Colloidal electrolyte for lead-acid battery and preparation method thereof

A colloidal electrolyte, lead-acid battery technology, applied in lead-acid batteries, electrolyte immobilization/gelation, etc., can solve the problems of poor low-temperature discharge capacity, high electrolyte viscosity, short gel time, etc. Good stability and easy perfusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

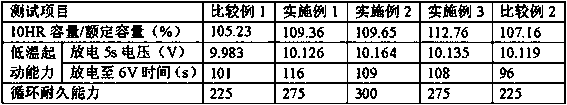

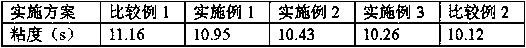

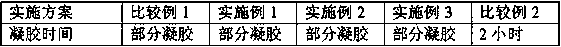

Examples

Embodiment 1

[0027] Composition by weight percentage: sulfuric acid 40%, fumed silica 2.5%, silica sol with a weight concentration of 40% 1.25% (silica 0.5%), lithium oxide 0.3%, sodium hydroxide 0.7%, polyacrylamide 0.04%, sulfuric acid 0.4% stannous, 0.03% cerium sulfate, 0.5% potassium polyaspartate, and the balance is deionized water.

[0028] The preparation process of the electrolyte includes the following steps:

[0029] A: Preparation of fumed silica mother liquor: Add deionized water 5 times the weight of fumed silica into a stirred tank with a stirring and slitting function of speed greater than 3000 revolutions / min, and then add formula amount of sodium hydroxide and hydroxide Lithium, stir and dissolve, gradually add the formula amount of fumed silica, after adding all the fumed silica, continue to stir for 20 minutes, then add the formula amount of polyacrylamide, continue to stir for 20 minutes, to prepare the fumed silica mother liquor;

[0030] B: Preparation of dilute sulfuric a...

Embodiment 2

[0033] Composition by weight percentage: sulfuric acid 40%, fumed silica 1.5%, 40% silica sol 3.75% (silica 1.5%), lithium hydroxide 0.6%, sodium hydroxide 0.4%, polyacrylamide 0.03% , 0.3% stannous sulfate, 0.02% cerium sulfate, 0.6% potassium polyaspartate, and the balance is deionized water.

[0034] The preparation method is the same as in Example 1.

Embodiment 3

[0036] Composition by weight percentage: sulfuric acid 42%, fumed silica 1%, 40% silica sol 5% (silica 1.5%), lithium hydroxide 0.4%, sodium hydroxide 0.4%, polyacrylamide 0.02% , 0.5% stannous sulfate, 0.02% cerium sulfate, 0.7% potassium polyaspartate, and the balance is deionized water.

[0037] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com