Method for assembling tower by post-assembly rocker arm holding pole technology

A technology for holding poles and grouping towers, which is applied in the direction of towers, building types, buildings, etc., and can solve the problems that construction methods and tools cannot meet construction needs, large mobility, and enlarged engineering towers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0004] The best embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

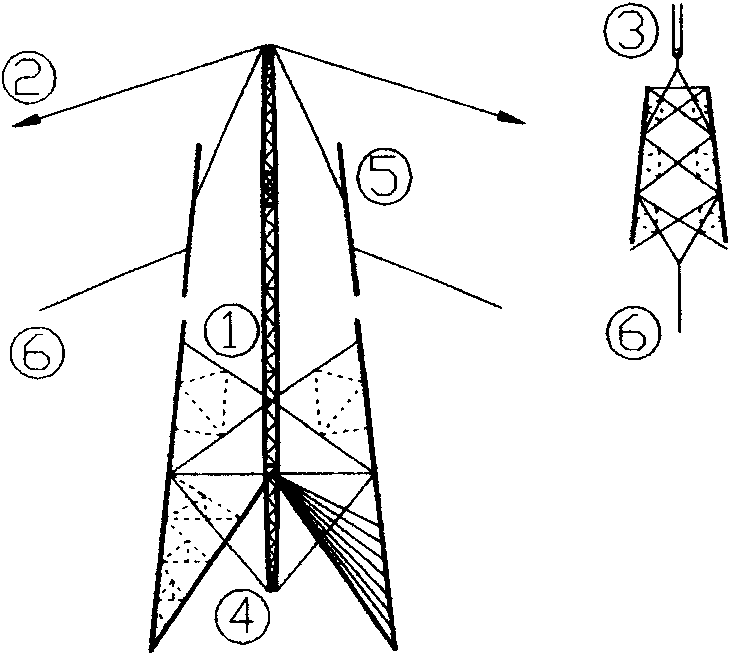

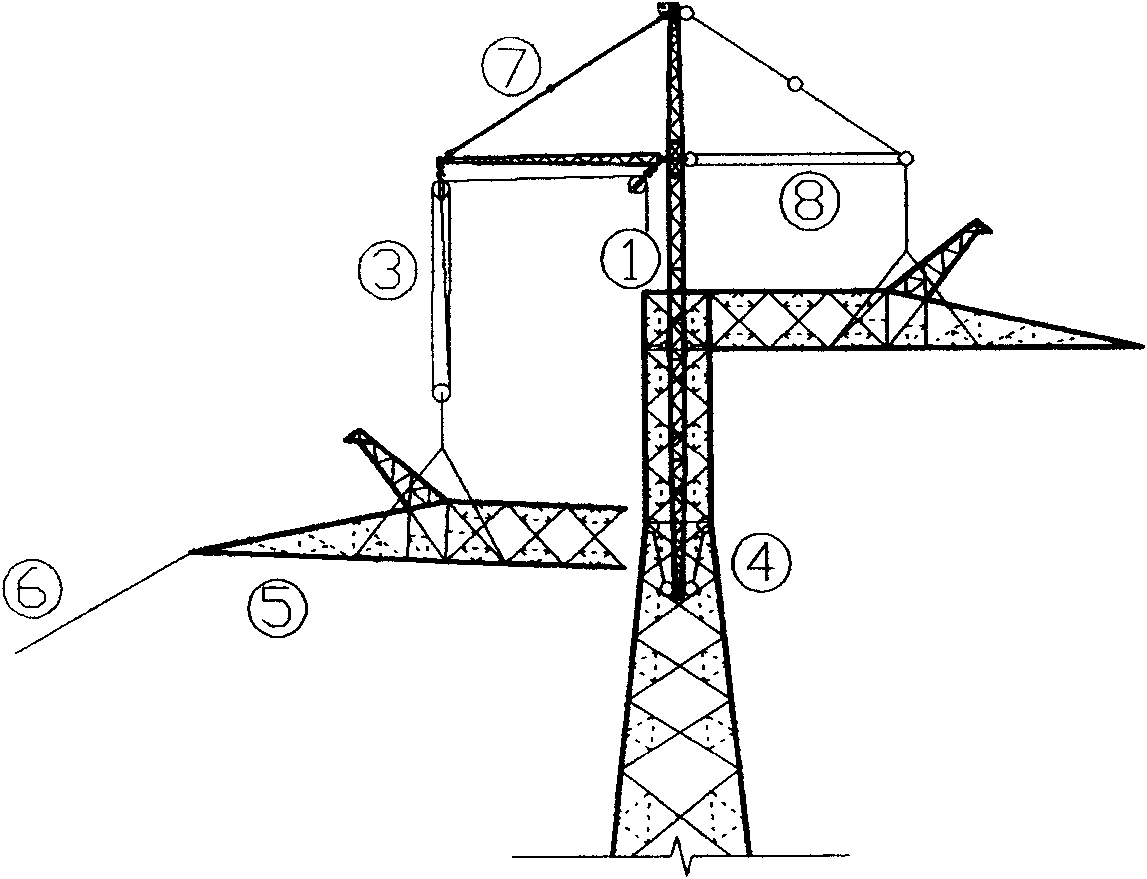

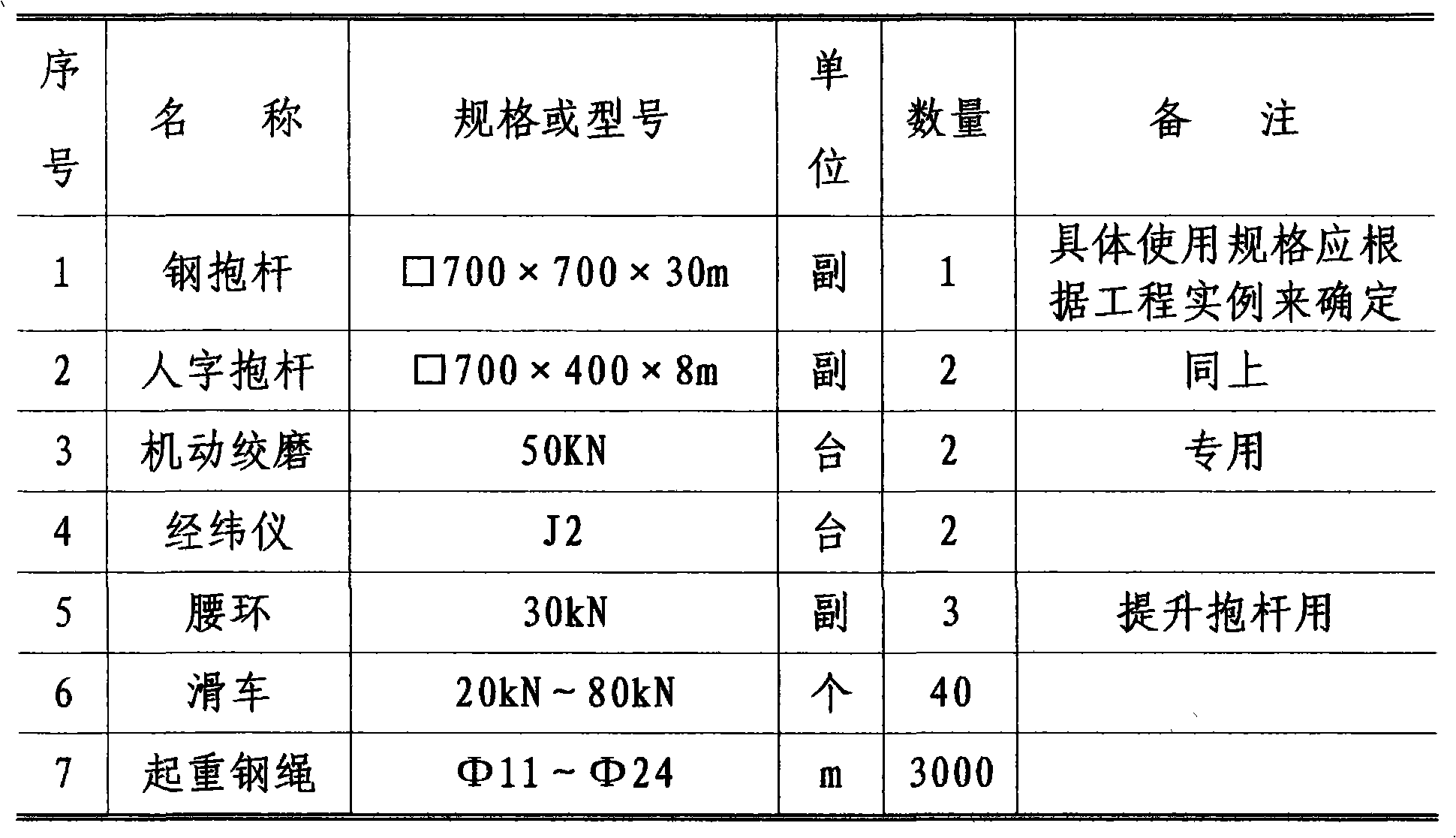

[0005] The method of post-assembly rocker arm holding pole technology is to hoist each section of the tower body separately with the outer pull wire holding pole (including the rocker arm seat section). The difference from the conventional method is that the rocker arm seat is pre-installed at the appropriate position of the arm holding pole. The position is set at the position where the top of the pole is downward and the length of the rocker arm is equal. After the hoisting of the tower body is completed, two pairs of rocker arms with a predetermined length are symmetrically assembled to hoist the tower head. According to the characteristics of the DC transmission tower, this method invented the rocker luffing system, which is to pre-determine the length of the rocker arm, the fixed-length luffing rod and the raising angle according to the center of gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com