Filtering medium for molten metal and method for producing the same

A filter medium and molten metal technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of fast formation of filter cake layer and insufficient transmittance, and achieve the effect of high inclusion removal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

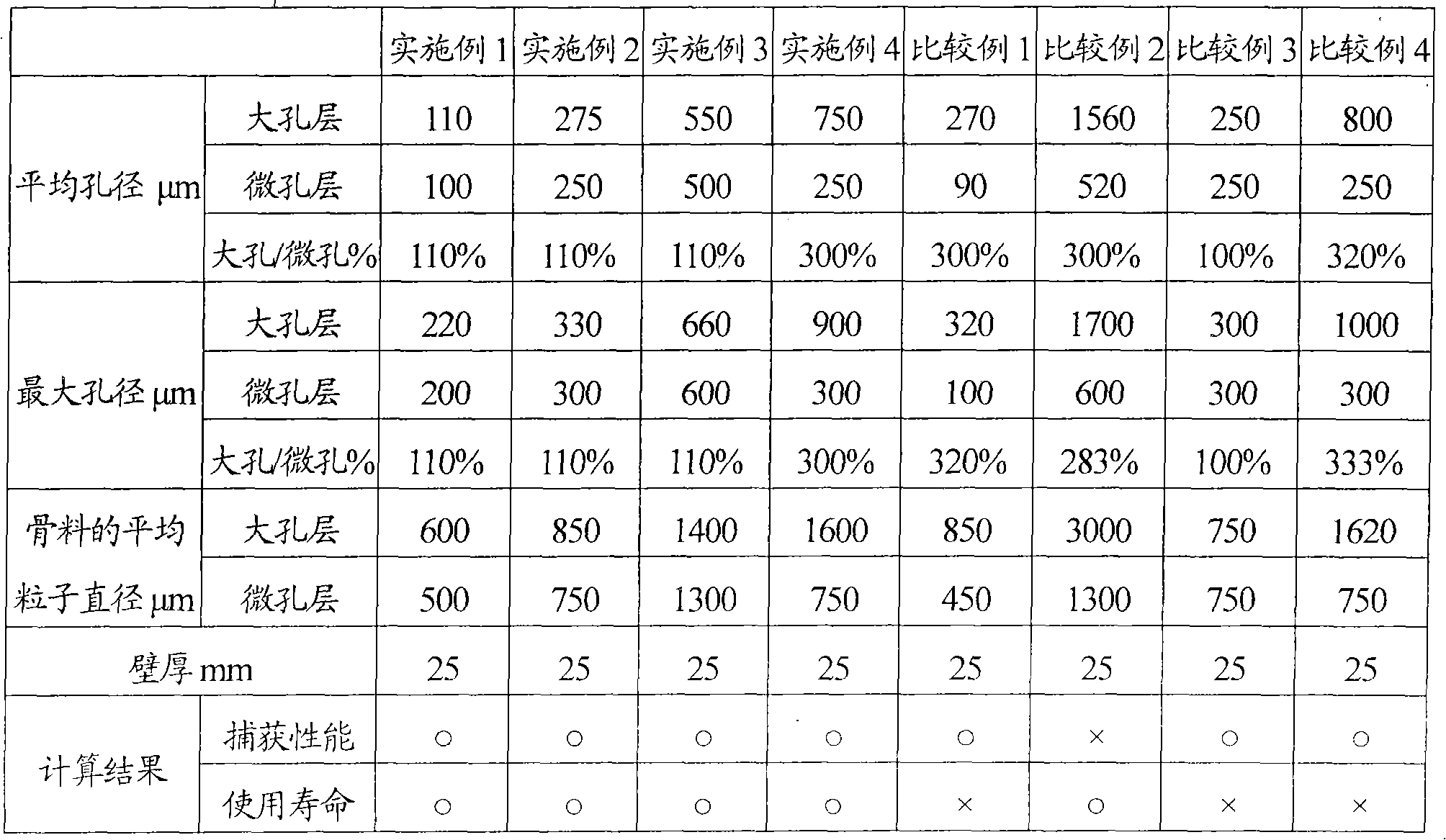

[0031] Examples and comparative examples of the present invention will be described below.

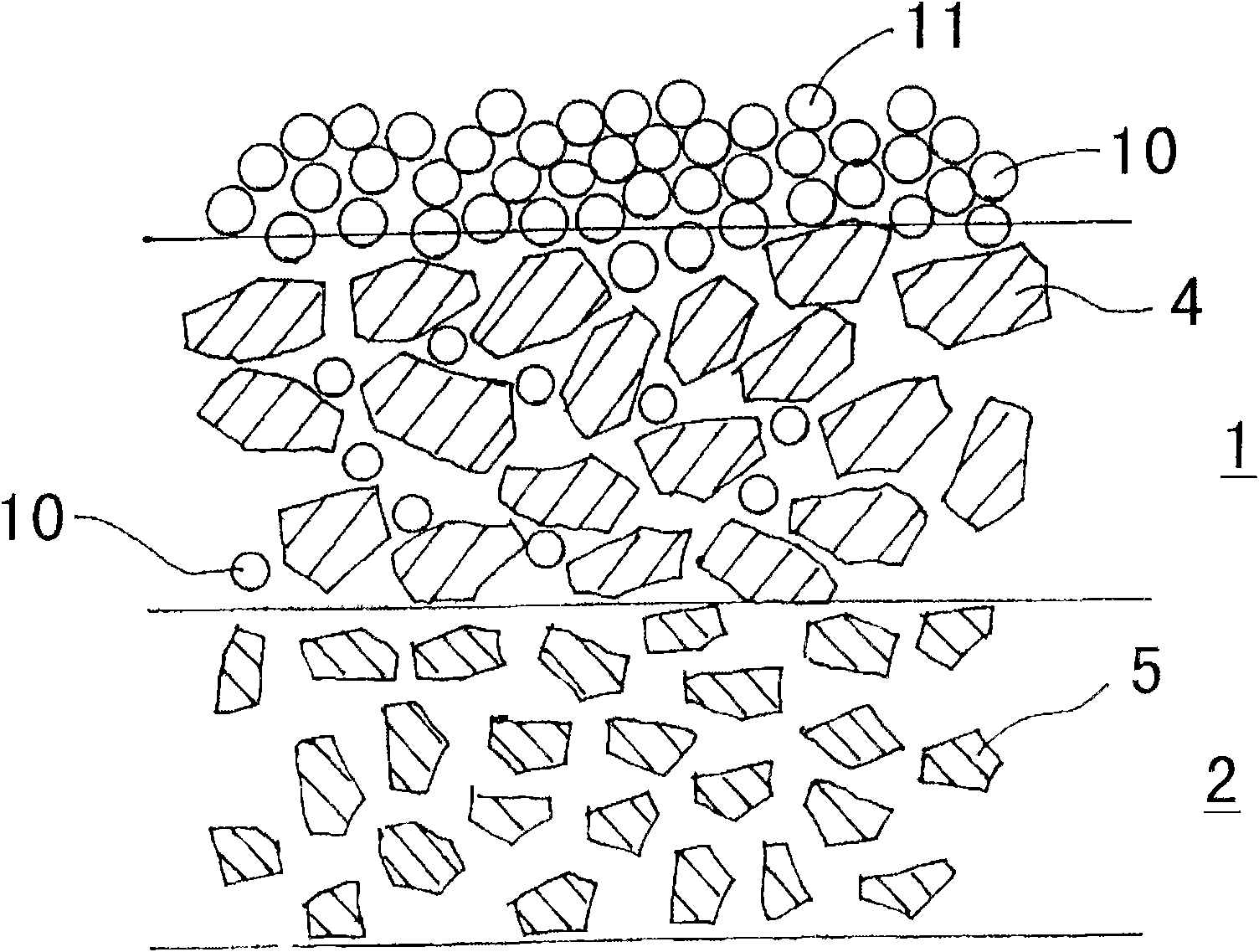

[0032] Table 1 shows the results where the wall thickness was constant at 25 mm, the pore diameter of the macroporous ceramic layer (shown as macroporous layer) and the pore diameter of the microporous ceramic layer (shown as microporous layer) were varied to calculate Inclusion trapping performance and service life in aluminum molten metal. In any embodiment, 8-12% by mass of inorganic binder, 1-2% by mass of forming binder, 5-7% by mass of water, and the balance aggregate will be included. Each layer is continuously molded into a molded body having a predetermined shape. Then, the molded body is dried and then heated to 1200˜1400° C. to melt the binder. Thereafter, the binder was crystallized by cooling to 800°C at a cooling rate of 30-70°C / hour. As a result, a base material is produced in which aggregate particles are connected by a binder in a state where pores are formed betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com