Cu-ni-si-based alloy for electronic material

A technology of electronic materials and copper alloys, applied in conductive materials, conductive materials, metal/alloy conductors, etc., to achieve the effect of improving strength and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

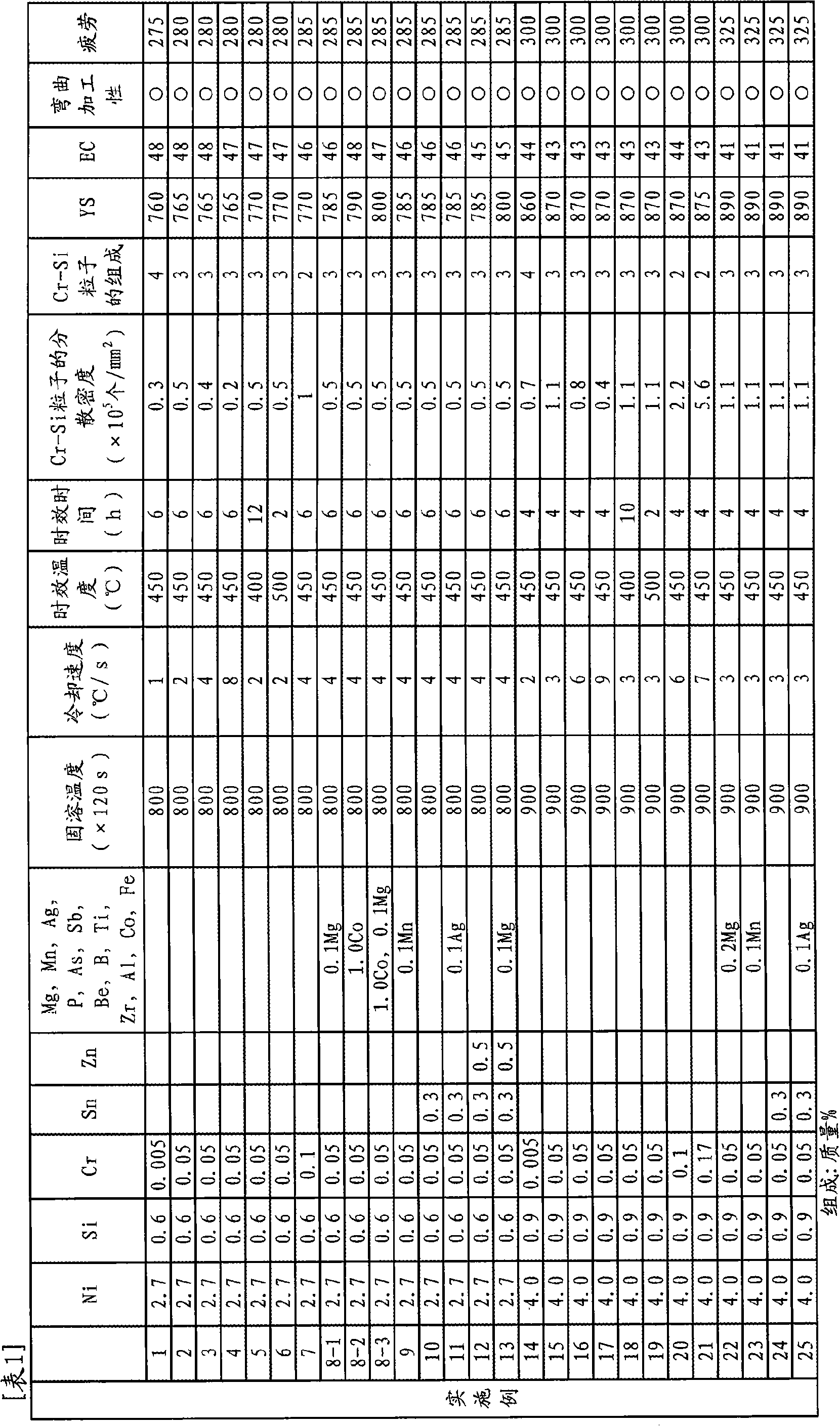

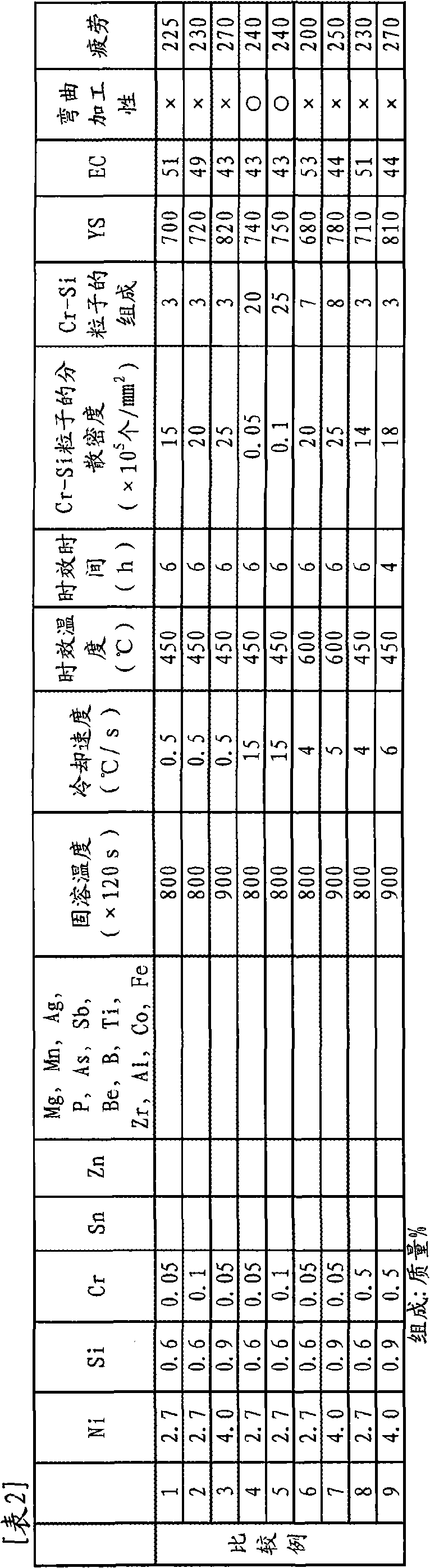

[0052] Specific examples of the present invention will be described below, but these examples are provided for further understanding of the present invention and its advantages, and are not intended to limit the invention.

[0053] The copper alloy used in the examples of the present invention has a composition in which Sn, Zn, Mg, Mn, Co, and Ag are appropriately added to copper alloys in which the contents of Ni, Si, and Cr are slightly changed as shown in Table 1. In addition, the copper alloys used in the comparative examples are Cu—Ni—Si alloys having parameters outside the range of the present invention.

[0054] Copper alloys having various compositions described in Table 1 were melted at a temperature of 1300° C. in a high-frequency melting furnace, and cast into ingots having a thickness of 30 mm. Then, after heating this ingot at a temperature of 1000° C., it was hot-rolled to a plate thickness of 10 mm, and then rapidly cooled. In order to remove scale on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com