Pipe connector

A technology of pipe joints and threaded joints, which is applied in the direction of pipes/pipe joints/fittings, passing elements, and sealing surfaces, which can solve problems such as corrosion, environmental damage, and increased production costs, and achieve cost reduction, no leakage of materials, and energy saving material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

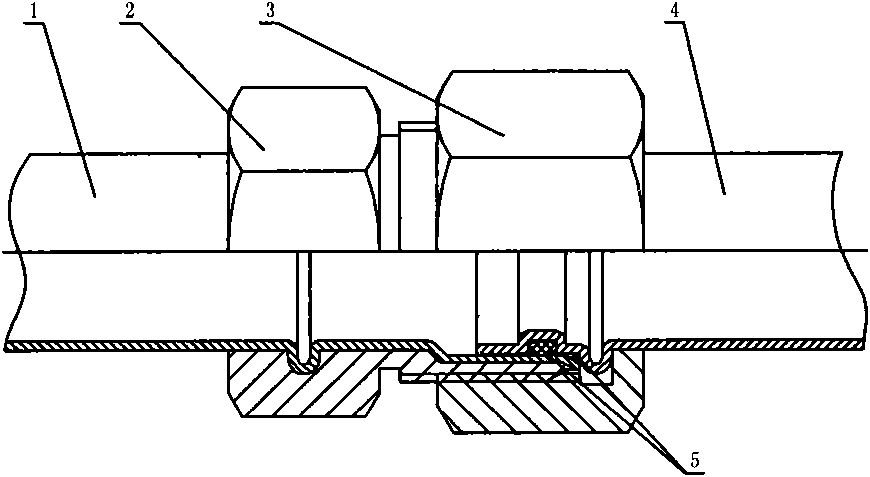

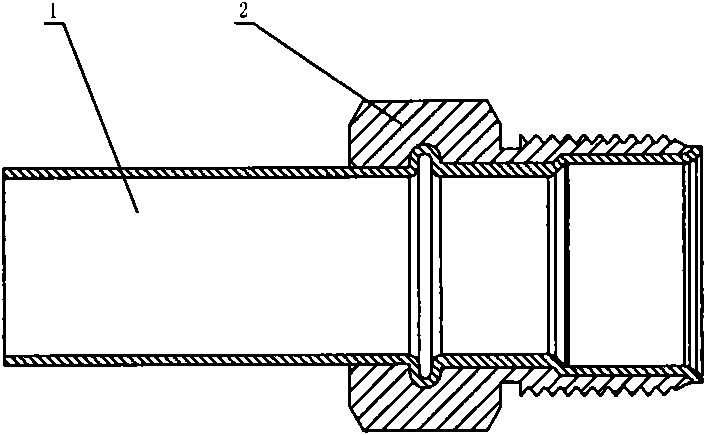

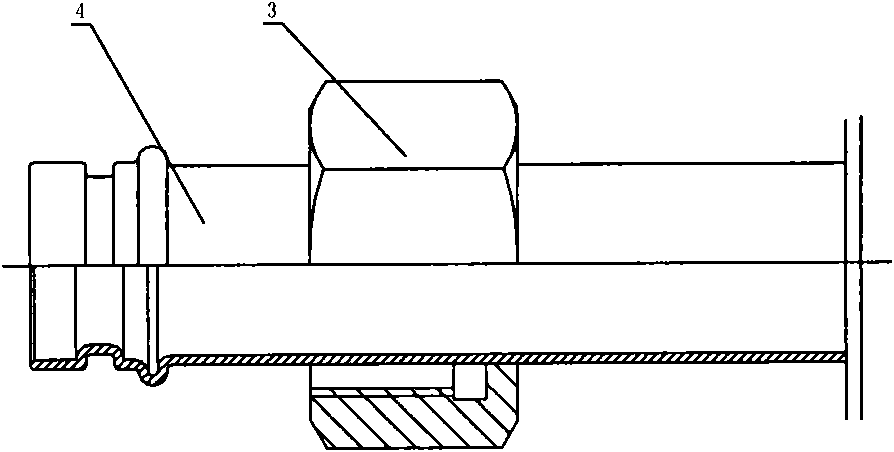

[0014] The connecting pipe A1 and the pipe B4 of the present invention include a threaded joint 2 provided with external threads and a nut 3 matched with the threaded joint 2. The threaded joint 2 is provided with an annular groove and a rotation stop groove, and the connecting end of the pipe A1 is provided with It is embedded in the annular boss in the annular groove of the threaded joint 2. The connecting end of the tube B4 is provided with an annular boss to prevent the tube B4 from falling off the nut 3, and the connecting port of the tube B4 is airtightly connected to the tube A1. In the present invention The annular bosses of tube A and tube B are formed by upsetting, riveting, diameter reduction, spinning and other processes. The air-tight connection section between the outer diameter of the tube B4 port and the inner diameter of the tube A1 port is provided with an annular groove, which is formed with the tube A1 A sealing ring 5 is provided in the radial space, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com