty, reducing processing efficiency, and difficulty in correction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

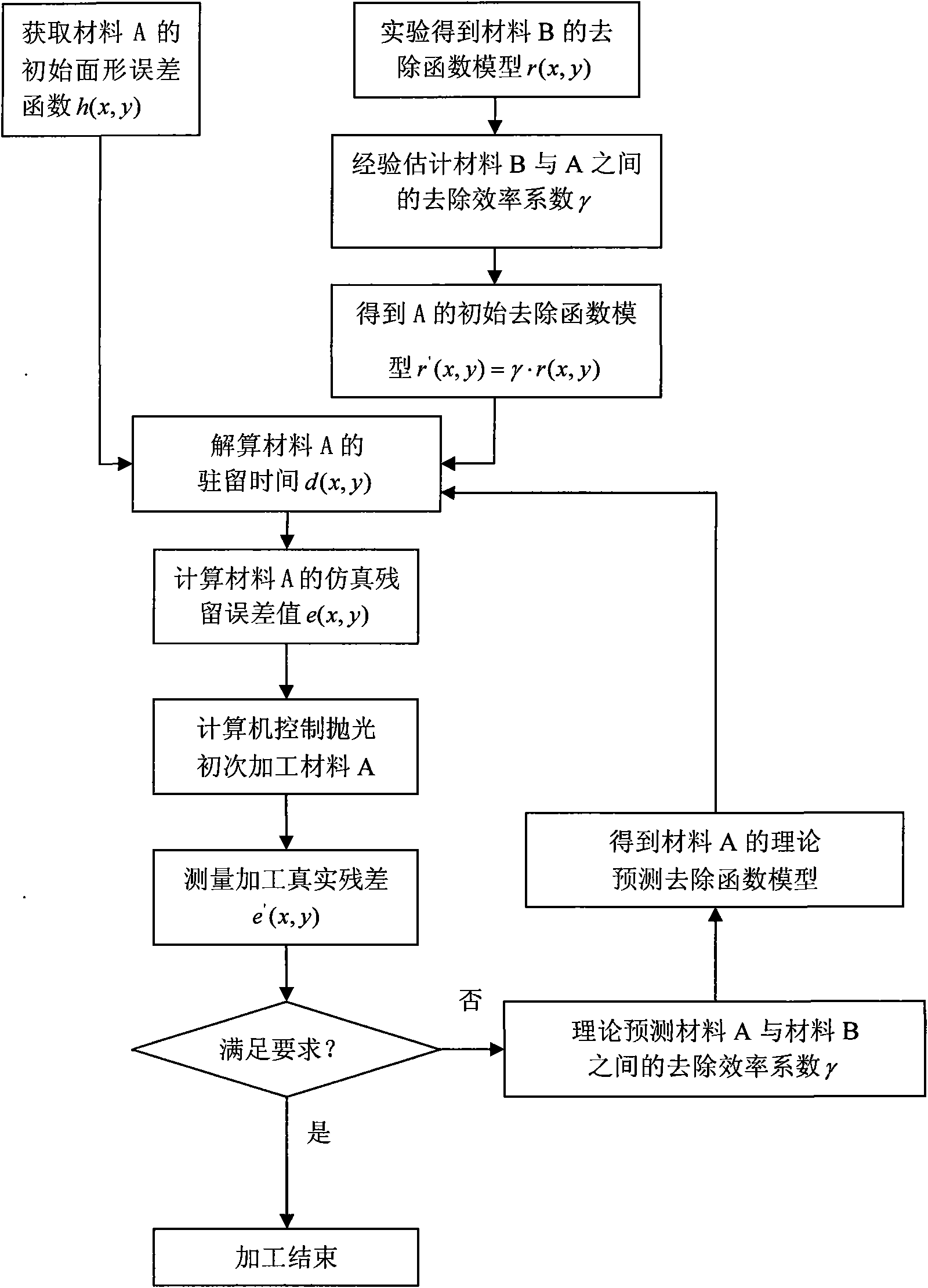

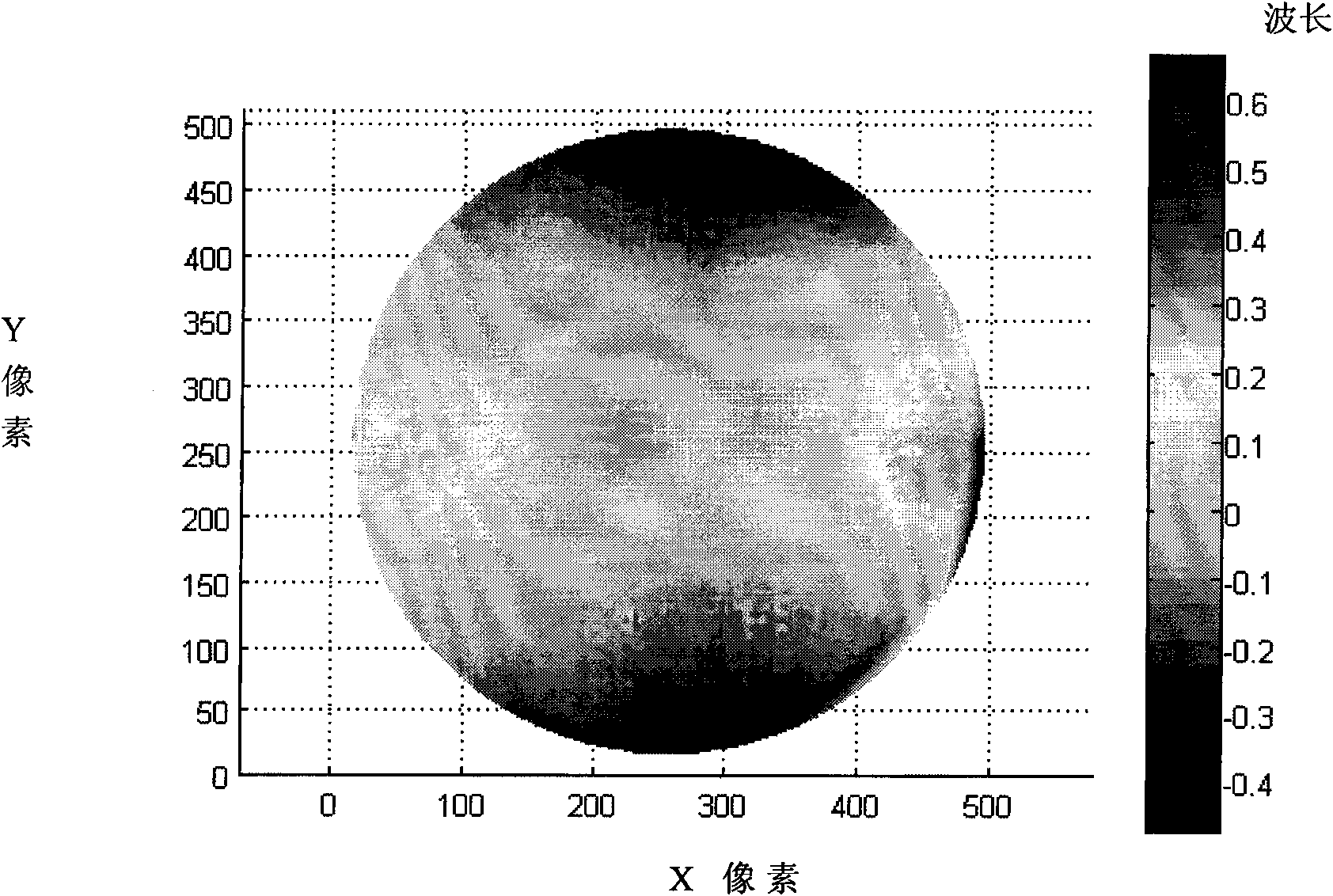

[0040] Such as figure 1 Shown, the present invention is based on the computer-controlled polishing method of removal function prediction model, and its steps are:

[0041] (1) The first computer-controlled polishing of unknown material A through known material B;

[0042] (2) The removal function model of theoretical prediction material A;

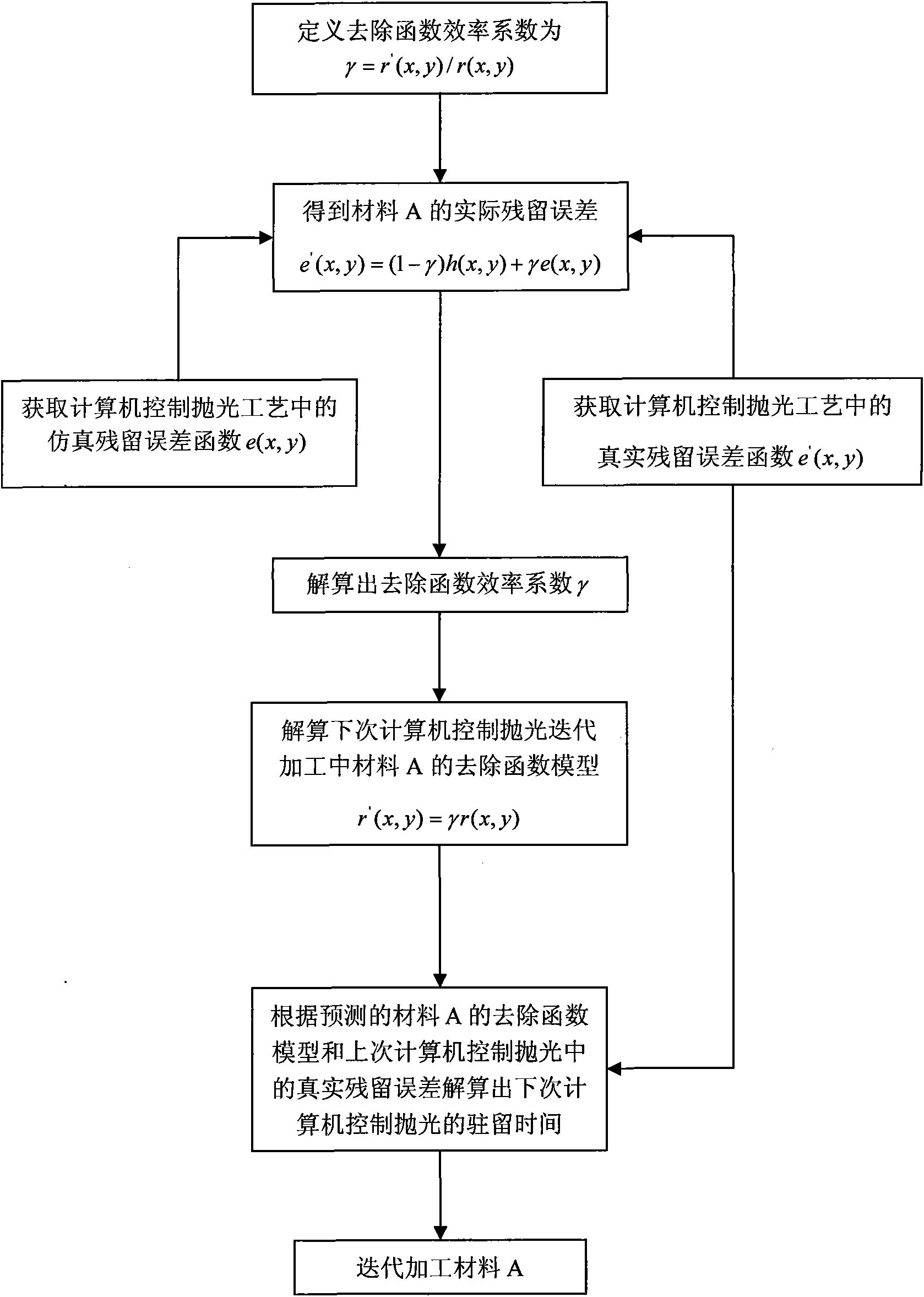

[0043] (3) Based on the predicted removal function model in step (2), the identification of the efficiency coefficient of the removal function model is introduced in the following computer-controlled polishing process. .

[0044] The theoretical basis of material removal in the computer-controlled polishing method is the Preston equation. When the processing parameters are constant, the material removal amount on the surface of the optical part can be expressed as a two-dimensional convolution of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com