Integrative solidifying and molding method of minitype unmanned aerial vehicle body and vertical fin and solidifying mold thereof

A curing molding, drone technology, applied in other home appliances, home appliances, household components, etc., can solve the problems of weakening strength and increasing weight, and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

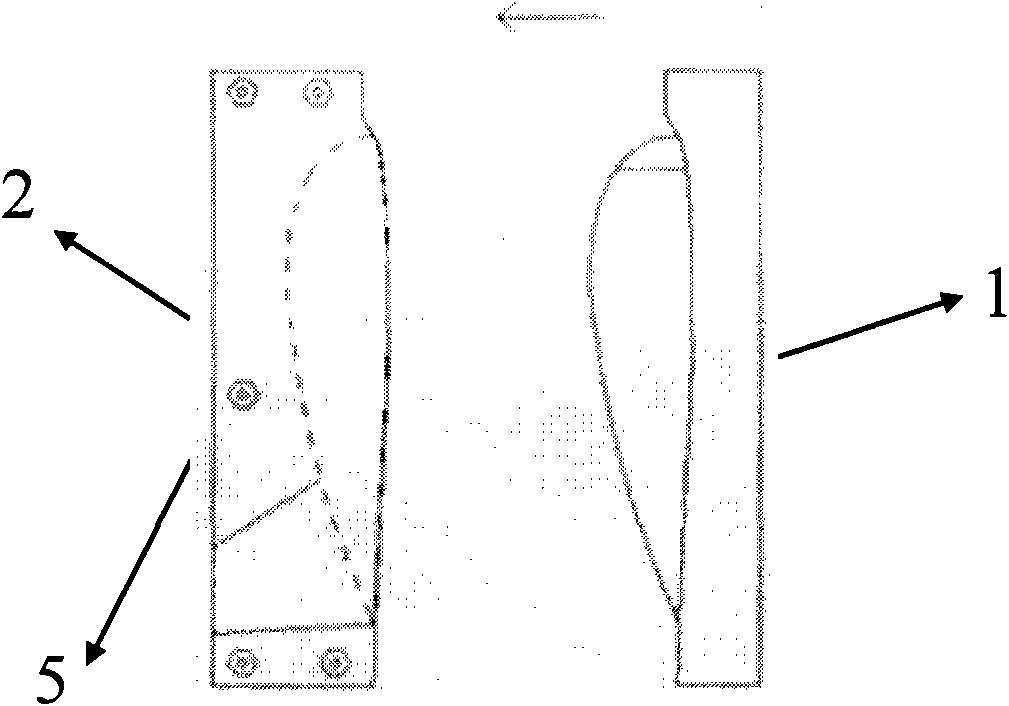

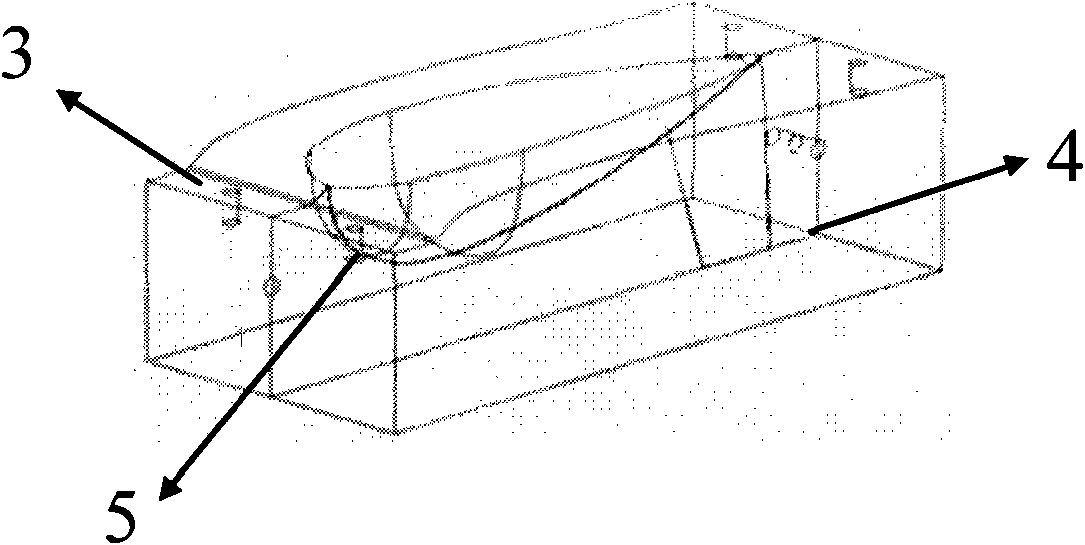

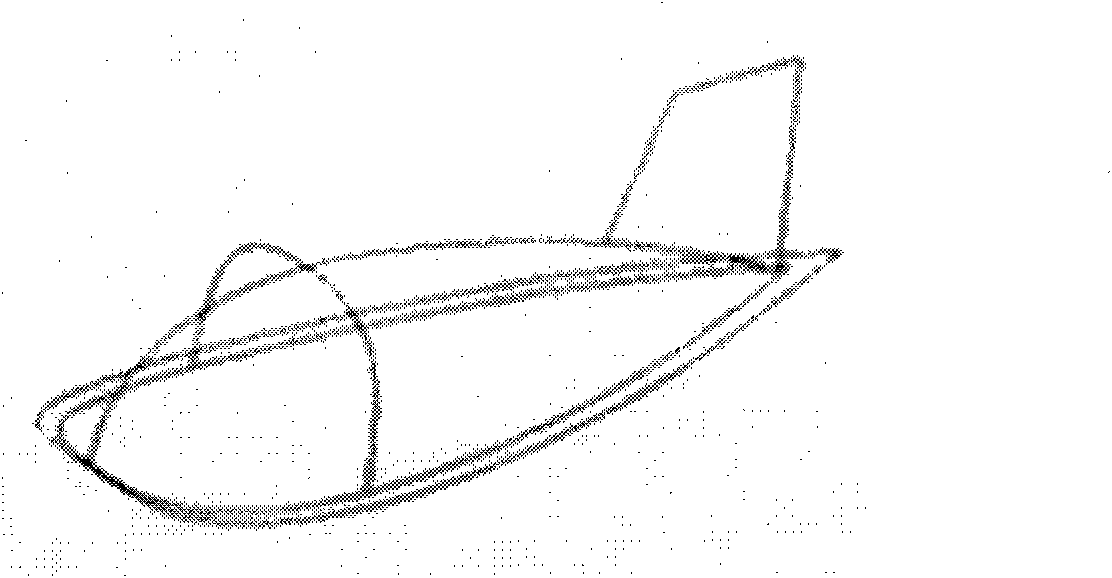

[0039] The present invention is a method for integrated solidification and molding of the fuselage and vertical tail of a micro UAV. The specific steps of the method are as follows: select 1K carbon fiber reinforced bidirectional weaving prepreg adhesive tape, use epoxy resin as the matrix, and integrate multi-axial positioning The molding process method is used to make the thin-shell streamlined fuselage and the overall structure of the vertical tail.

[0040] Step 1: The carbon fiber bidirectional cloth impregnated with epoxy resin glue is cut to have a length above the circumference of one outer surface of the punch;

[0041] Step 2: Cut the length of carbon fiber bidirectional woven cloth that is more than one outer surface of the punch to cover the upper layer of the punch carcass, and use two pieces of fiber reinforced pre-impregnated adhesive tape as the laminate material for the fuselage and vertical tail , put it into the mold, and fix each molded block with bolts;

...

Embodiment 2

[0044] The present invention is a kind of integrated curing molding method of the fuselage and vertical tail of a micro UAV. The specific steps of the method are as follows:

[0045] Aramid fiber bidirectional weaving and phenolic resin are used as the matrix, and the multi-axial positioning integrated molding process is adopted to make the thin-shell streamlined fuselage and vertical tail overall structure.

[0046] Step 1: The carbon fiber bidirectional cloth impregnated with epoxy resin glue is cut to have a length above the circumference of one outer surface of the punch;

[0047] Step 2: Cut the length of the outer surface of the punch to a length greater than the circumference of one outer surface of the punch. Carbon fiber two-way woven cloth is wrapped on the upper layer of the punch body, and two pieces of fiber-reinforced pre-impregnated tape are used as the laminate material for the fuselage and vertical tail. , put it into the mold, and fix each molded block with b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com