Light-emitting diode chip packaging structure by using deposition method and manufacturing method thereof

A technology of chip packaging structure and light-emitting diodes, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve problems such as uneven distribution, inconvenience, and inconsistent color of white light source, achieving simple manufacturing process, Avoid shortening the luminous efficiency and life, and the effect of good product light properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

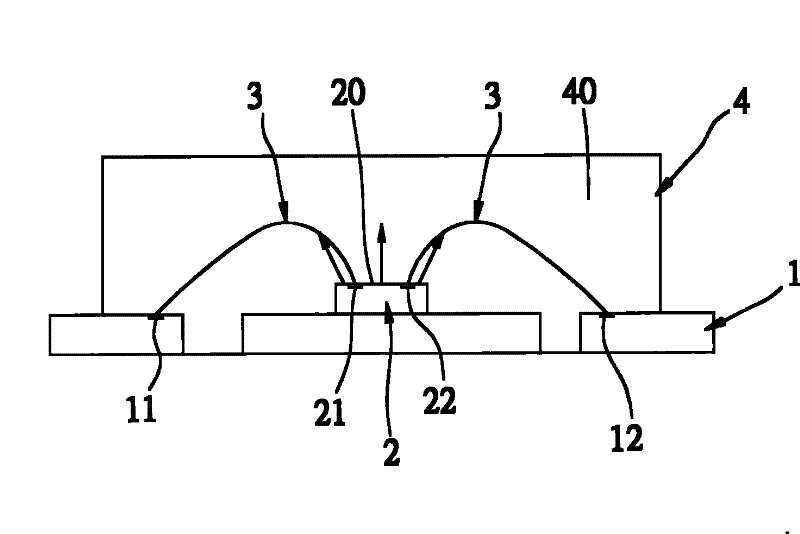

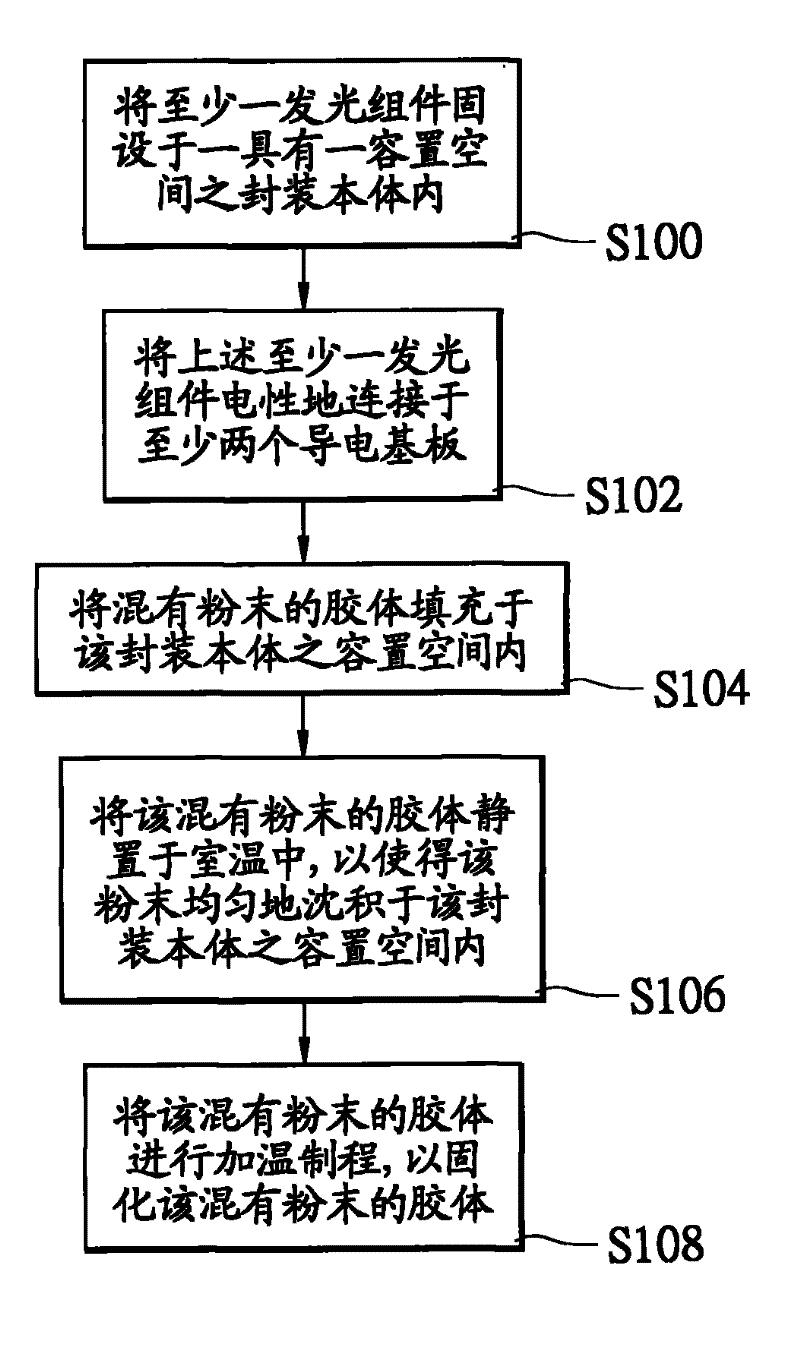

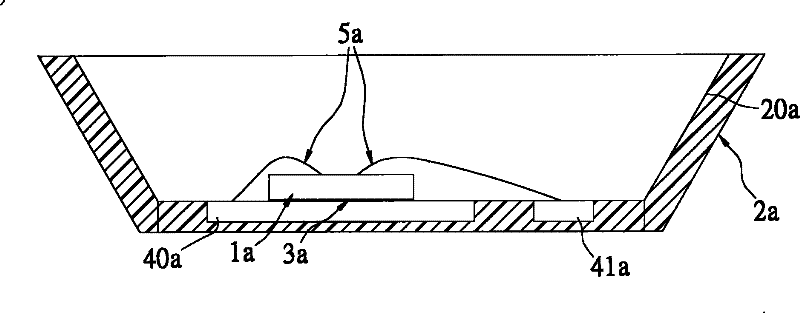

[0065] see figure 2 ,and Figure 2A to Figure 2C shown, where figure 2 It is a flow chart of the first embodiment of the manufacturing method of the light emitting diode chip packaging structure using the deposition method of the present invention; Figure 2A to Figure 2C Each is a schematic cross-sectional view of the first embodiment of the LED chip packaging structure using the deposition method of the present invention.

[0066] As can be seen from the above figures, the first embodiment of the present invention provides a method for manufacturing a light-emitting diode chip packaging structure using a deposition method, which includes the following steps:

[0067] Step S100: see figure 2 and Figure 2A As shown, at least one light-emitting component 1a is fixed in a package body 2a having an accommodating space 20a. Taking the first embodiment as an example, the above-mentioned at least one light-emitting component 1a is a blue light-emitting diode chip, and the pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com