Low-emission single-cylinder water-cooling direct injection diesel

A cold direct-injection diesel engine technology, applied to cylinders, cylinder heads, mechanical equipment, etc., can solve problems such as high fuel consumption and poor starting performance at low temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

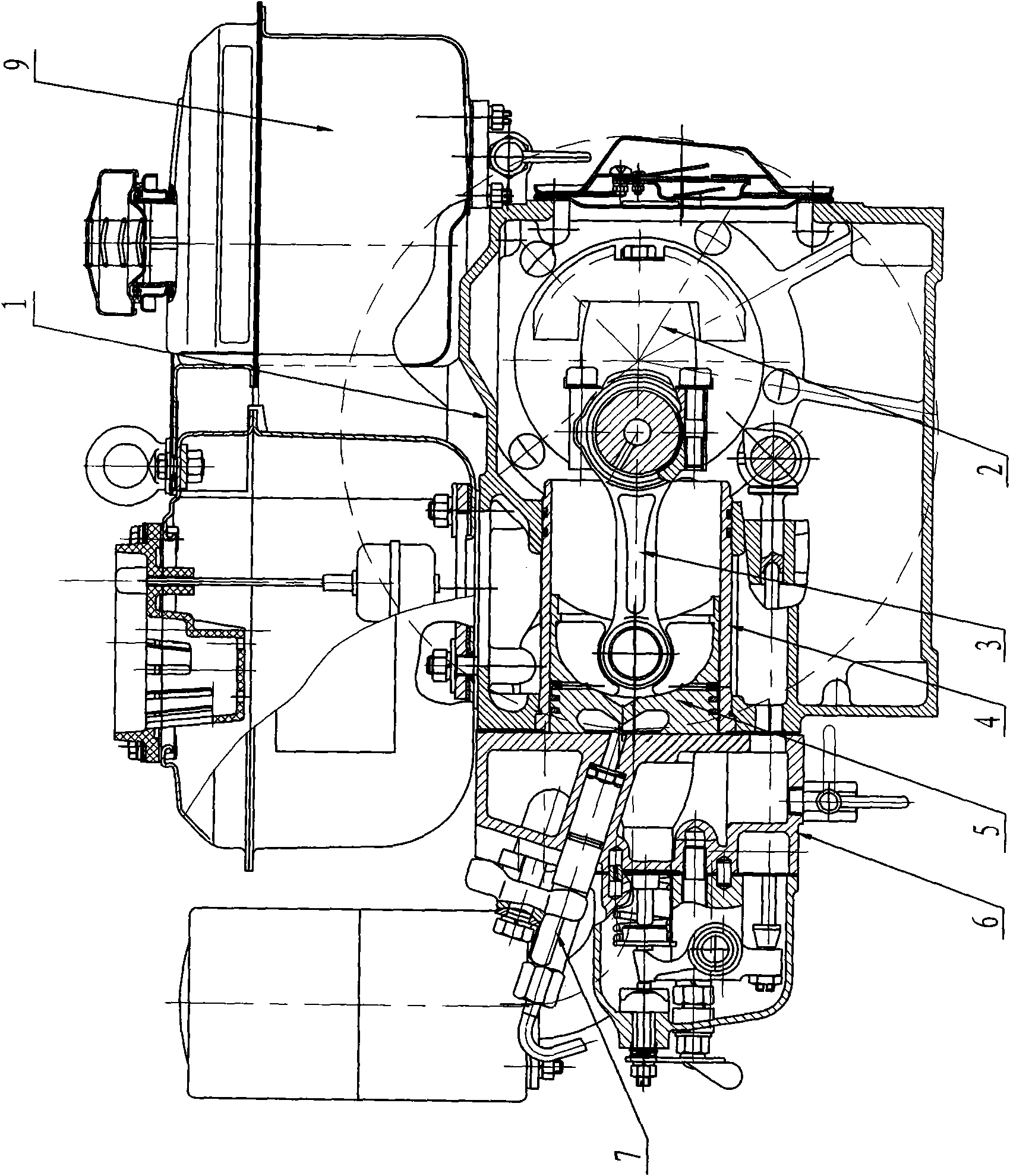

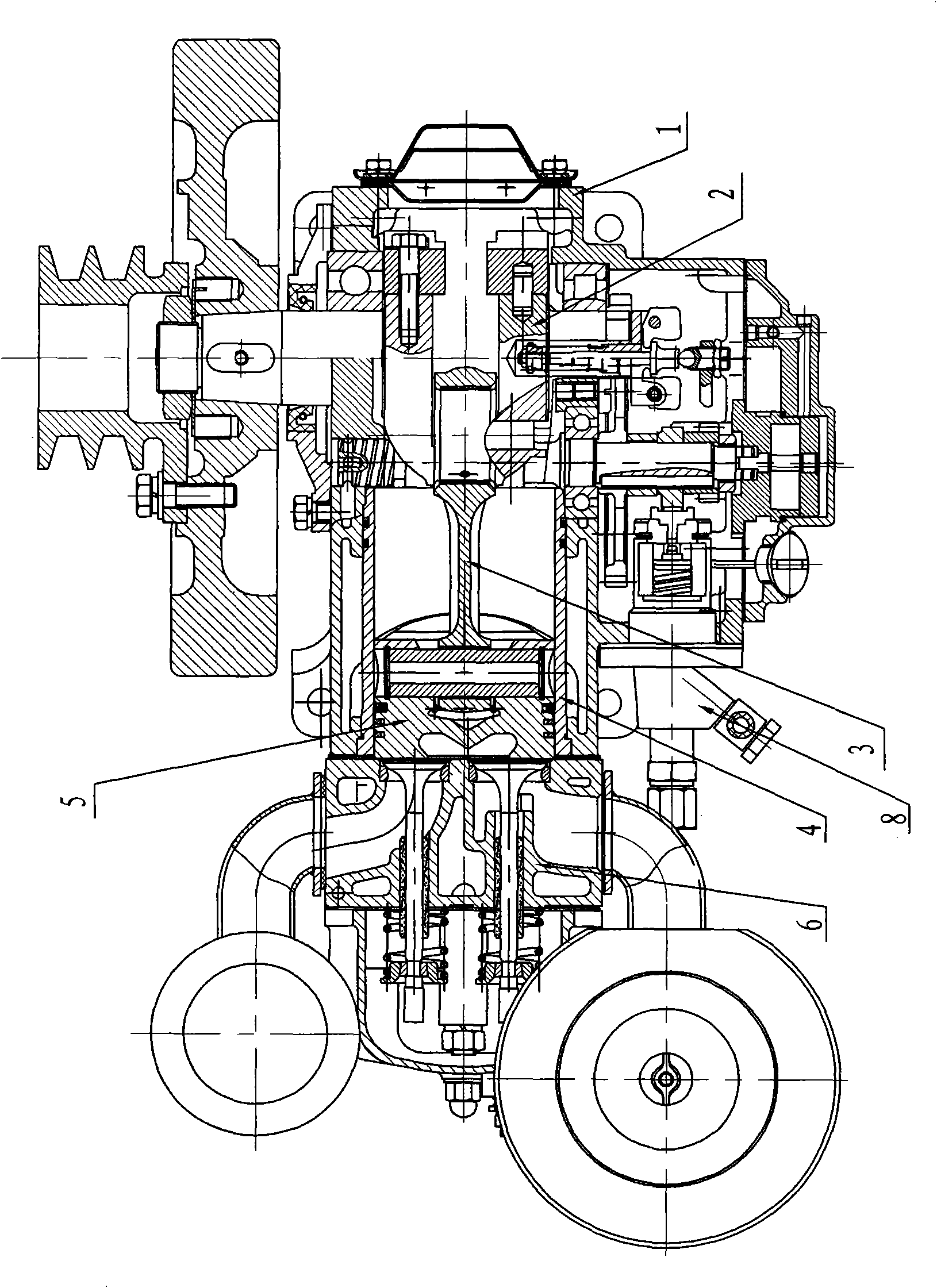

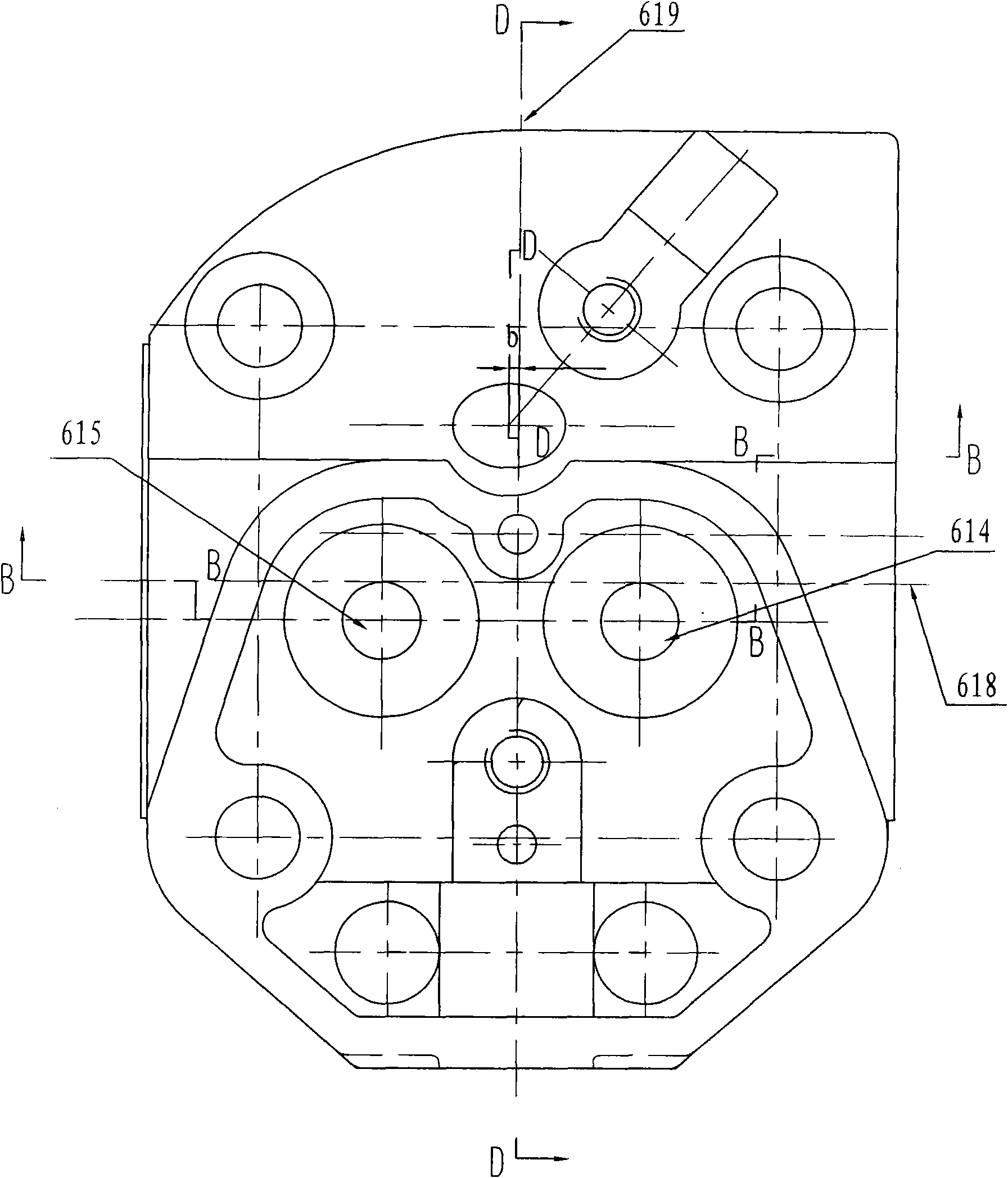

[0015] The low-displacement single-cylinder water-cooled direct-injection diesel engine described in the present invention has a cylinder diameter / stroke of 76 / 65 mm, a power / speed of 3.82 kW / 3000 rpm, and a displacement of 0.295 liters. The industry is commonly known as RZ176 Type single-cylinder water-cooled direct-injection diesel engine, which includes body 1, crankshaft 2, connecting rod 3, cylinder liner 4, piston 5, cylinder head 6, fuel injector 7 and fuel injection pump 8, crankshaft 2 is installed on the body 1 through the bearing seat Above, the cylinder head 6 is installed on the body 1, the big head hole of the connecting rod 3 is installed on the connecting rod neck of the crankshaft 2 through the bearing bush, the small head hole of the connecting rod 3 is hinged with the piston 5 through the piston pin, and the piston 5 is set on the cylinder liner 4, the fuel injector 7 is installed in the fuel injector installation hole 63 on the cylinder head 6, the fuel inje...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com