A kind of processing method of catfish luncheon meat

A processing method and technology for luncheon meat, which are applied in fish processing, slaughtering, food preparation, etc., can solve the problems of unreasonable processing methods and technological conditions, affecting the promotion and consumption of catfish products, and poor product color and flavor, and achieve emulsification. Good sex, less thorns, good oil retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

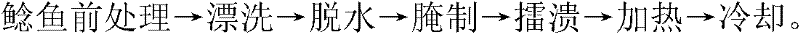

[0032] A processing method for catfish luncheon meat, the processing process comprising:

[0033] Pre-treatment: remove the viscera, skin and head of the catfish, and cut the fish meat into pieces after cleaning;

[0034] Rinse: rinse twice with 0.5% NaCl solution at 5-7°C;

[0035] Dehydration: Squeeze with gauze for dehydration;

[0036] Pickling: Pickle with pickling agent for 10 hours at 4°C; the ratio of pickling agent is 2% of salt, 0.3% of compound phosphate, 0.8% of glucose, 0.015% of nitrite, 0.04% of sodium ascorbate, and 0.03% of nicotinamide %.

[0037] Beating: Add spices to the marinated fish, and beat at 6°C for 6 minutes; the proportion of spices is 0.3% ginger powder, 0.1% white pepper powder, 0.1% clove powder, 0.4% monosodium glutamate, 1% sugar, and 1% soy sauce , rice wine 1%.

[0038] Heating: Put the surimi into a stainless steel mold after crushing, and cook at 85°C for 2.5 hours;

[0039] Cooling: cooling with cold water for 30 minutes to obtain t...

Embodiment 2

[0042] The processing method of catfish luncheon meat is with embodiment 1, and its rinsing is to use 0.5%NaHCO 3 solution, rinsed twice at 5-7°C; the pickling agent is 2.5% of salt, 0.4% of compound phosphate, 1.0% of glucose, 0.02% of nitrite, and 0.05% of sodium ascorbate; the proportion of spices is 0.4% of ginger powder , 0.2% white pepper powder, 0.2% clove powder, 0.6% monosodium glutamate, 1.2% sugar, 1% rice wine; catfish processing is through pretreatment of raw catfish → rinsing → dehydration → pickling → crushing → filling → vacuum sealing → high-pressure sterilization →Back pressure cooling and other processes to obtain canned catfish luncheon meat products of excellent quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com