Center beam tube type cable

A central beam tube and beam tube type technology, applied in the direction of fiber mechanical structure, etc., can solve problems such as poor pressure resistance, beam tube shrinkage, fiber breakage, etc., and achieve the effects of reducing its own weight, saving costs, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

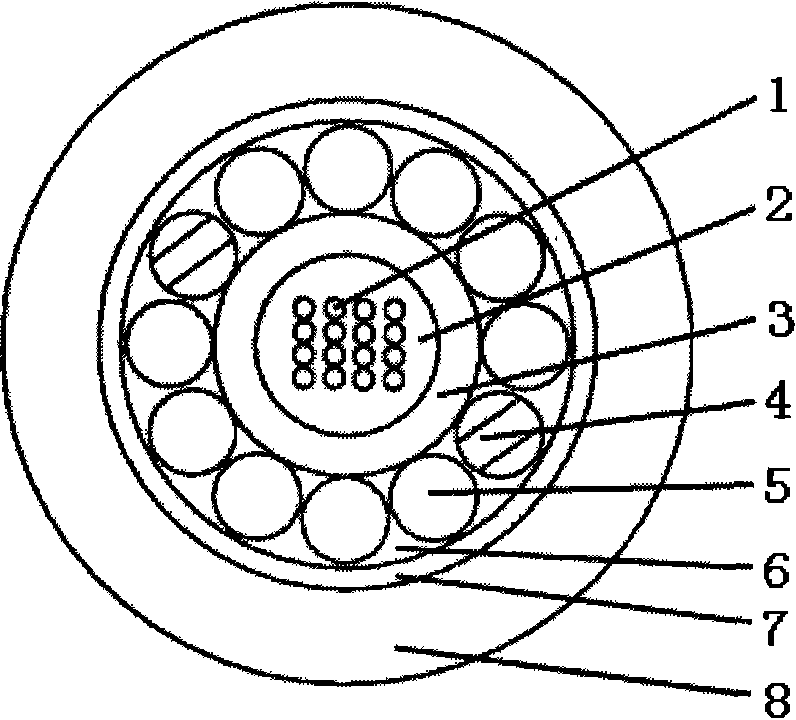

[0021] please see figure 1 , a central bundle tube type optical cable, which includes a circular central bundle tube 3, which contains an optical fiber 1 and an internal resistance water object 2, along the outer wall of the central bundle tube, centered on the axis of the central beam tube, extending longitudinally and in a single The reinforcing member 4 is covered with a helical direction or a clockwise / counterclockwise staggered direction, and the reinforcing member 4 is provided with a protective layer 7, and there is an external water blocking object 6 in the gap between the protective layer 7 and the central bundle tube to protect A sheath layer 8 is provided outside the layer 7; the characteristic is that the reinforcing member 4 contains at least ten filling pieces 5, and the filling pieces are symmetrically distributed outside the central bundle tube, and the pitch of the spiral is 300mm.

Embodiment 2

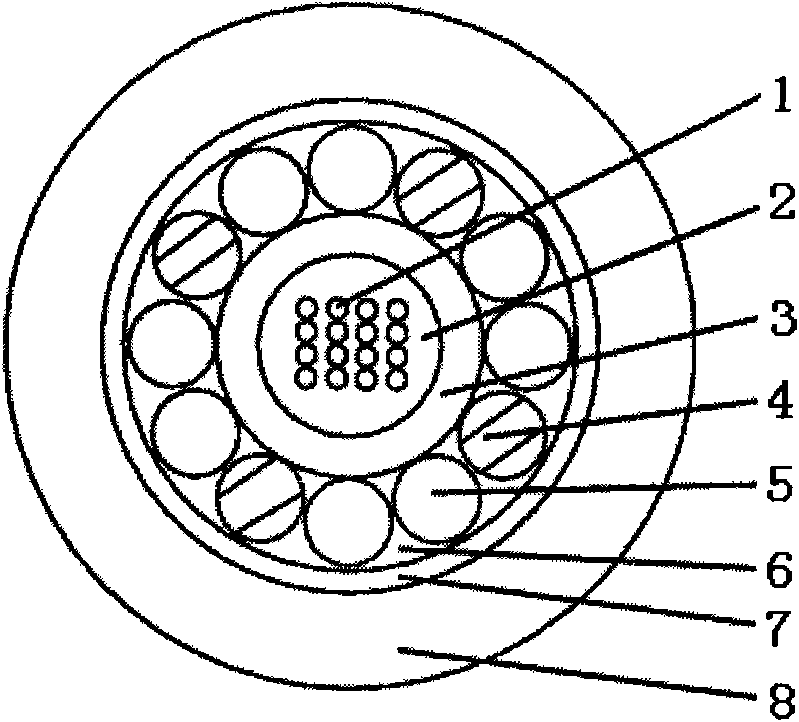

[0023] please see figure 2 , basically the same as the implementation example 1, the difference is that: the two filling pieces are replaced by reinforcing pieces; the filling pieces are also symmetrically distributed outside the central bundle tube.

Embodiment 3

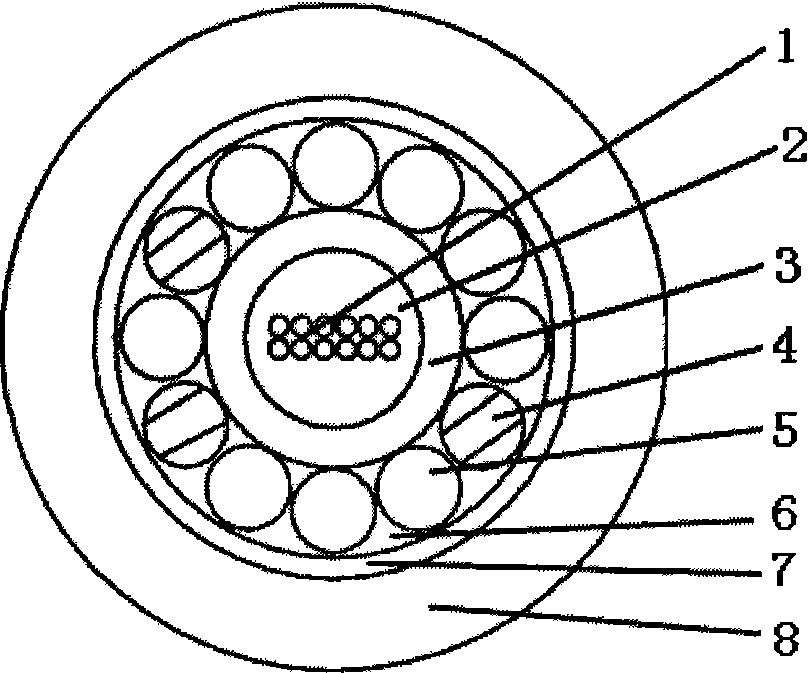

[0025] please see image 3 , basically the same as the implementation example 1, the difference is that: the number of optical fibers is changed from 16 to 12; one of the fillers is replaced by a reinforcement; the fillers are also asymmetrically distributed outside the central beam tube .

[0026] In the present invention, since the reinforcing member is in direct contact with the central bundle tube and tightly wrapped on the central bundle tube in a spiral manner, it effectively prevents the shrinkage of the central bundle tube when the temperature cycle changes, so that the optical fibers in the splice box will not be affected by temperature. Changes are easy to break; in addition, due to the inclusion of non-metallic fillers in the reinforcement, the weight of the optical cable is greatly reduced, and the requirements for the tower and its foundation are reduced. Therefore, the cost is greatly saved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Pitch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com