Tape sticking device

A gluing device and gluing technology, applied in the direction of sustainable manufacturing/processing, electrochemical generators, electrical components, etc., can solve the problems of occupying effective battery space, tension force cell pressure, waste tape, etc., to reduce Occupancy, stress reduction, adverse effects reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

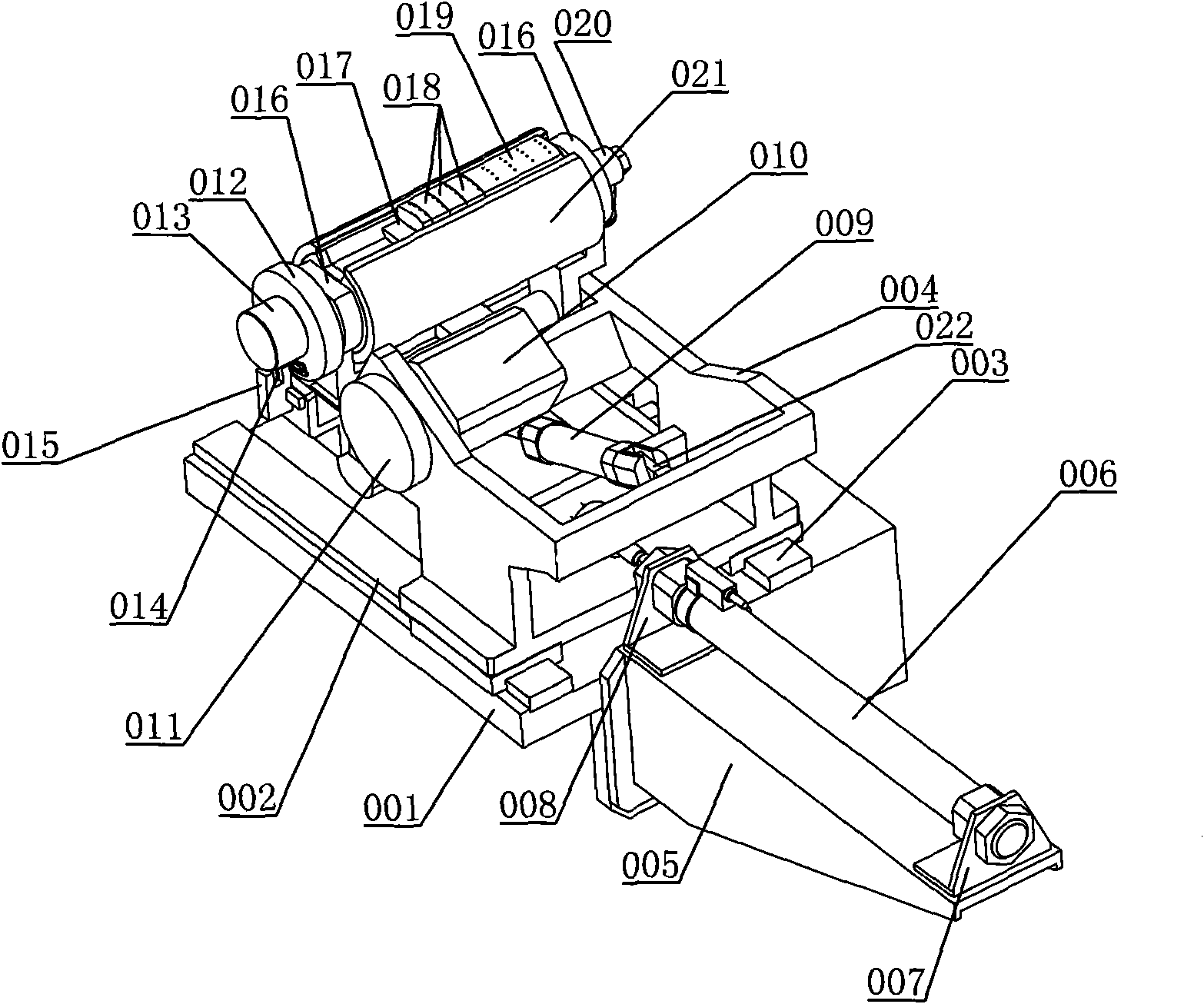

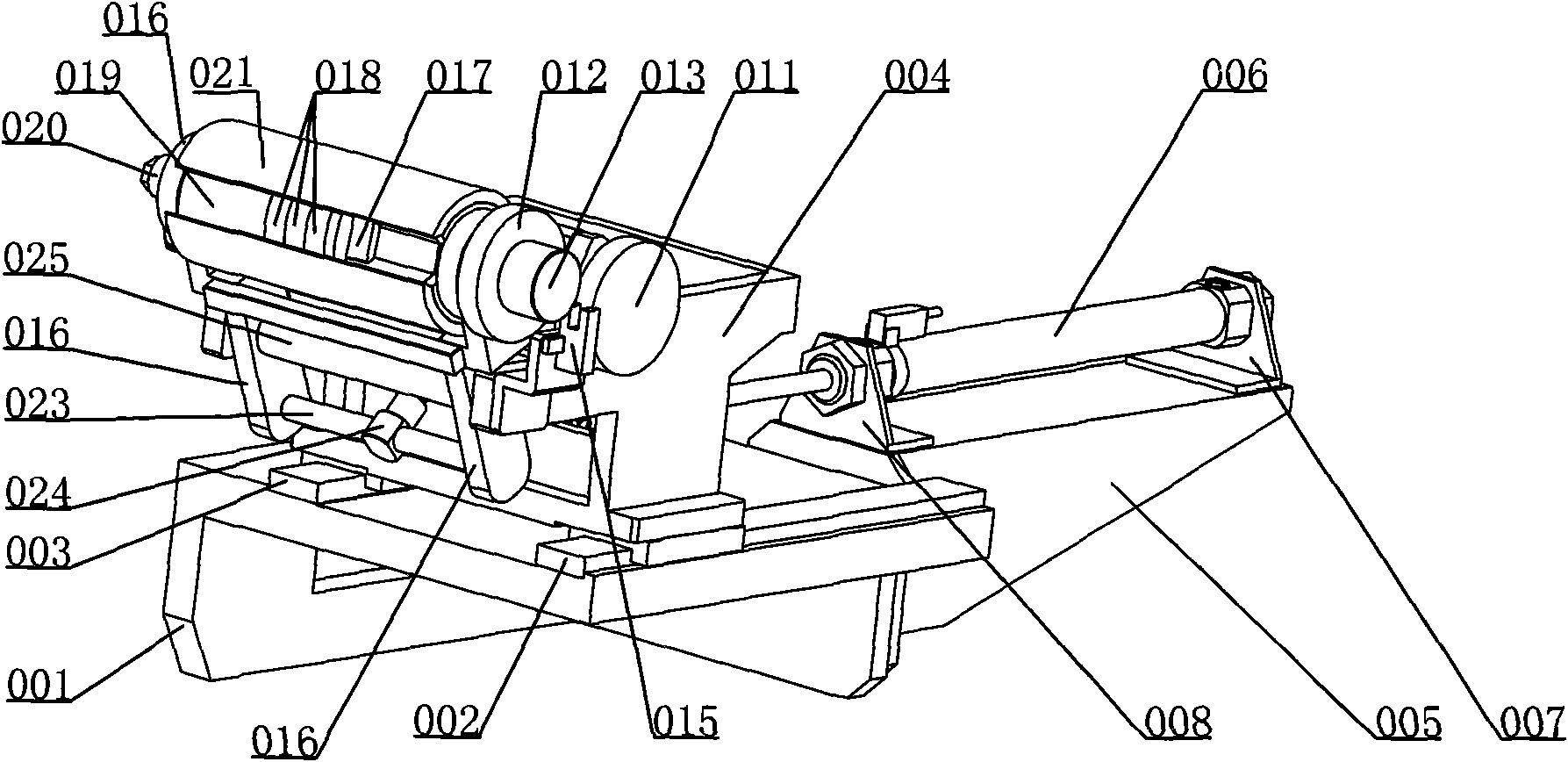

[0017] figure 1 and figure 2 A specific embodiment of the invention is shown.

[0018] like figure 1 and figure 2 As shown, the gluing device includes a control unit (not shown in the accompanying drawings), a mounting plate 001, a first guide rail 002, a second guide rail 003, a support frame 004, a cylinder mounting plate 005, a first cylinder 006 (that is, a drive support frame movement power mechanism), the first cylinder bracket 007, the second cylinder bracket 008, the second cylinder 009, the servo motor 010, the first friction wheel 011, the second friction wheel 012, the gland 013, the induction plate 014, the sensor 015 , swing arm 016, stopper 017, movable rubber suction block 018, fixed rubber suction block 019, vacuum suction joint 020, rubber sticking roller 021, cylinder installation block 022, pull rod 023, cylinder connection block 024 and connecting shaft 025. The servo motor 010, the first friction wheel 011 and the second friction wheel 012 constitute...

Embodiment 2

[0022] Embodiment 1 can also be simplified to obtain Embodiment 2: the swing frame and the second cylinder 009 are removed, and the gluing roller 021 is directly pivotally connected to the supporting frame 004 .

[0023] When working, the piston rod of the first cylinder 006 retracts, the support frame 004 returns to the glue suction position, and the movable glue suction block 018 and the fixed glue suction block 019 are located directly below the adhesive tape (the positions of the sensor 015 and the induction piece 014 correspond to each other) ; If the adhesive roller 021 is not at the angle corresponding to the positions of the sensor 015 and the induction sheet 014, the servo motor 010 works until the induction occurs between the sensor 015 and the induction sheet 014, and the control unit controls the servo motor 010 to stop according to the signal of the sensor 015, At this time, the movable glue-absorbing block 018 and the fixed glue-absorbing block 019 are directly be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com