Method for detecting lubricating terminal of intermittent guide rail and lubricating device using same

A lubricating device, intermittent technology, applied in the direction of measuring device, engine lubrication, quantitative device, etc., can solve the problems of low oil supply pressure, no oil damage on the guide rail, and failure to find the problem of metering components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

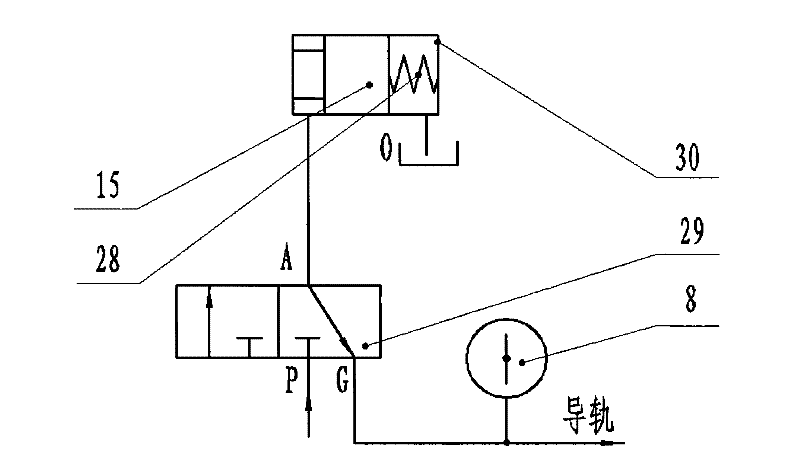

[0030] The terminal detection method of the intermittent guide rail lubrication of the present invention can perform terminal detection because it utilizes the pressure peak caused by sudden oil supply during the guide rail lubrication process and the pressure gradually decreases due to the gradual discharge of oil to the guide rail. The characteristic is that a pressure detection element for monitoring the pressure change of the output end is installed at the output end of the lubricating device connected with the oil pipe of the lubricating terminal, such as an electric contact pressure gauge. The pressure detection element can convert the voltage value into an electrical signal and output it to a corresponding control system for joint control with other actions. In addition to a visual pointer similar to ordinary pressure gauges, the electric contact pressure gauge also has two adjustable pointers, which can respectively send signals for the high pressure and low pressure co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com