Probe protection structure for machine tool on-line measurement and manufacturing method

A technology for protecting structures and probes, which is applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., and can solve problems such as damage to launch equipment, damage to probe rods, and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

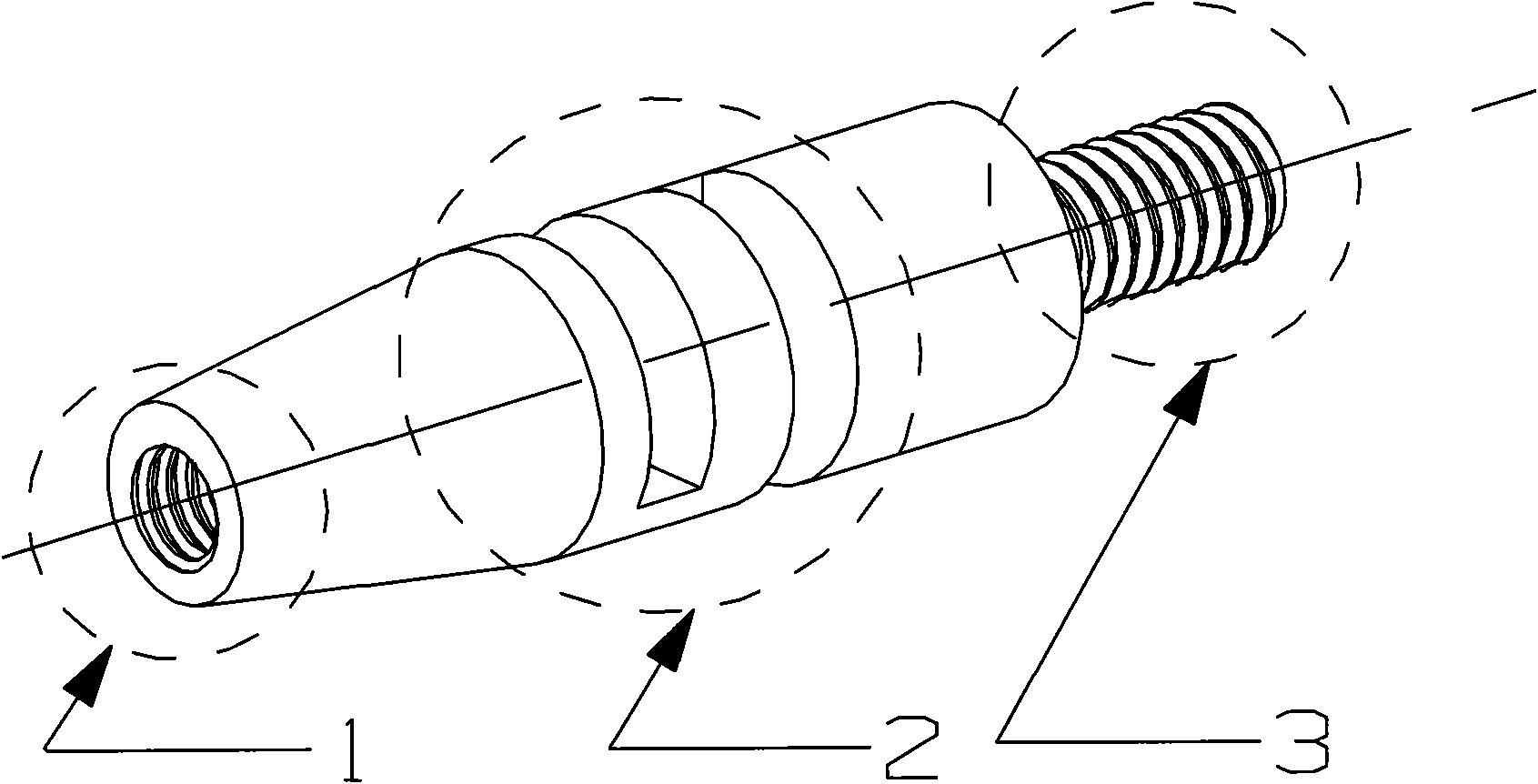

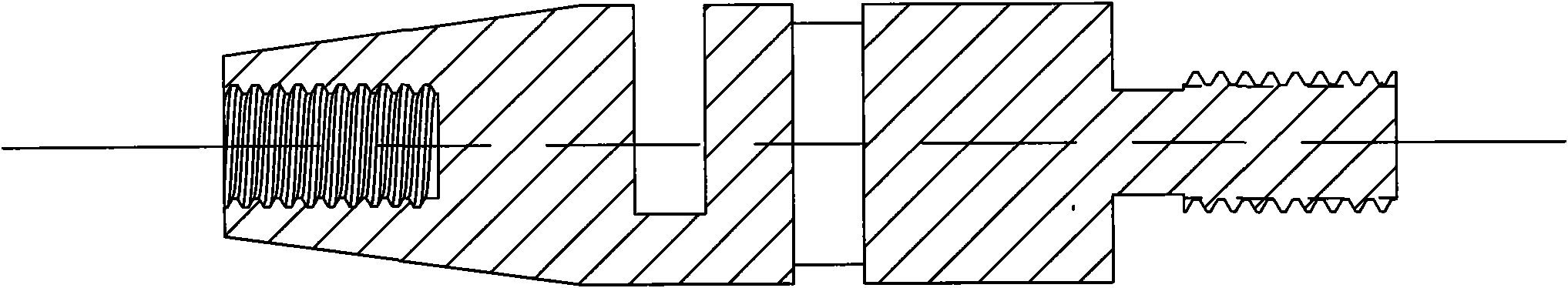

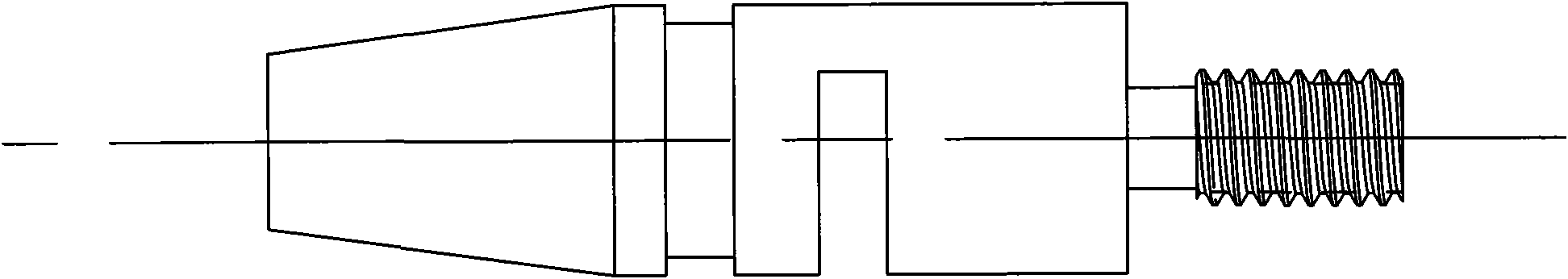

[0017] The probe protection structure used for on-line measurement of machine tools is a metal connection base used to connect the probe and the transmitting device, see Figure 4 , characterized in that the connection base 4 is a combination of a cone 1 and a cylinder 2, see figure 1 : One end of the cone 1 has an internal thread at the center of the small diameter, and the other end of the cylinder 2 has a protruding screw 3 at the center of the circle; there are two radially staggered arc grooves on the cylinder 2 connected to the base 4, and the two arc grooves are axial. to cross, see figure 2 , image 3 , the two arc-shaped grooves have the same size, and the interval thickness of the two grooves is equal; there is an internally threaded hole at the center of the cone 1, which is used to connect the thread at the tail end of the probe rod 5, and the threads of the internally threaded hole 1 and the screw rod 3 are all common threads .

[0018] The cross protection gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com