Curved surface finishing processing device

A finishing and surface processing technology, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve problems such as low production efficiency, poor grinding quality, time-consuming and labor-intensive grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

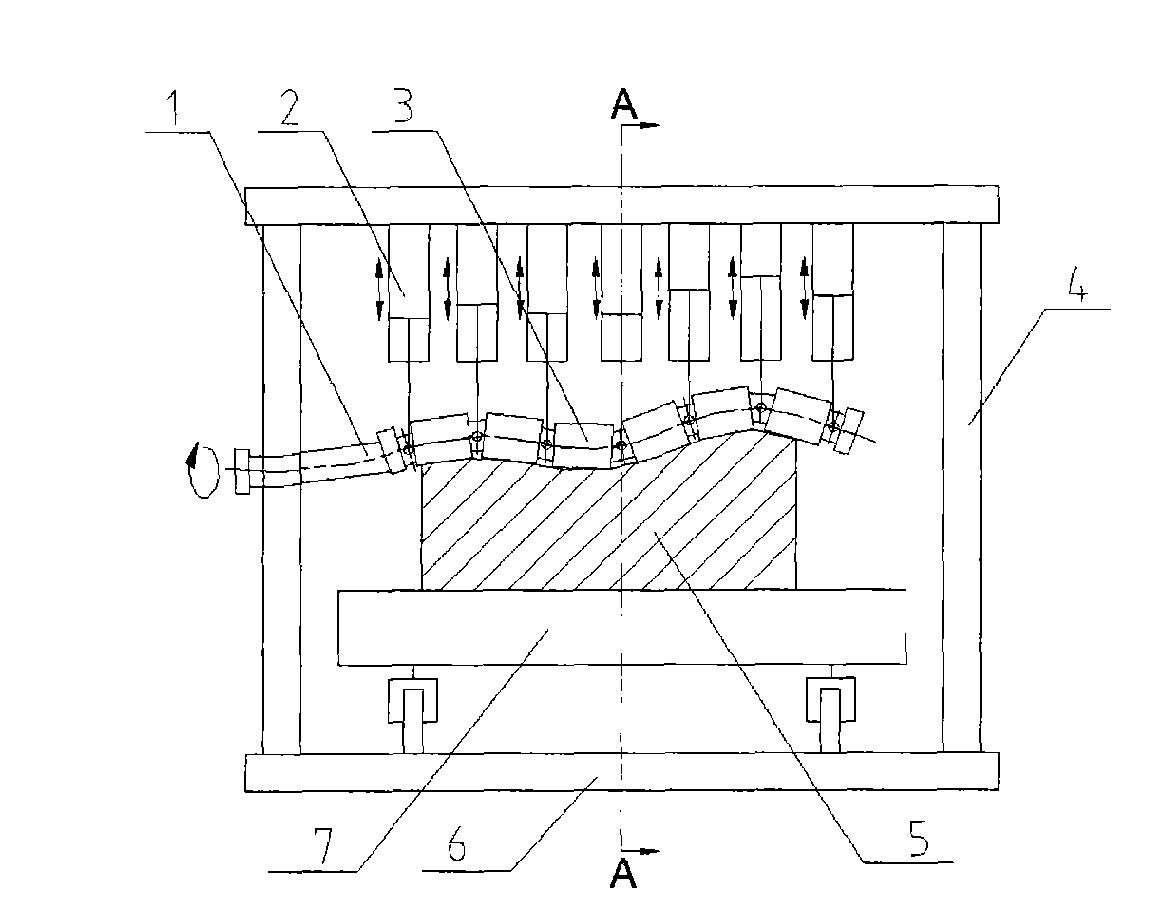

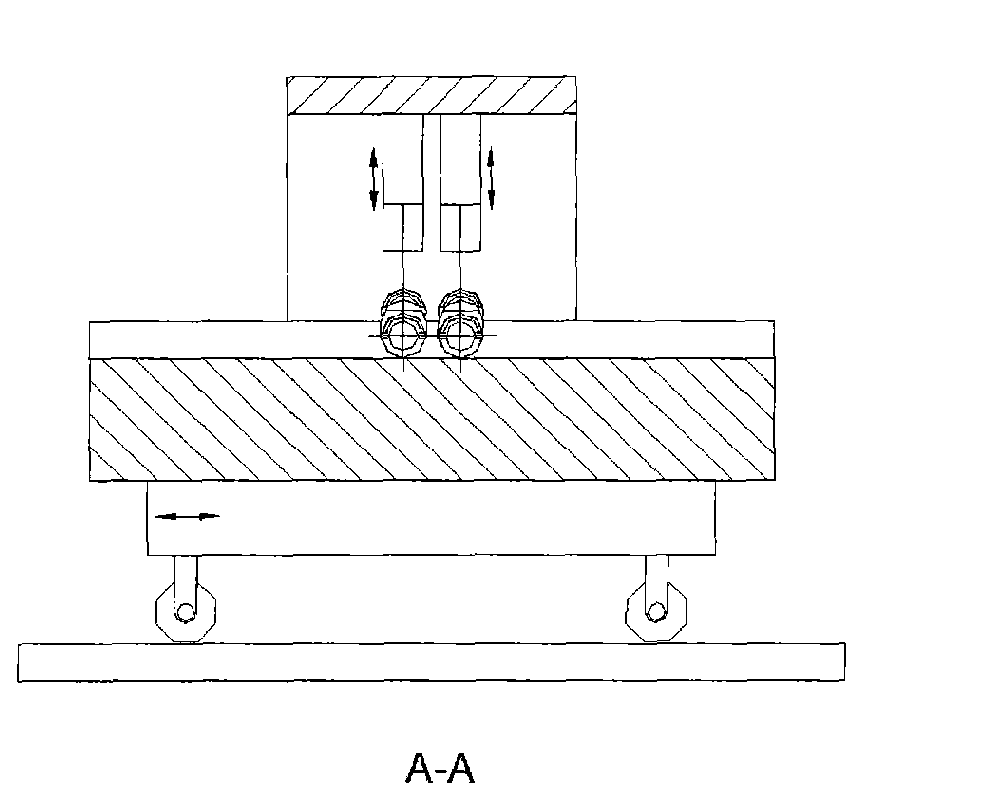

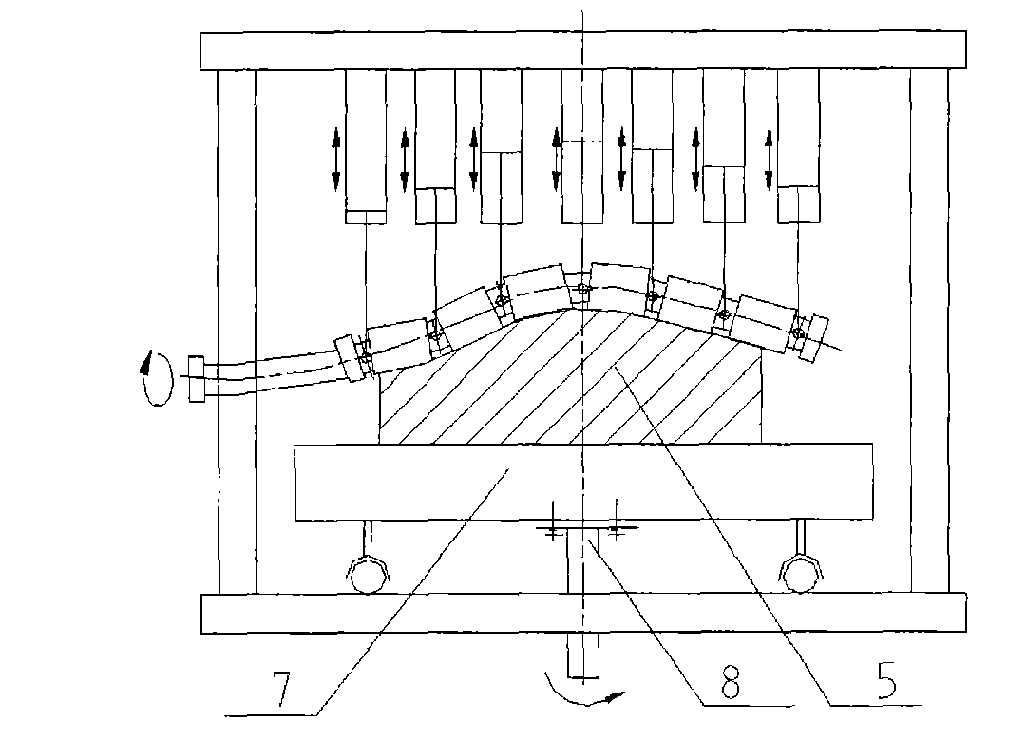

[0021] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0022] The curved surface finishing device is composed of a flexible shaft, a flexible shaft support mechanism, surface processing tools, a bracket, a base and a worktable. The flexible shaft is driven by a motor to rotate, and the axis of the flexible shaft can be passively bent along with the surface of the workpiece to be processed.

[0023] The flexible shaft is composed of one or several kinds of elastic elements such as steel wire, flexible shaft, steel wire rope, coil spring, polyurethane rubber, etc., and can also be composed of several rigid short shafts. Joint connection, the height and swing angle of the rigid short shaft can be changed. Several support mechanisms are arranged on the flexible shaft or the rigid short shaft. When the flexible shaft interacts with the surface of the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com