Washed-out sand machine

An abrasive belt and sand washing technology, which is applied in the field of cleaning equipment for woodworking abrasive belts, can solve problems such as inability to reduce costs, high cleaning costs, and environmental pollution, and achieve cost savings and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

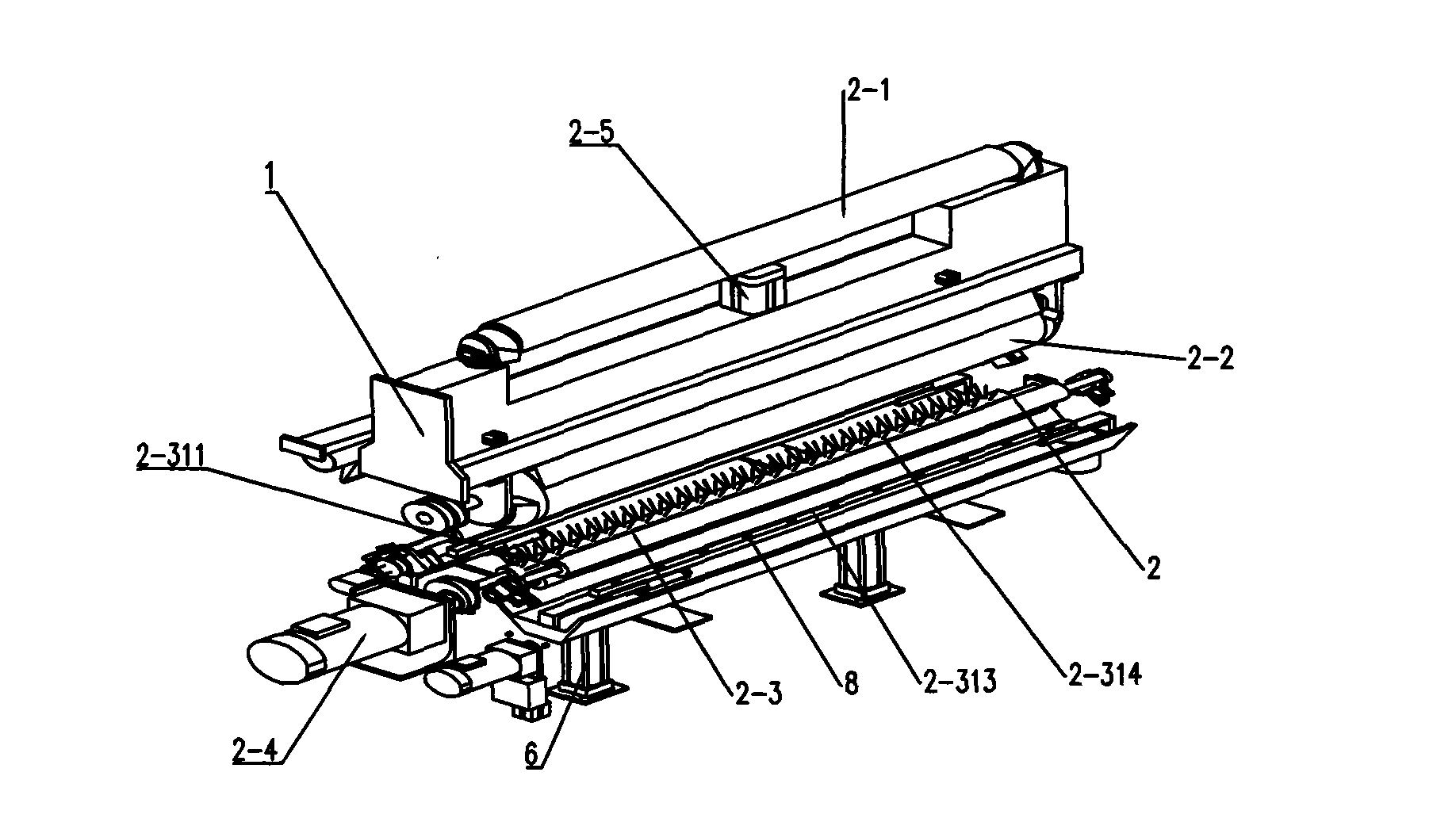

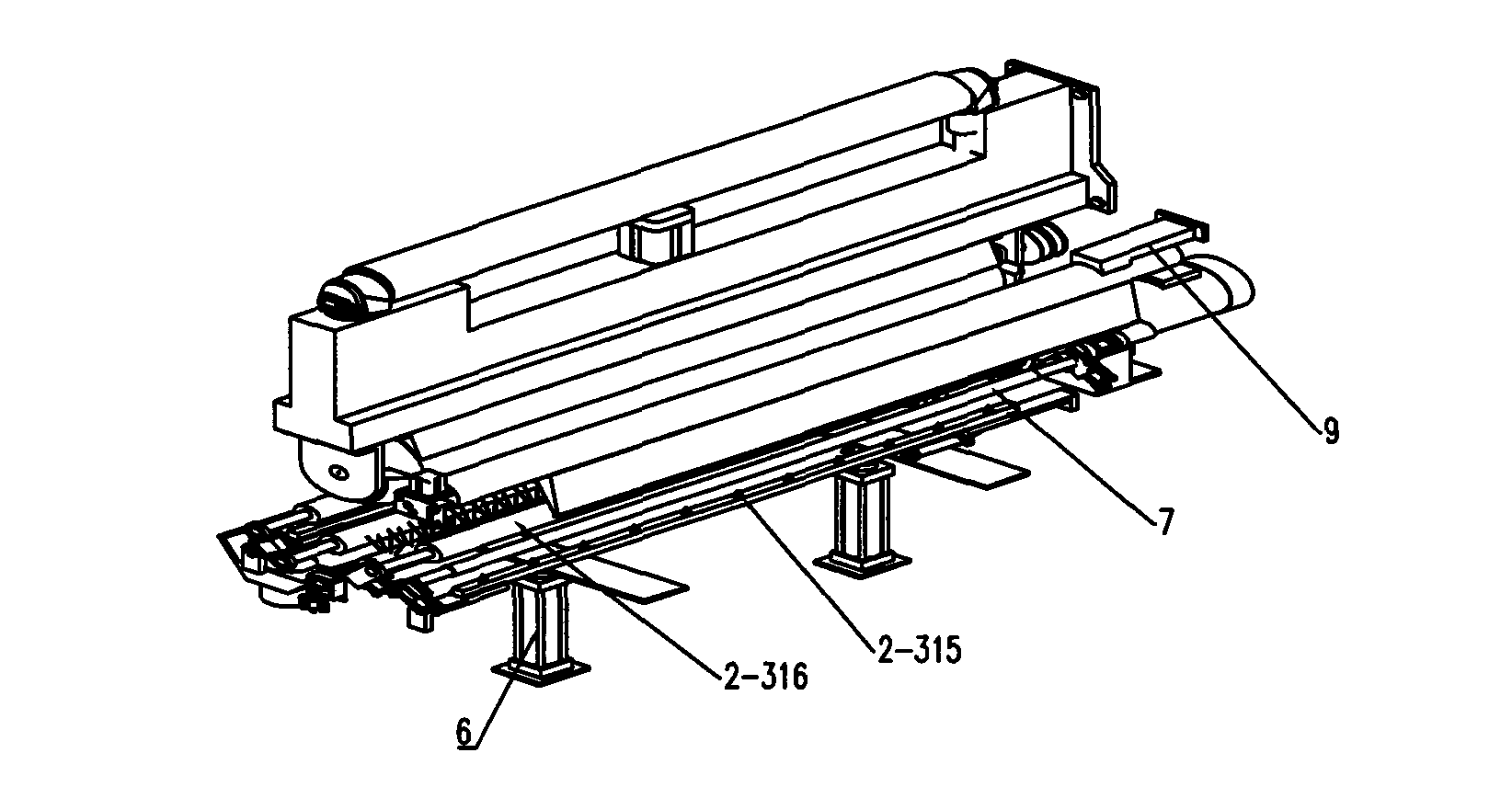

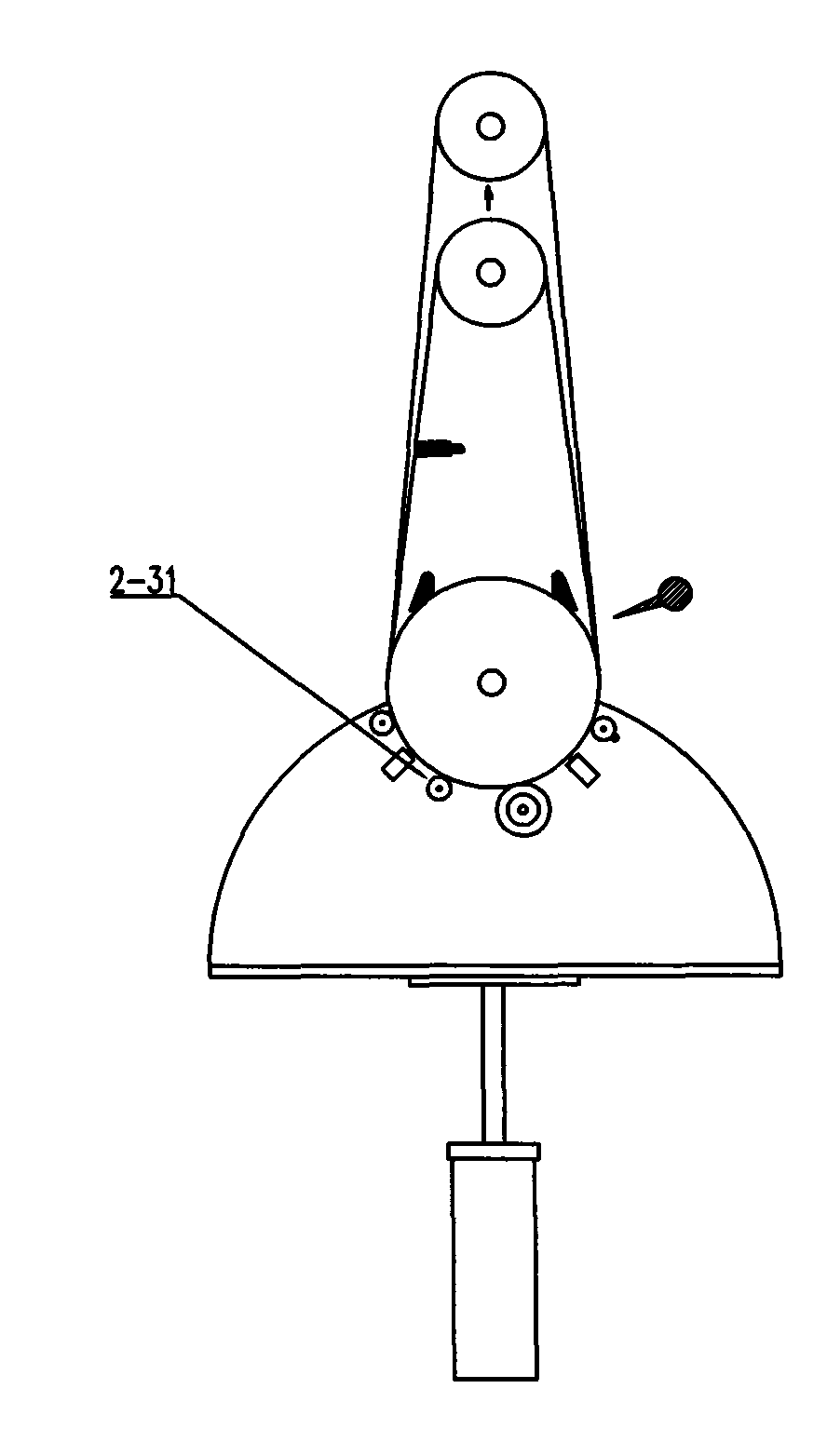

[0030] Such as Figure 1-7 Shown, a kind of abrasive belt washing machine of the present invention, it comprises frame 1, abrasive belt cleaning refurbishment device 2 and cleaning agent recovery filtering device 3, frame 1 is provided with the suspension shaft that places abrasive belt, abrasive belt cleaning and refurbishing device 2. It is mainly composed of upper and lower rubber rollers 2-1, 2-2 for installing abrasive belts, a roller brush cleaning device 2-3, and a power device 2-4 for driving various parts. The upper and lower rubber rollers 2-1, 2 Abrasive belt tensioning device 2-5 is arranged between -2, and a device for adjusting the length of the abrasive belt is arranged between the upper and lower rubber rollers 2-1 and 2-2, and the abrasive belt tensioning device between the two rubber rollers 2-5 is externally connected with a main control system, and its lifting height is set to several working length levels through the main control system. The roller brush ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com